MODEL 36, TYPE B & C

SINGLE RANGE TENSIONCELLS

INSTRUCTION MANUAL A-279

6

Copyright 2023 - Revised Comptrol All Rights Reserved

4. Connect the positive (+) output lead to Pin D and the

negative (-) output lead to Pin C. (See Figure 4)

5. Repeat Steps 1 through 4 of the electrical wiring

procedure for the Tensioncells mounted on the other

end of the measuring roll.

II-G ELECTRICAL ZERO ADJUSTMENT

(Read the complete Electrical Zero Adjustment

procedure before proceeding with the adjustment.)

1.

Disengage strip from the measuring roll so that no

tension force is applied to the loadcell.

2.

Connect a voltmeter to Pins C and D (See Figure

4)

3.

Apply 24-volt DC electrical power to the loadcell

observing the correct polarity. [Plus (+) to Pin D

and minus (-) to Pin C]. Do not exceed the

maximum rated input voltage.

NOTE: Allow 20 minutes for the loadcell to warmup

before taking first readings to insure accurate readings.

4.

Measure the output voltage of the LVDT between

the Green and Blue leads for each Tensioncell with

a voltmeter with a sensitivity of at least 100,000

ohms per volt. The output voltage should be

between 0.5 and 6.5 volts.

5.

Since Comptrol Tensioncells cannot be

mechanically zeroed, refer to the Control Manual

for zeroing out the tare weight voltage.

II-H FULL LOAD ADJUSTMENT

After the loadcell has been zeroed, a pull test can be

made to check the output voltage of the loadcell at full

load. (See calibration sheet for voltage output)

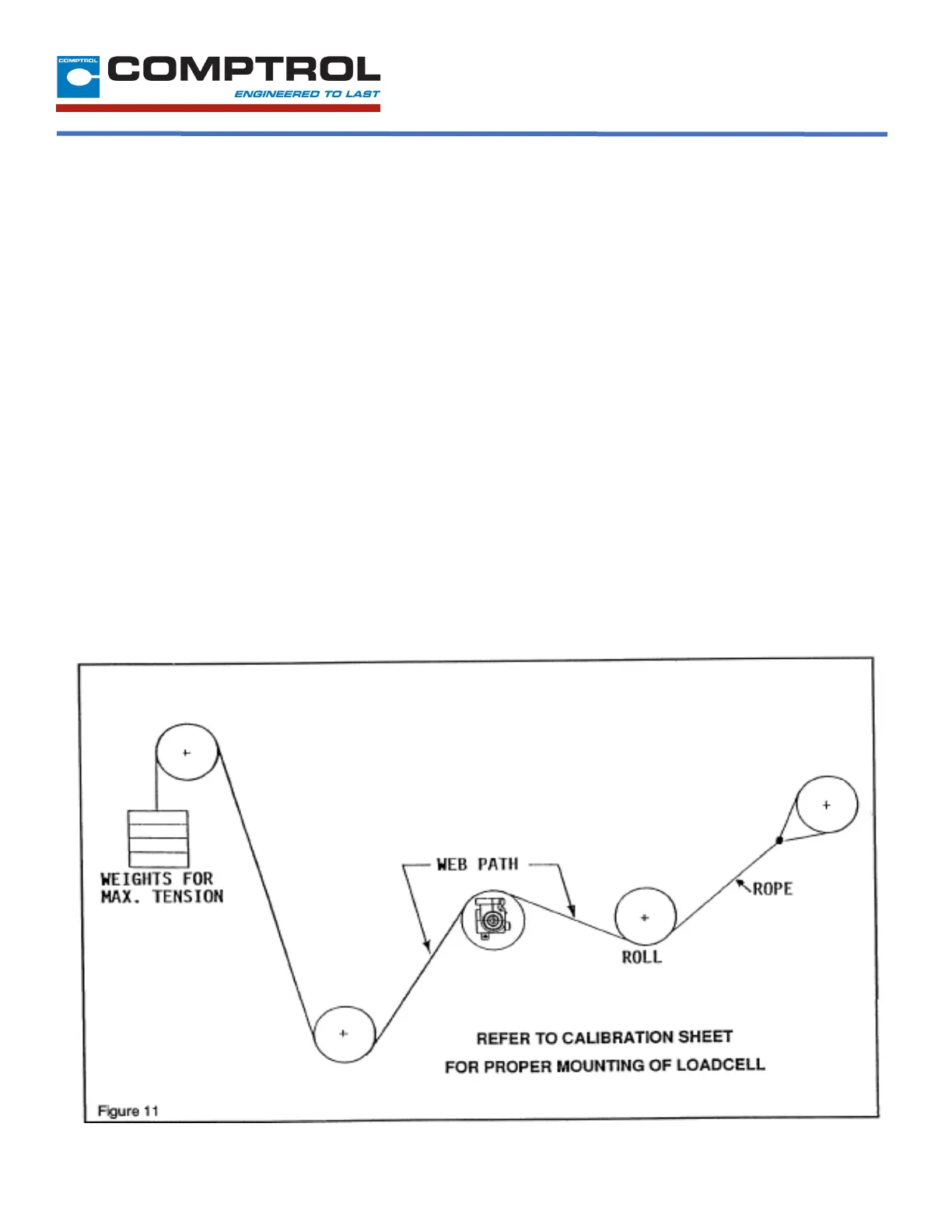

1. Run a non-stretchable rope over the center of the

tension roll simulating the web path. (NOTE: the rolls

should be free to turn)

2. With one end of the rope secured, hang a known

weight, equally over the roll so that the total tension is

equal to the maximum strip tension specified on the

calibration sheet, at the other end. (See Figure 6)

Loading...

Loading...