© 2000 CONTRIVE • B1401.EN 0211 9 www.contrive.it

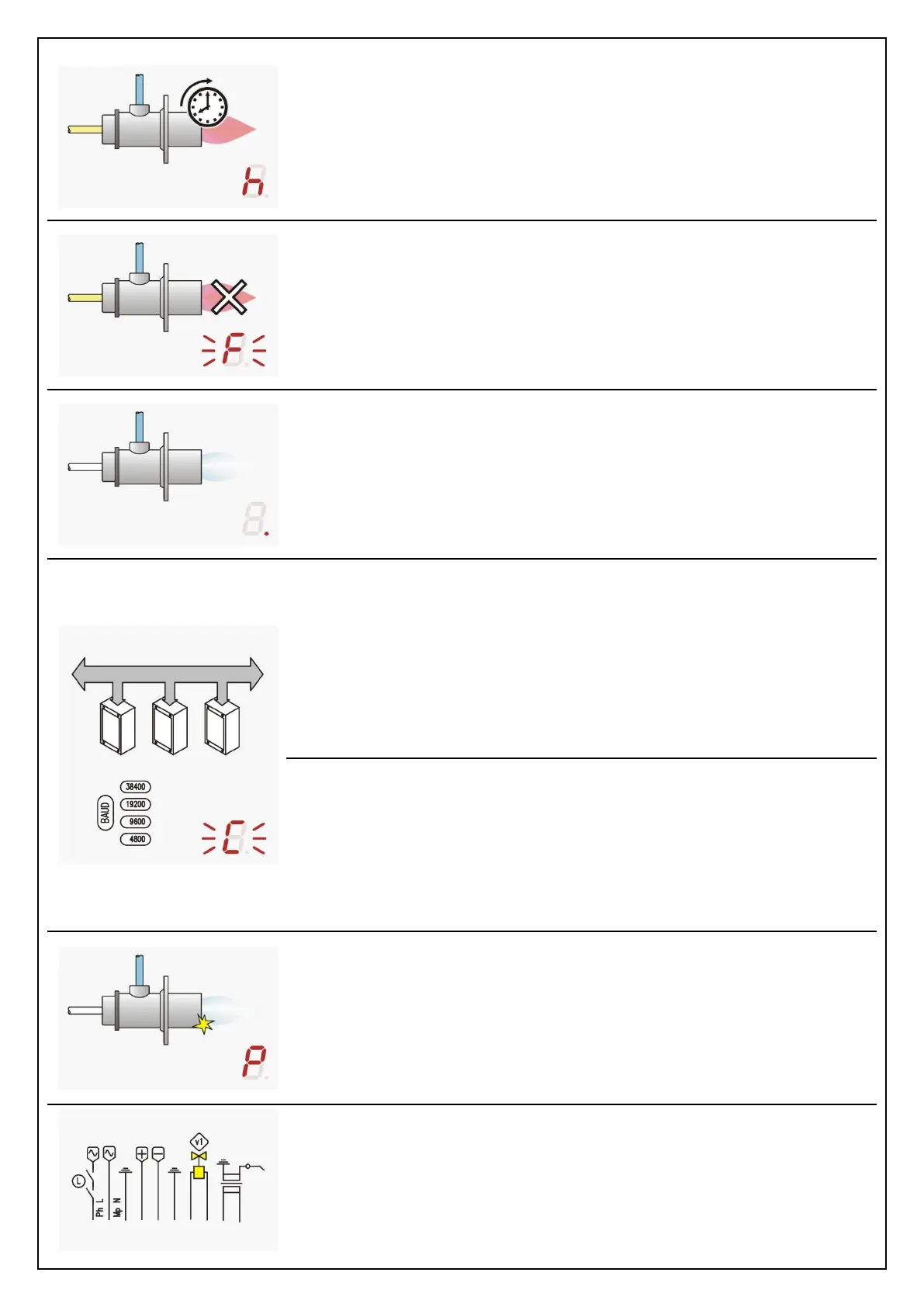

Q510 – AUTO SHUT-OFF MODE

Behavior after an automatic shut-off. In AUTOMATIC mode a complete burner

restart cycle is deployed, performing the test of the whole system, as per Standard

requirements, within 24 hours of continuous operation.

In MANUAL mode the burner waits for reset.

Q512 – FLAME LOSS

Determines the behavior at flame loss during normal burner operation.

For burners with occasionally unstable flame signal a single recycle (including

prepurge) or direct respark can be attempted. The setting is to be determined on

the basis of burner capacity and relevant application standard.

Q602 – POSTPURGE TIME

Follow EN 676 requirements to set correct postpurge time in forced draught

burners. Any air valve and/or butterfly valve controlled by external process must

be kept open during the whole postpurge time.

During this time an illegal flame test is carried out.

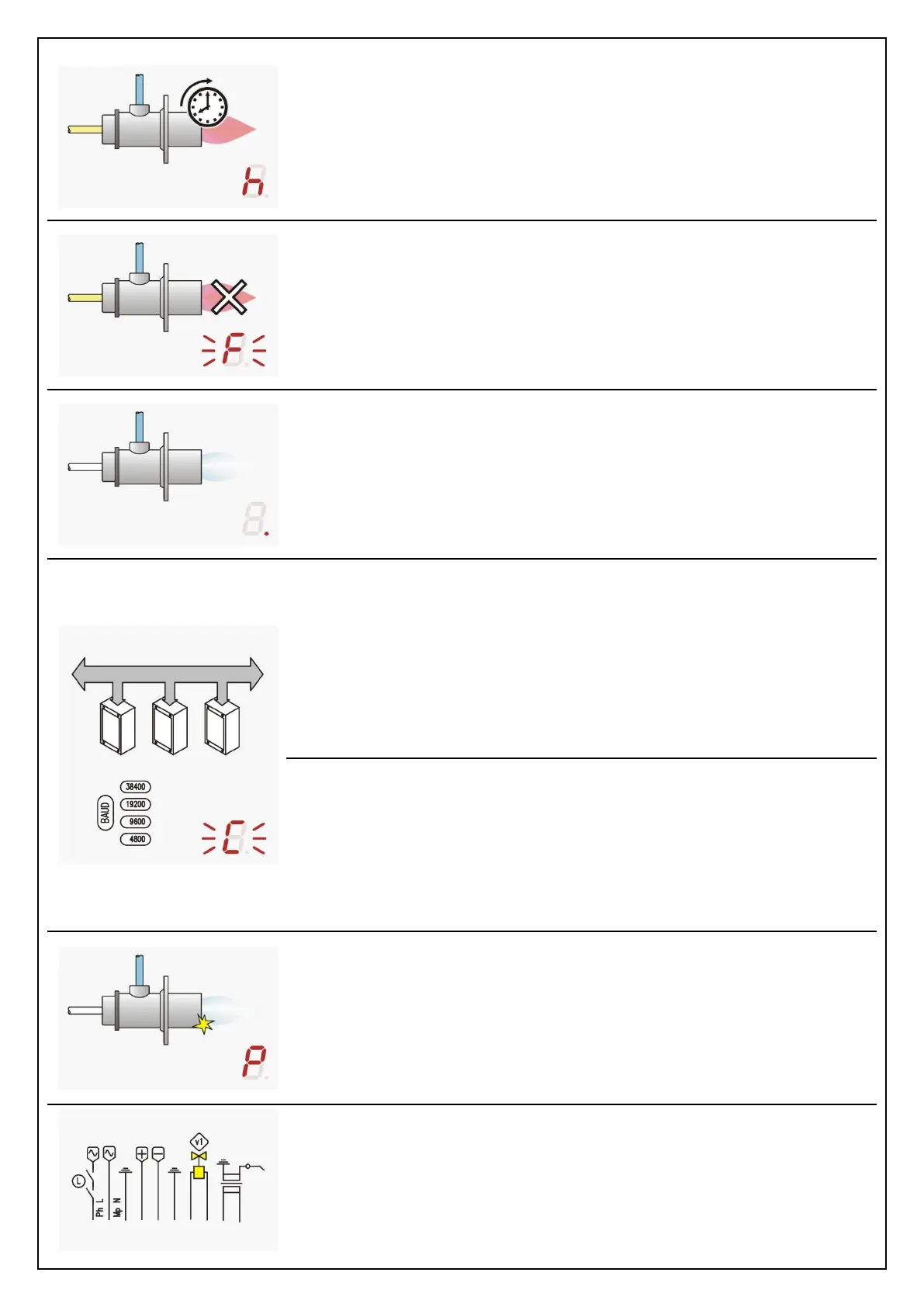

Q701 – ZONE (SEGMENT)

Communication identifier: group or zone belonging the burner control.

All alphanumeric (uppercase/lowercase) characters are valid identifiers.

Q702 – UNIT (NODE)

Communication identifier: burner control unit within a given area, group or zone.

All alphanumeric (uppercase/lowercase) characters are valid identifiers.

Q703 – BAUD RATE

Communication baud rate: 4800, 9600, 19200, 38400.

Q704 – COMMUNICATION TIMEOUT

Communication timeout up to 1000 seconds (4” step). Set 0 to disable.

Q801 – BURNER TYPE

Selecting OIL type burner the ignition device will be activated also during the

prepurge to allow the detection of oil leakage that will be ignited, leading to an

illegal flame detection. Application and settings must be made in accordance to

EN 230 (or other relevant standard) requirements.

Q001 – POWER SUPPLY VOLTAGE

Power supply must be wired at terminal 01 and 02, for burner control unit and

loads (gas valve and ignition transformer), both protected by the embedded fuse.

Optional safety interlock limits could be wired on the main supply phase.

Loading...

Loading...