3CA/CF/CP IO&M B51181-002

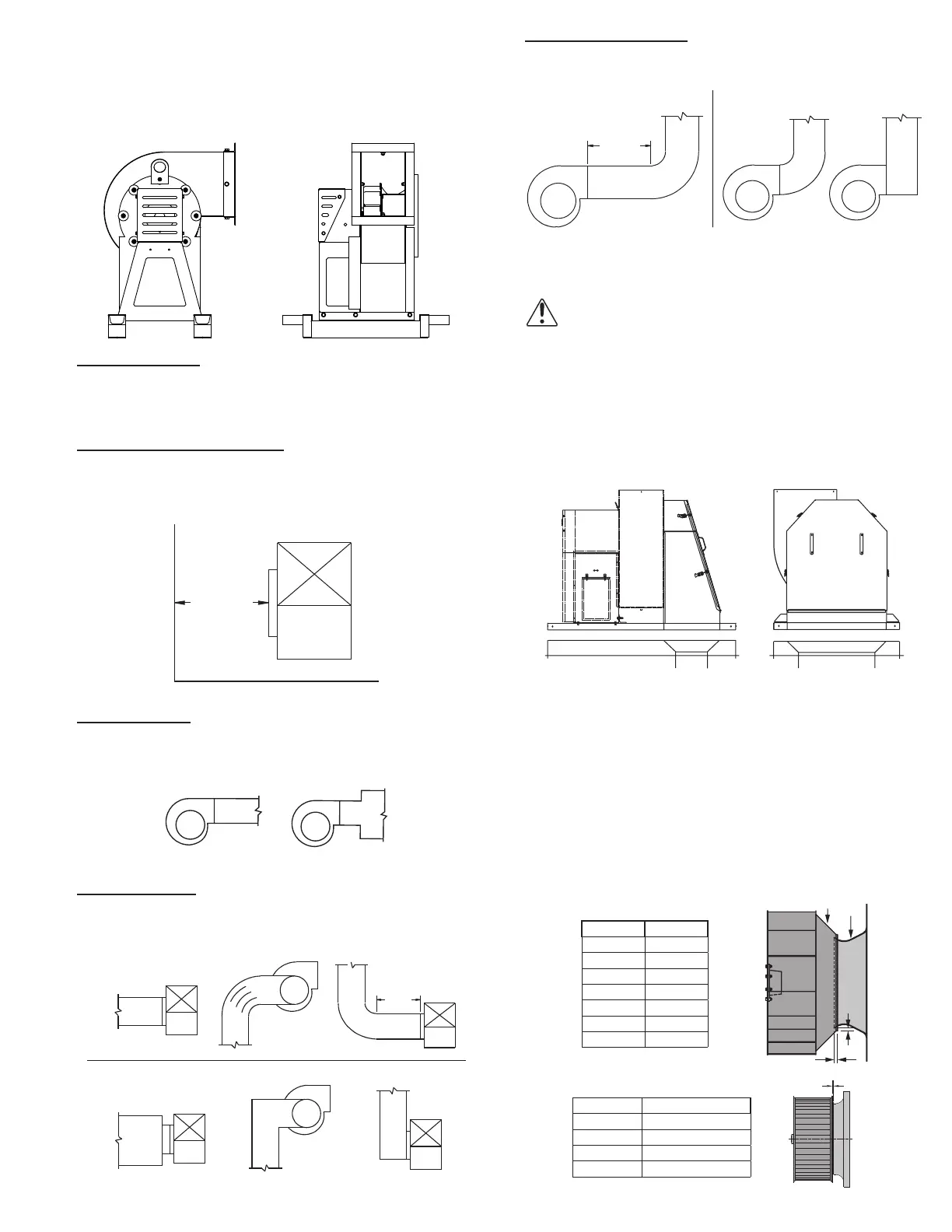

Discharge Duct Turns

Make sure that duct turns located near the fan discharge

curve in the direction of the fan’s rotation.

Discharge Duct Turns

Correct

MIN 3

DIA

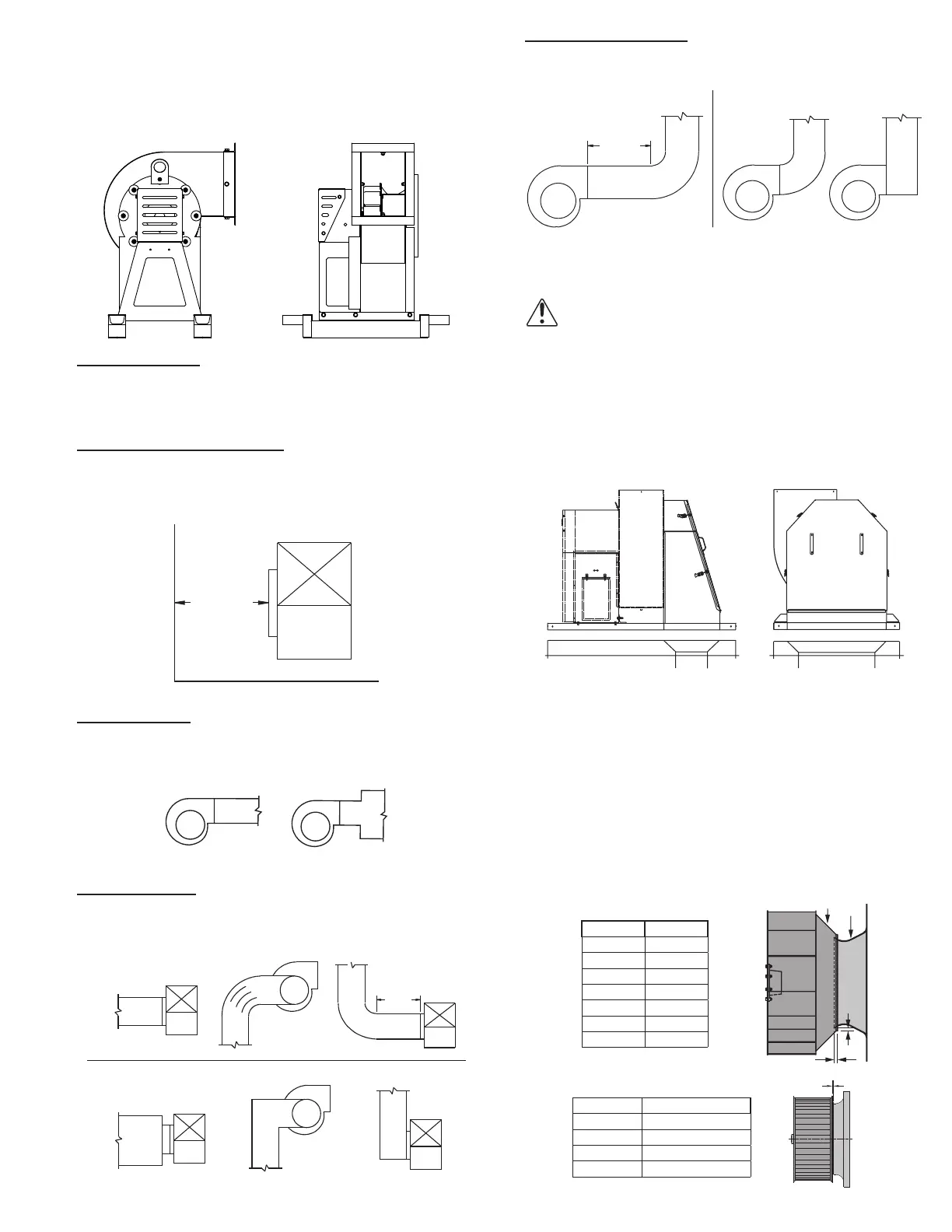

CP with Optional Curb Cap and Inlet Box

NOTICE! UL 762/NFPA96 and local codes may dic-

tate additional or modications to this installation.

The installation diagram below has a solid curb cap

duct adapter placed over the top of the curb. The welded

grease duct with recommended transition is either welded

or sealed with UL recognized re caulk to both the curb

cap duct adapter and the bottom of the fan. A minimum

of two separate outlines of caulk is recommended at the

outer portion of the curb cap duct adapter.

Wheel-to-Inlet Clearance

The correct wheel-to-inlet clearance is critical to proper

fan performance. This clearance should be veried before

initial start-up since rough handling during shipment could

cause a shift in fan components. Refer to the wheel/inlet

drawing for correct overlap.

Adjust the overlap by loosening the wheel hub and mov-

ing the wheel along the shaft to obtain the correct value.

A uniform radial gap (space between the edge of the

cone and the edge of the inlet) is obtained by loosening the

inlet cone bolts and repositioning the inlet cone.

CA, CF and CP

Size Overlap

60–165 3/16”

180–245 1/4”

270–300 5/16”

330–365 3/8”

402 7/16”

445–490 1/2”

540–730 13/16”

RADIAL

CLEARANCE

INLET

CPFD, CPFB

Size Gap/Clearance

100 - 150 1/4

180 3/16

220 1/2

250 - 300 3/4

3. Position isolators under fan (or isolation base/rails)

and secure bolts.

4. Remove blocks and allow fan to rest on oor. Isolators

must be installed on a level surface (leveling should

not be required).

5. Secure isolators to mounting surface.

Duct Installation

Ecient fan performance relies on the proper installa-

tion of inlet and discharge ducts. Be sure your fan con-

forms to the guidelines below.

Non-Ducted Inlet Clearance

If your fan has an open inlet (no duct work), the fan must

be placed 1 fan wheel diameter away from walls and bulk-

heads. An inlet bell should be used in this case.

Non-Ducted Inlet Clearance

MIN 1 DIA

Free Discharge

Avoid a free discharge into the plenum. This will result in

lost eciency because it doesn’t allow for a static regain.

Correct

Incorrect

Free Discharge

Inlet Duct Turns

For ducted inlets, allow at least 3 fan wheel diameters

between duct turns or elbows and the fan inlet.

Incorrect

MIN 3

DIA

Loading...

Loading...