87

* If the engine was started cold, let it

warm up for approximately 2 minutes

and then press the START/RUN valve

(2). If the engine is warm, the START/

RUN valve can be pressed immediately.

* The installation is now ready to operate.

Check that all the hoses and tools have

been connected correctly and open the

desired air outlet valves.

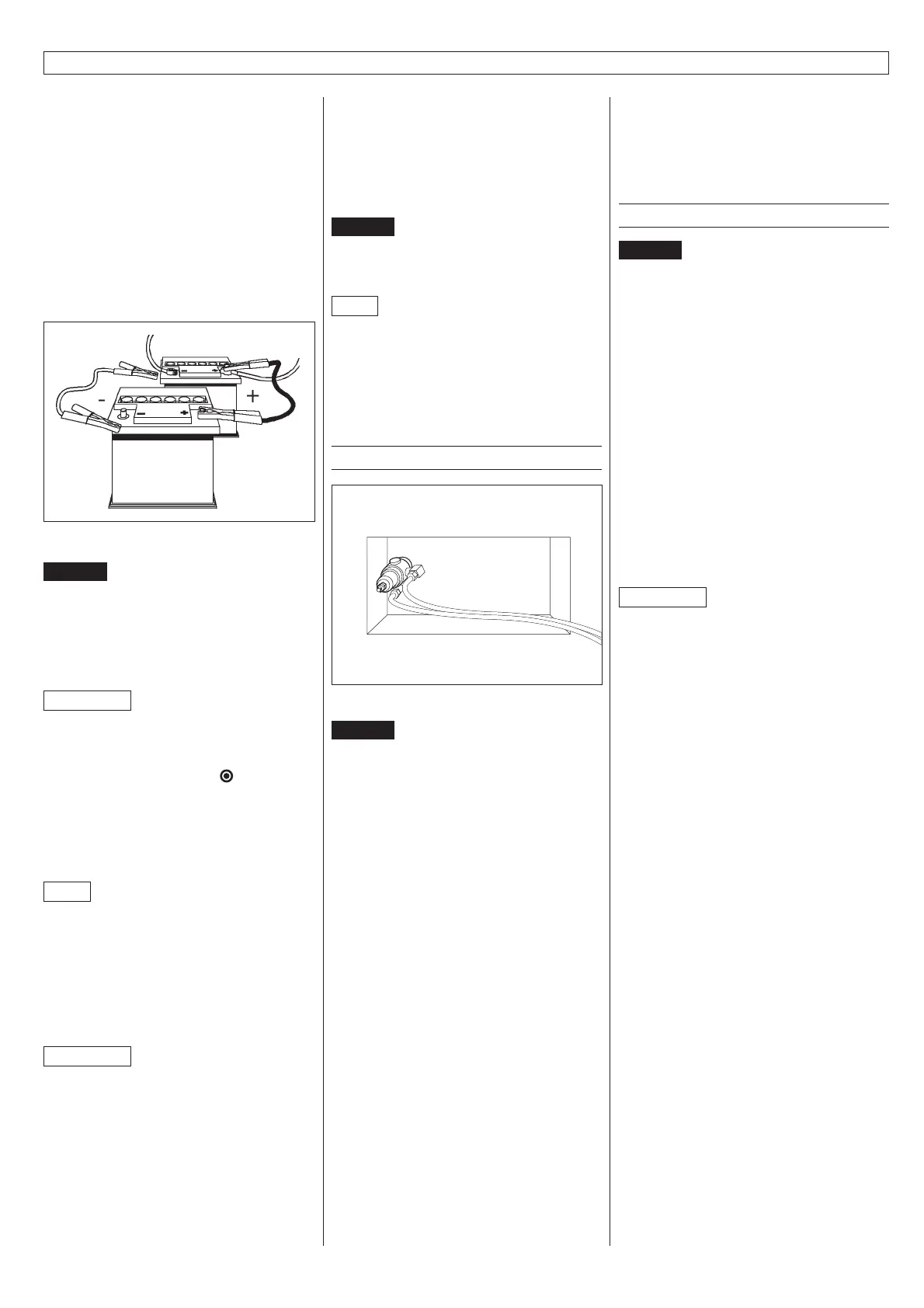

Start-up using jumper cables / auxiliary

batteries

Fig. 20

Danger

Longer operation with an auxiliary

battery or jumper cables connected can

lead to sudden emissions of gas. An

inflammable air / gas mixture is formed.

Explosion hazard!

Attention

Serious damage can be caused to the

electrical system if wrongly connected.

* Ignition switch in position

(Off-Aus)

* First connect positive terminal then

negative terminal (ground).

* Start as described in section “Starting up

the compressor.”

Note

After the engine has started, first

disconnect the negative cable (ground)

and then the positive cable.

Cold-starting diesel engines with ether

fuel systems

Attention

For cold starts (winter operation) Start-

pilot or any other starting aid may be

sprayed directly into the engine air filter

(Attention: do not confuse this with the

air filter for the screw compressor). (It is

essential that the engine operating

manual be observed.)

Never use the ether cold-starting aid

while the engine is running, as this can

lead to serious damage.

Before using the ether cold-starting aid,

carefully read the instructions and the label

on the tank.

Danger

Never store the ether tank at tempera-

tures above 70

°

C.

Note

Follow the instructions for operating the

compressor at an ambient temperature of

less than 0

°

C, in Chapter 5, Transport and

Installation on Site, in this operating

manual.

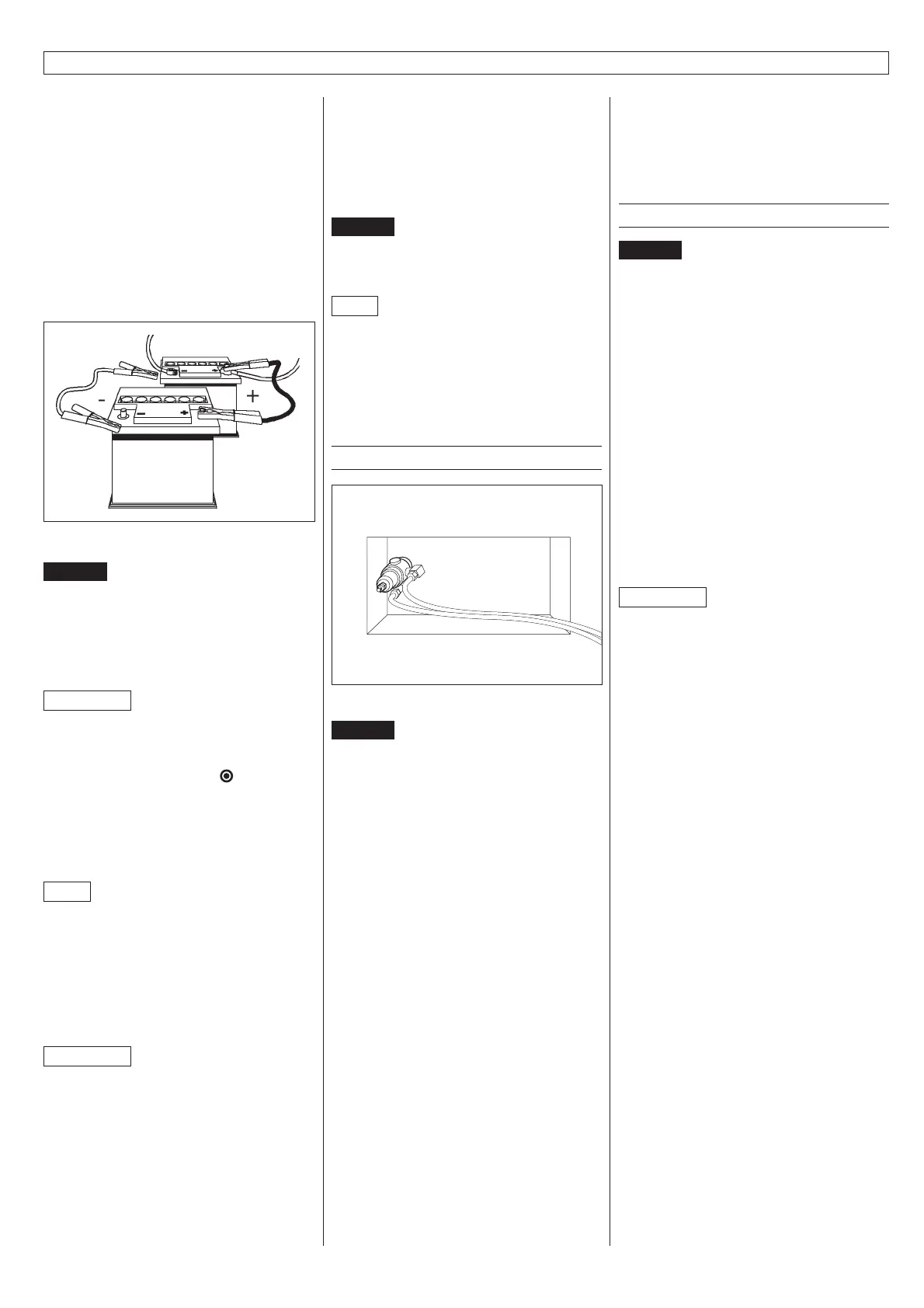

7.4 Setting the operating pressure

Fig. 21

Danger

The setting of the operating pressure

may only be carried out by a specialist.

The operating overpressure of the screw

compressor is set by the manufacturer

(see the identification plate on each

compressor).

Pressure values between 5 or 8 bar and

the operating overpressure can be set in

accordance with the identification plate on

each compressor. Pressure values higher

than this are not permitted.

Operating pressure is set by a specialist

at the controller.

* Remove counternut below the control

knob of the regulator.

* Raise pressure by turning the adjusting

knob of the regulator clockwise

(towards +).

* Lower the pressure by turning the

adjusting knob of the regulator

anticlockwise (towards -).

* In order to lower the pressure, open an

air discharge valve.

* After altering the pressure, lock the

adjusting knob using the knurled nut.

This readjusted operating pressure is to

be checked using the pressure gauge on

the instrument panel at 100% air discharge

and maximum engine speed.

7.5 Monitoring / fault

Danger

Bridging the safety switch in the

automatic monitoring system is not

permitted!

The display on the pressure gauge may

not go further than the red line.

When the “Fault” indicator lamp lights up,

the screw compressor is automatically shut

down when the following faults occur:

* Fuel shortage

* Compressor temperature too high

* Engine oil pressure too low

* Engine oil temperature too high

After one of these faults, it is only

possible to restart the machine after the

fault that caused the machine to be shut

down has been corrected.

Attention

Disconnect the battery or generator only

when the engine is not running.

* Switch off the machine if the

compressed air transports oil spray or if

excessive oil is consumed. (Refer to the

trouble-shooting section)

* Check that the "battery charge" pilot

lamp is not illuminated. If it glows, even

weakly, refer to the trouble-shooting

section.

* Check that the air pressure (7) assumes

a value within the permissible pressure

range.

If the machine cuts out, before switching

off at the ignition switch (1) carry out the

following checks:

* Interrupt the electric connection to the

engine oil pressure switch immediately

after the engine has cut out and leave it

in the interrupted state.

If the "fault" pilot lamp goes out

immediately this indicates that either a

too low engine oil pressure or a lack of

fuel or a defective engine has led to the

cut-out.

* If the light continues glowing this

indicates that an excessive engine

temperature or compressor temperature

led to the cut-out.

7. Putting the compressor into operation

Loading...

Loading...