1960 SERVICE MANUAL

SERVICE NOTES

1. When replacing parts or circuit boards, clamp the lead wires around the terminals

before soldering.

2. When replacing a high wattage resistor ( >0.5 W metal oxide film resistor) in the

circuit board, keep the resistor about 1 cm (1/2") away from the circuit board.

3. Keep wires away from high voltage or high temperature components.

4. Keep wires in their original positions so as to minimize inteference.

SAFETY TEST

Before returning a serviced monitor to the customer, a thorough safety test must be

performed to verify that the monitor is safe to operate without danger of shock.

Always perform an AC current leakage check on the exposed metallic parts, such as

screw heads, as follows:

1. Plug the AC line cord directly into a rated AC. Do not use a Line Isolation

Transformer during this check).

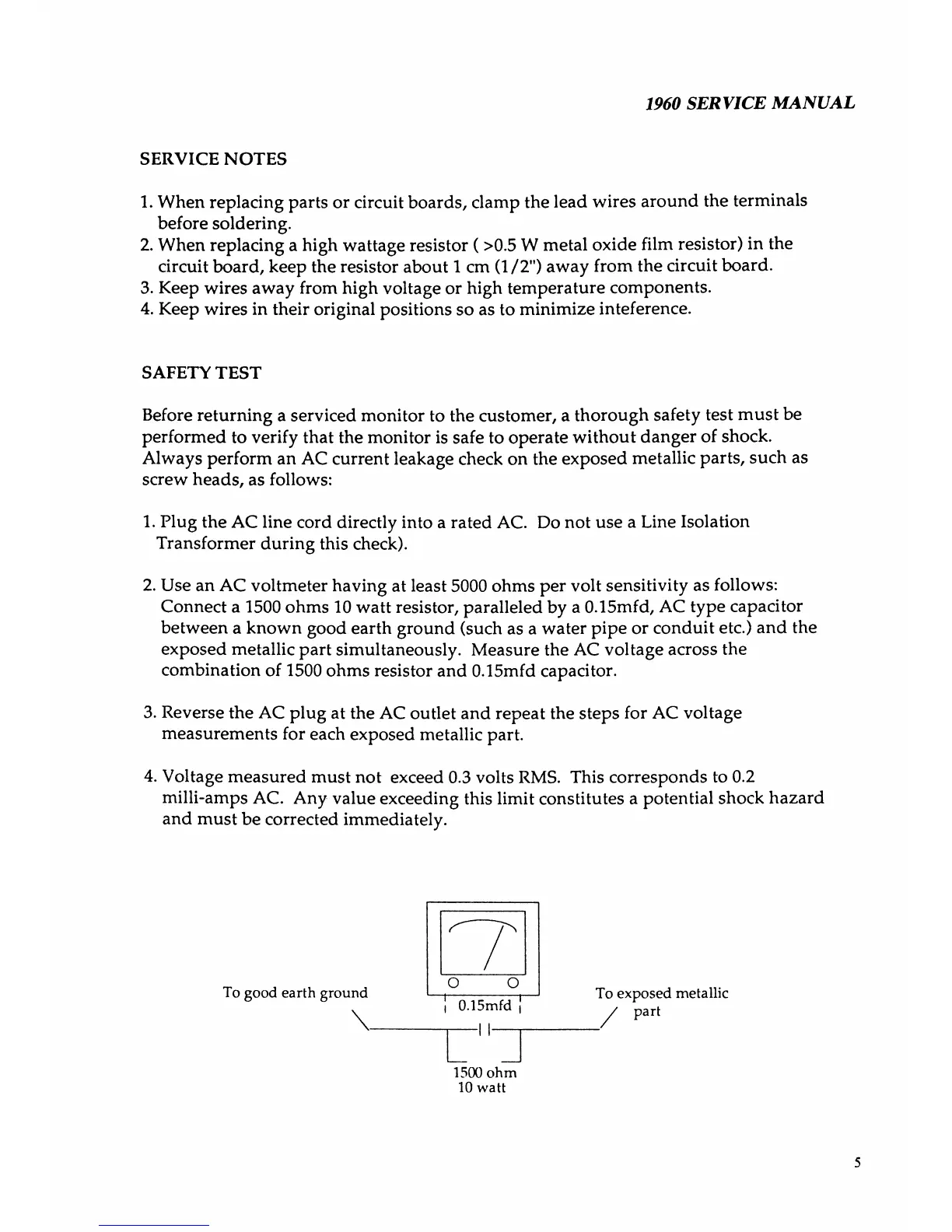

2. Use an AC voltmeter having at least 5000 ohms per volt sensitivity as follows:

Connect a 1500 ohms 10 watt resistor, paralleled by a 0.15mfd, AC type capacitor

between a known good earth ground (such as a water pipe or conduit etc.) and the

exposed metallic part simultaneously. Measure the AC voltage across the

combination of 1500 ohms resistor and 0.15mfd capacitor.

3. Reverse the AC plug at the AC outlet and repeat the steps for AC voltage

measurements for each exposed metallic part.

4. Voltage measured must not exceed 0.3 volts RMS. This corresponds to 0.2

milli-amps AC. Any value exceeding this limit constitutes a potential shock hazard

and must be corrected immediately.

To good earth ground

To exposed metallic

/ Part

1500 ohm

10 watt

5

Loading...

Loading...