88

In order to trace the origin of the fault,

interrupt the engine oil temperature

switch (with the engine oil pressure

switch still switched off). If the lamp now

goes dark this indicates that the problem

is related to the oil temperature.

* If the lamp continues glowing the fault

is located somewhere else. In this case

reconnect the engine oil temperature

switch and interrupt the connection to

the compressor temperature switch. If

the lamp goes dark the compressor

temperature has led to the cut-out.

* Reconnect all electrical connections

once the fault has been identified in

order to re-establish the function of the

protective elements. Also reconnect

the engine oil pressure switch.

* Switch the ignition switch to its position

(Off-Aus).

Note

These checks must be carried out

immediately after the installation has

cut out as the protective circuits reset

themselves after cooling down.

If the ignition switch is pushed to the very

left while the machine is running it will be

switched off.

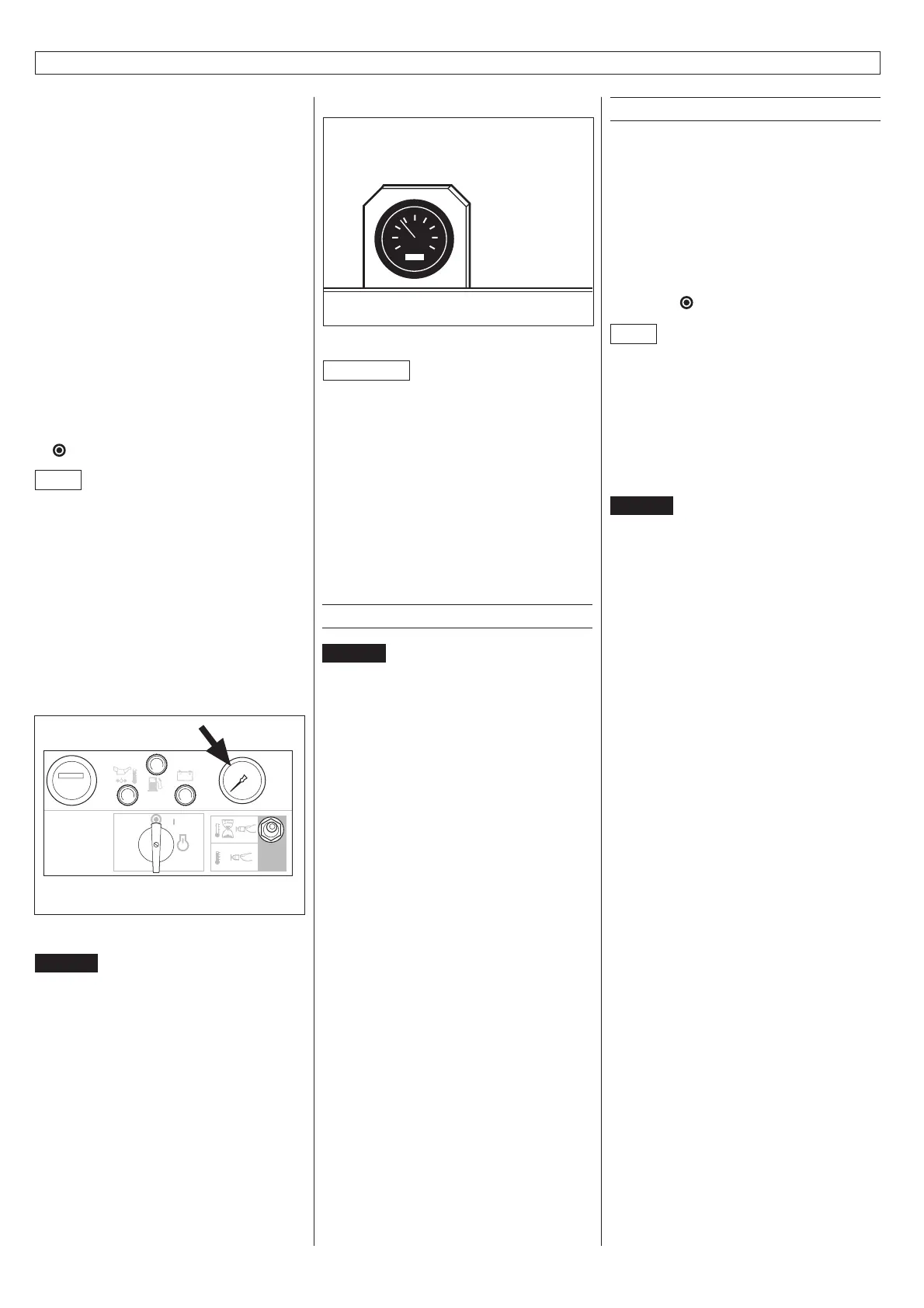

Pressure gauge for display: “Operating

pressure”

Fig. 22

Danger

Do not operate the compressor at

pressures above the permissible

operating pressure.

The pressure gauge shows the operating

pressure of the compressor.

The permissible operating pressure is

indicated on the nameplate! The safety

valve pressure is indicated on the pressure

gauge by a red mark.

Display for compressor temperature

Fig. 23

Attention

Do not operate the compressor above

the permissible final compression

temperature.

The final compression temperature is

measured with the temperature sensor and

displayed on the thermometer (option).

The compressor is automatically shut

down when the permissible final

compression temperature is exceeded.

7.6 Operation

Danger

Only operate the compressor at the

permissible operating pressure and at

the permissible temperature.

Only use the compressor for its

intended purpose (see Chapter 1.2 of

this operating manual) in order to avoid

residual risk for persons and assets.

Only operate the compressor in a safe,

functioning condition.

All components, hoses etc. fitted must

be of the correct size and designed for

the specified operating pressure and

temperature.

When working with compressed air,

wear suitable protective clothing (e.g.

protective suit, safety goggles, etc.).

Wearing ear muffs may impair

communication between persons.

Warnings may not be heard. Inform

supervisor.

Check the compressor regularly.

Leaking condensation contains a

proportion of oil and must be collected

and disposed of under safe conditions.

Condensation must not enter the

soil or the rivers. Major quantities of

condensation accumulate particularly

in versions with aftercoolers for

processing compressed air. Provide a

collecting basin.

7.7 Shutdown

In order to shut down the compressor:

* Close air discharge valves. The screw

compressor reduces the speed of the

engine back to idling speed after the

preset final pressure has been reached.

* Allow the screw compressor to idle for a

few minutes.

* Return the ignition switch (1) to the

position

(Off-Aus).

Note

This switch can also be used as an

emergency stop switch. No other switching

off method is provided.

After the installation has come to a

standstill all the air is automatically blown

out of the pressure tank via the blow-off

valve.

Danger

It is important that you ensure that the

pressure is completely blown off via the

blow-off valve.

Should this not be the case, open the air

outlet valves, identify the fault and

correct it.

7. Putting the compressor into operation

Loading...

Loading...