7CA/CF/CP IO&M B51181-002

Motor Bearings

Motors are provided with prelubricated bearings. Any lubrica-

tion instructions shown on the motor nameplate supersede in-

structions below. Motor bearings without provisions for relubri-

cation will operate up to 10 years under normal conditions with

no maintenance. In severe applications, high temperatures or

excessive contaminates, it is advisable to have the maintenance

department disassemble and lubricate the bearings after three

years of operation to prevent interruption of service.

For motors with provisions for relubrication, follow intervals of

the table below.

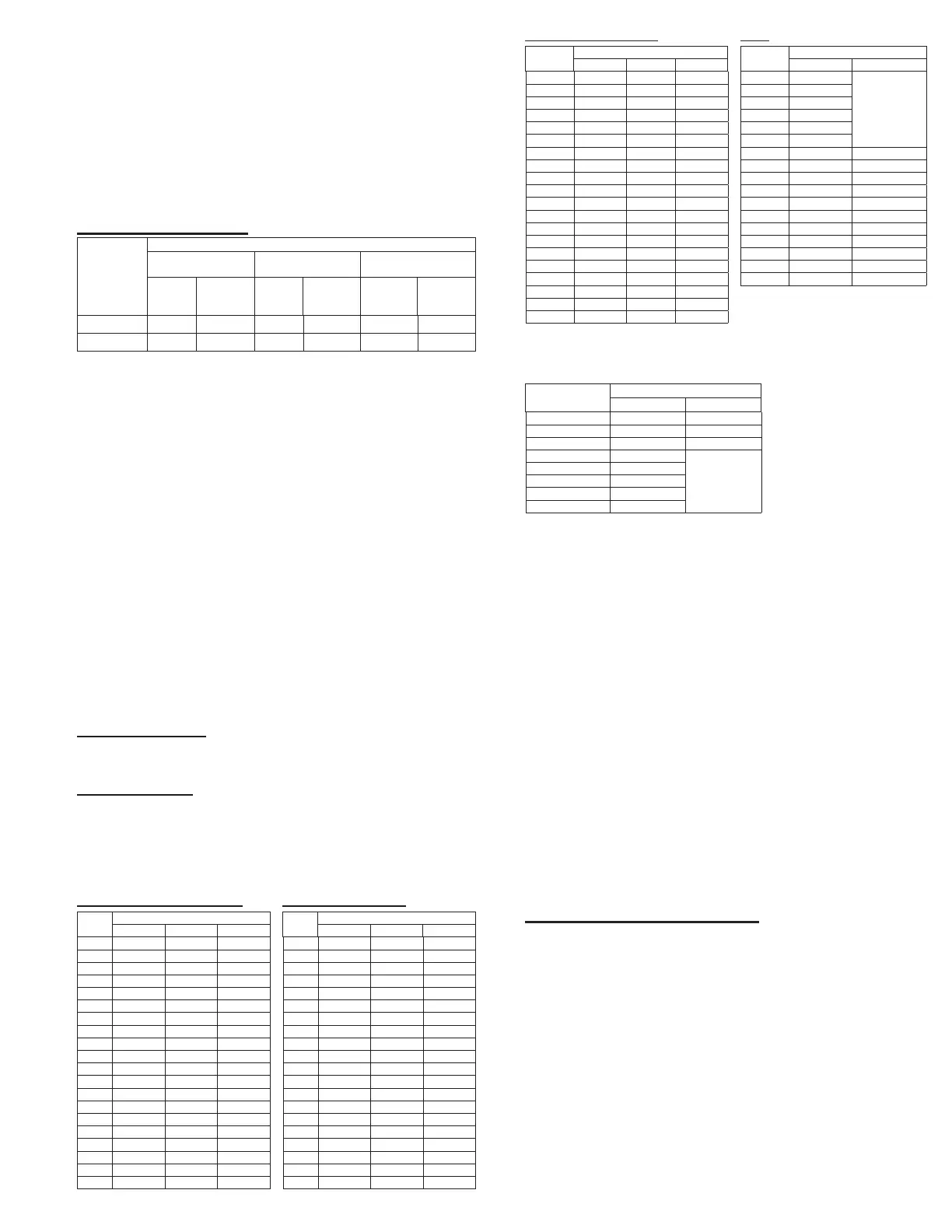

Relubrication Intervals

Service

Conditions

Nema Frame Size

Up to and

Including 184T

213T-365T 404T and Larger

1800

RPM &

Less

Over

1800

RPM

1800

RPM &

Less

Over

1800

RPM

1800

RPM &

Less

Over

1800

RPM

Standard 3 yrs. 6 months 2 yrs. 6 months 1 yr. 3 months

Severe 1 yr. 3 months 1 yr. 3 months 6 months 1 month

Motors are provided with a polyurea mineral oil NGLI #2 grease.

All additions to the motor bearings are to be with a compatible

grease such as Exxon Mobil Polyrex EM and Chevron SRI.

The above intervals should be reduced to half for vertical shaft

installations.

Motor Services

Should the motor prove defective within a one-year pe-

riod, contact your local Loren Cook representative or your

nearest authorized electric motor service representative.

Changing Shaft Speed

All belt driven fans with motors up to and including 5HP

(184T max) are equipped with variable pitch pulleys. To

change the fan speed, perform the following:

1. Loosen setscrew on driver (motor) pulley and remove key,

if equipped.

2. Turn the pulley rim to open or close the groove facing. If

the pulley has multiple grooves, all must be adjusted to the

same width.

3. After adjustment, inspect for proper belt tension.

Speed Reduction

Open the pulley in order that the belt rides deeper in the

groove (smaller pitch diameter).

Speed Increase

Close the pulley in order that the belt rides higher in the

groove (larger pitch diameter). Ensure that the RPM lim-

its of the fan and the horsepower limits of the motor are

maintained.

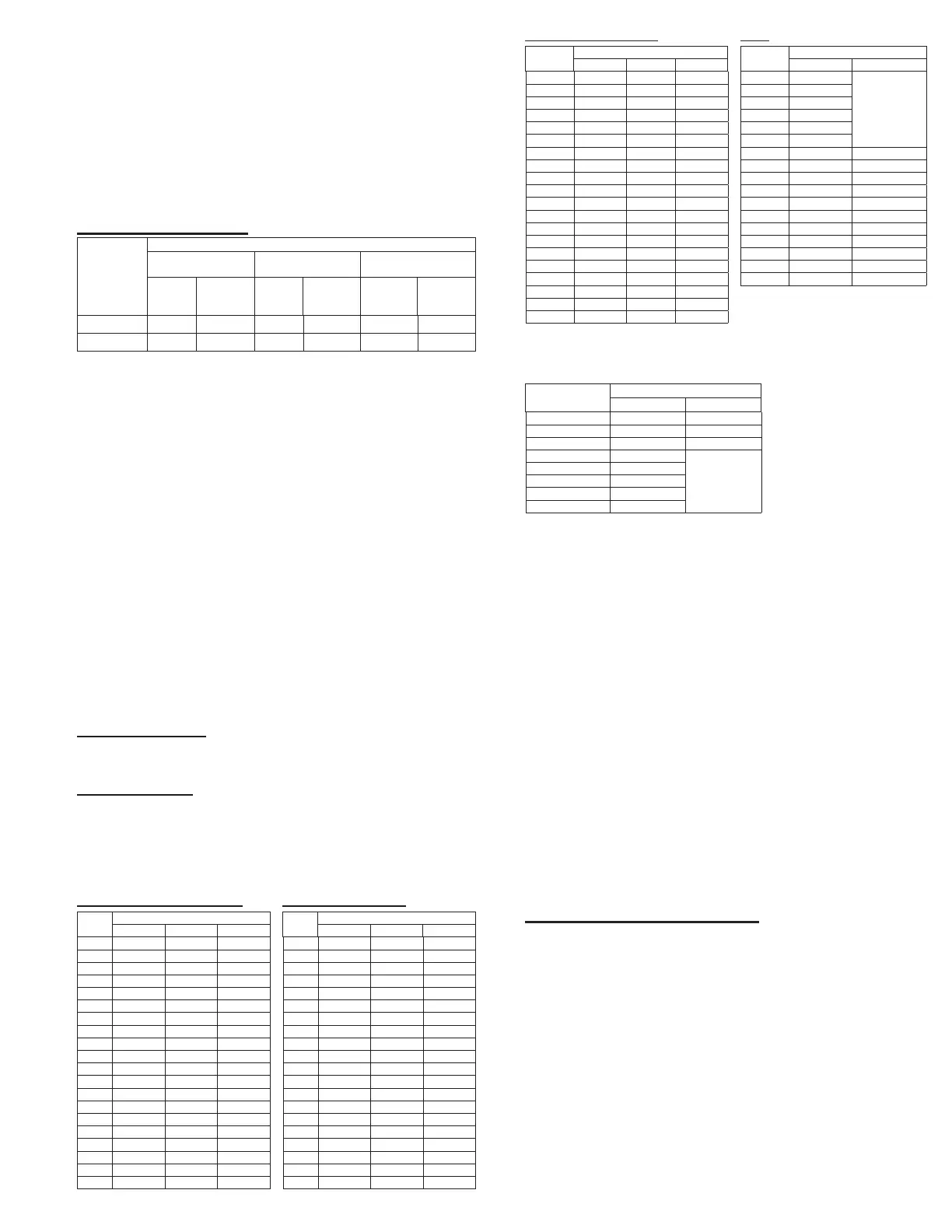

Maximum RPM

CA SWSI, CPS-A, CPA-A

Size

Max. RPM

Class I Class II Class III

120 3348 4368 5503

135 2976 3883 4892

150 2678 3494 4403

165 2435 3177 4002

180 2114 2757 3474

195 1951 2545 3207

210 1812 2363 2978

225 1691 2206 2779

245 1553 2026 2553

270 1419 1851 2332

300 1277 1666 2099

330 1161 1514 1908

365 1064 1388 1749

402 965 1259 1586

445 873 1138 1434

490 793 1034 1303

540 719 938 1182

600 647 844 1094

660 588 768 967

730 532 694 874

CA and CAF DWDI

Size

Max. RPM

Class I Class II Class III

120 3714 4846 6105

135 3307 4315 5436

150 2575 3357 4230

165 2374 3095 3901

180 2176 2839 3577

195 2009 2621 3302

210 1865 2434 3066

225 1741 2271 2862

245 1631 2128 2681

270 1443 1883 2372

300 1262 1647 2074

330 1147 1496 1885

365 1038 1354 1706

402 941 1228 1547

445 851 1110 1399

490 773 1009 1271

540 702 916 116 4

600 631 823 1037

660 574 749 944

730 519 677 853

CF SWSI, CPS, CPA

Size

Max. RPM

Class I Class II Class III

60-100* 4230 5519 6953

120 3404 4441 5595

135 3026 3948 4974

150 2723 3553 4476

165 2476 3230 4069

180 2269 2961 3730

195 2095 2733 3443

210 1795 2341 2950

225 1675 2185 2753

245 1539 2007 2529

300 1257 1639 2065

330 1142 1490 1877

365 1023 1334 1681

402 939 1225 1543

445 849 110 8 1396

490 771 1006 1268

540 700 913 115 0

600 630 822 1035

660 573 747 9 41

730 518 675 851

*Sizes 60 through 100 only applies to

CPS and CPA.

CPV

Size

Max. RPM

Standard Reinforced

60-100* 2719

-

120 2527

135 2093

150 2035

165 1766

180 1588

195 1429 1571

210 1277 1407

225 1152 1265

245 1015 1260

270 876 1091

300 837 1006

330 716 869

365 624 805

402 539 701

445 463 660

490 360 576

RPM Derating Factor

Temperature

(°F)

RPM Factor

Steel Aluminum

70 1.00 1.00

200 0.98 0.93

300 0.96 0.79

400 0.94

**

500 0.91

600 0.87

700 0.81

800 0.75

For elevated airstream temperatures, the maximum fan speed limits

must be derated by the factors above.

Pulley and Belt Replacement

1. Remove pulleys from their respective shafts.

2. Clean the motor and fan shafts.

3. Clean bores of pulleys and coat the bores with heavy oil.

4. Remove grease, rust or burrs from the pulleys and

shafts.

5. Remove burrs from shaft by sanding.

6. Place fan pulley on fan shaft and motor pulley on its

shaft. Damage to the pulleys can occur when exces-

sive force is used in placing the pulleys on their re-

spective shafts.

7. Tighten in place.

8. Install belts on pulleys and align as described in Belt

and Pulley Installation.

Bearing Replacement

The fan bearings are pillow block ball bearings.

An emery cloth or le may be needed to remove imper-

fections in the shaft left by the setscrews.

For Arrangement 1, 2, 9 and 10:

1. Mark the position on the shaft of both bearing races, set-

screws, and the wheel and pulley. Mark the location and

orientation of the inlet cone. Note the clearance between

the wheel and inlet cone.

2. Remove the fan pulley and inlet cone.

3. Remove the wheel from the shaft. A 2-jaw puller may be

needed.

4. Remove bearing hold-down bolts. Remove shaft and

bearings as one unit.

5. Remove the anti-corrosion coating from the shaft with a

suitable degreaser.

6. Remove the bearing from the shaft using a bearing pull-

er. If a bearing puller is not available, tap on the bearing

with a wood block and hammer to remove it.

7. Smooth and clean the shaft and bearing bore thoroughly.

**Aluminum wheels are

not available above 300°.

Loading...

Loading...