Do you have a question about the Columbia MPH SERIES and is the answer not in the manual?

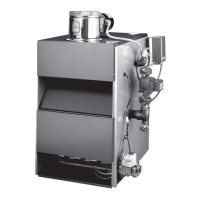

Overview of the Columbia Multi-Pass Horizontal (MPH) boiler series and its applications.

Guidelines for selecting and preparing a suitable boiler room location.

Instructions for properly venting the boiler and flue piping.

Details on the factory-installed boiler jacket and its installation.

Procedures for mounting the burner onto the boiler.

Information regarding the boiler's drain connections and their use.

Details on standard and secondary low water cut-off devices for boiler safety.

Specifics on Warrick 26C1D1C probe type LWCO for steam applications.

Instructions for piping and maintaining the boiler's water gauge.

Description of operating and safety limit pressure controls for steam units.

Explanation of Aquastat controllers for regulating hot water boiler temperatures.

Details on safety and relief valves for steam and hot water applications.

Piping instructions for steam and hot water supply lines.

Specifics on connecting hot water return lines and expansion tanks.

Guidance on connecting and treating feed water for the boiler.

Information on connecting and operating boilers equipped with heating coils.

Guidance for connecting the oil supply to the burner.

Requirements and guidelines for gas supply piping installation.

Procedure for removing oil and grease from new steam boilers by skimming.

Using chemical compounds for cleaning steam boilers.

Essential checks and information required before starting the boiler.

Step-by-step instructions for starting the boiler safely and correctly.

Procedure for safely shutting down the boiler.

Explanation of operating and safety limit pressure controls for steam boilers.

Details on standard and optional low water cut-off devices for steam boilers.

Proper installation, safety, and operation of safety valves.

Description of operating and safety limit Aquastat controllers for hot water boilers.

Details on the McDonnell & Miller 750-MT-120 low water cut-off for hot water boilers.

Guidelines for installing and maintaining relief valves on hot water boilers.

Guidelines for maintaining manufacturer literature, spare parts, and log books.

Procedures for cleaning boilers and heating surfaces for peak efficiency.

Daily tasks for checking and maintaining boiler components and operation.

Weekly tasks for checking boiler systems, fuel valves, and ignition.

Monthly tasks for testing interlocks, safety valves, and inspecting heating surfaces.

Semiannual checks of burner components, flame failure systems, and internal inspections.

Annual maintenance tasks including testing controls, cleaning LWCO, and checking electrodes.

Guidelines and warnings for maintaining and replacing boiler gauge glass.

Instructions for performing boiler blowdown to remove dissolved solids.

Maintaining optimal pH levels for boiler water to prevent corrosion and scale.

Methods for managing dissolved oxygen in boiler water to prevent corrosion.

Using sodium sulfite for chemical removal of dissolved oxygen in boiler water.

Understanding and controlling suspended and dissolved solids in boiler water.

Maintaining sufficient alkalinity for protection against acidic corrosion.

Role of phosphates in reacting with calcium hardness in boiler water.

Managing water hardness to prevent scale and sludge formation.

Preventing oil from entering boiler water to avoid foaming and sludge.