Owner’s Manual

Page - 9 - of 22

Organics: Coolerado’s HMX plate material is manufactured with polypropylene that is not a food source for molds; the plate

material also has a biocide impregnated into it to prevent organics from growing. Typically the biocide supplied from a potable water

supply district will be enough to prevent any mold growth. However, if supply water that does not contain biocides is being used,

like well water, both the air and maybe the water will have organics that can sustain molds, generally in the form of a slime that can

grow in the water distribution system and on the wet portion of the HMX plate surface. In these cases a biocide such as chlorine may

be required.

Temperature: When water is heated dissolved minerals like calcium will come out of solution and form scale; the reason hot water

heaters and pipes build up scale. For this reason we recommend water supply pipes to the Coolerado units be kept in cool places or

insulated when exposed to the sun.

Dissolved minerals: There are a lot of dissolved minerals in water, however we are most concerned with the hardness of water

made up mostly of calcium but can include magnesium. Hard water causes two problems. First, it prevents soap from creating suds

and leaves soap scum on sinks, etc. The second, and maybe the bigger problem for any evaporative equipment, is the formation of

scaling most generally in the form of calcium carbonate; the magnesium will stay in solution under much higher concentrations.

Calcium carbonate can close off water lines, collapse cooling towers from the weight of scale build up and in general cause many

problems. The key here is the amount of calcium water hardness. In low quantities of hard water is not a problem.

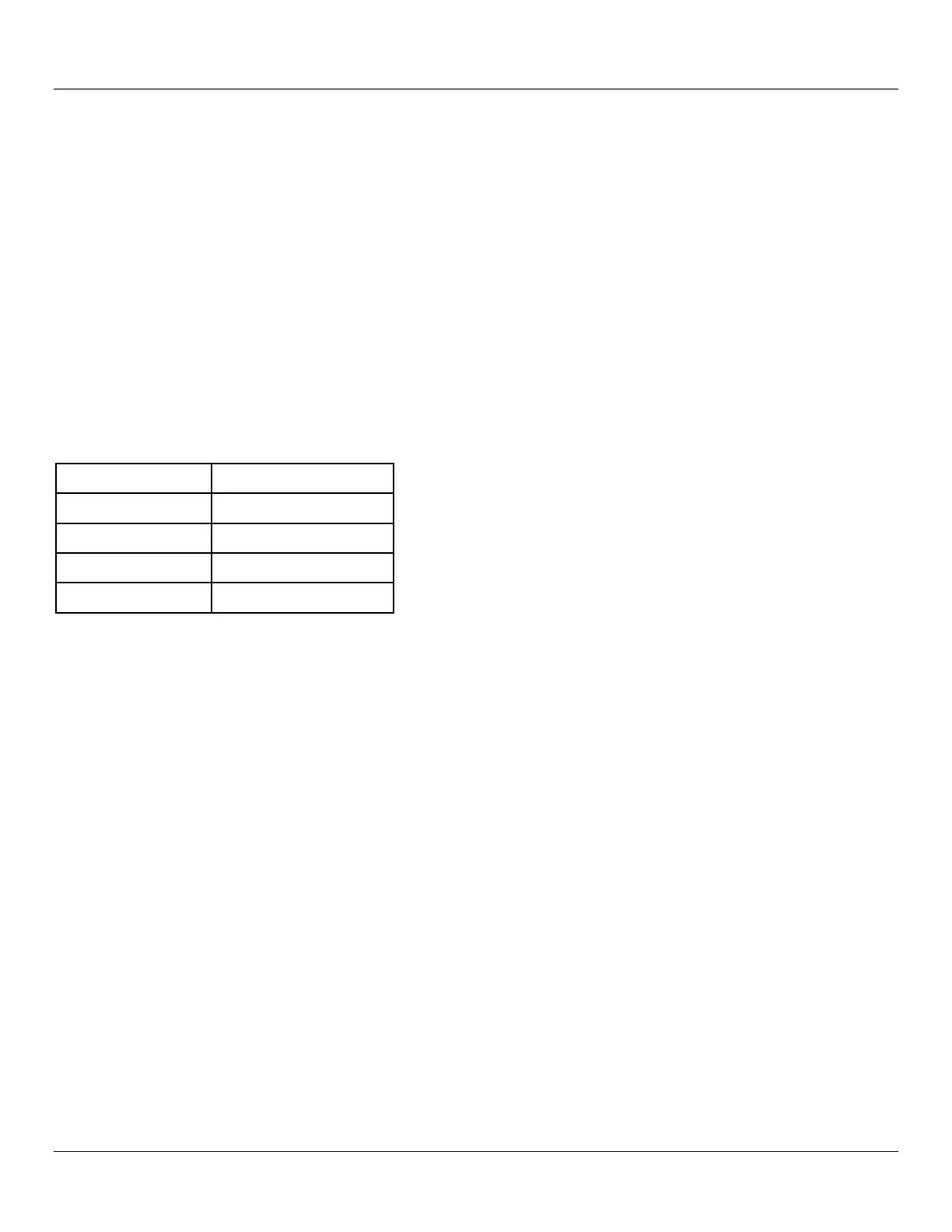

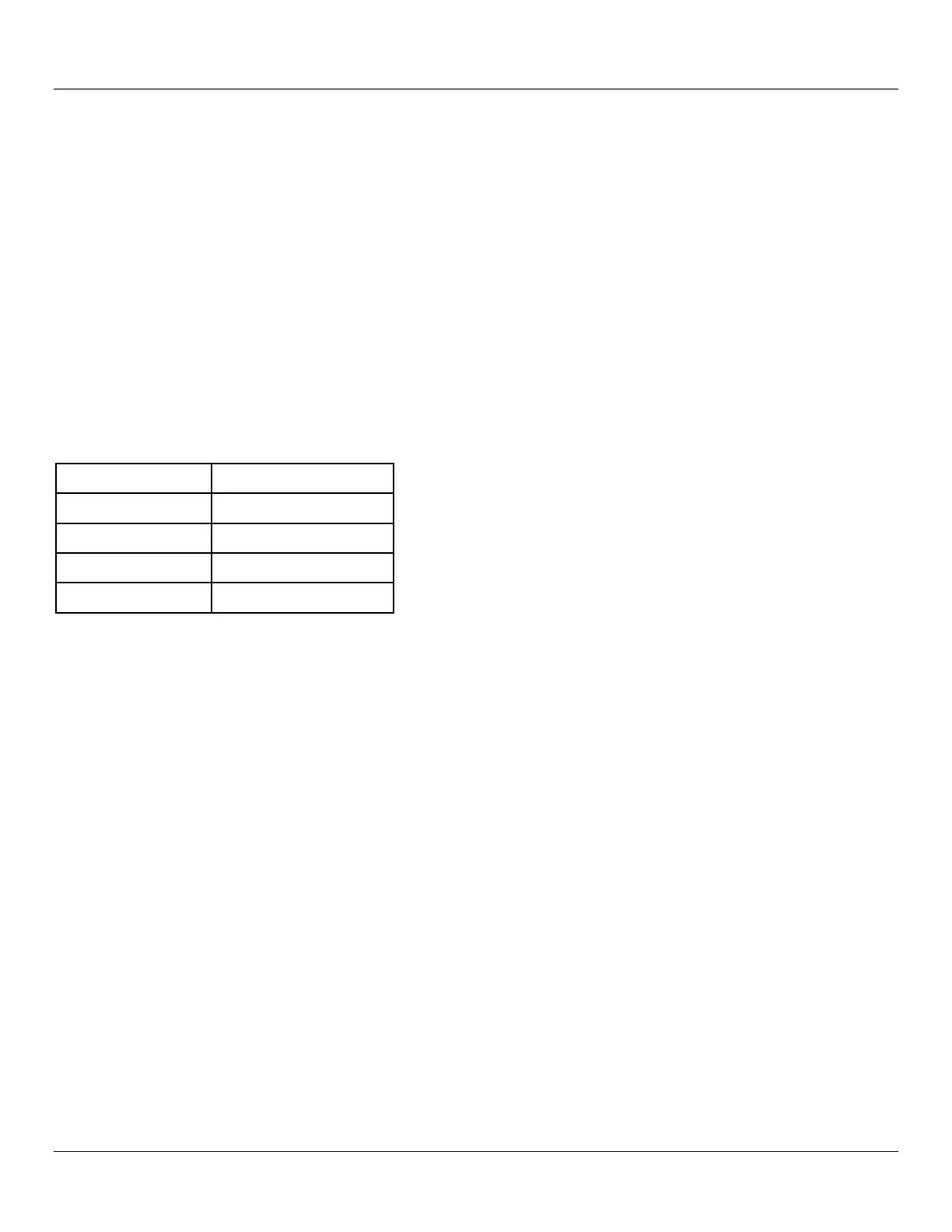

How hard water is generally defined as:

Water that is Moderately Hard or greater should be treated with a sodium-based water softener.

Coolerado cannot know the details of your water supply and therefore how the water will react with our water delivery system.

The water should be tested to properly address any water quality concerns, contact your local water utility to determine the total

harness of your water or have the water tested at a water laboratory.

Heat Exchangers:

Each heat exchanger should be visually inspected when the air filters are replaced. If any debris is found it should be removed. If the

heat exchangers appear to be damaged in any way contact your local representative. At the end of the cooling season, after the heat

exchangers are dried out, the exhaust sides of the exchanger can be inspected for mineral buildup. A hard crust of minerals indicates

excessive mineral buildup. If a water softener is not installed it may be needed.

Air Filters:

The C60 requires four 2” x 20” x 25” (50 mm x 500 mm x 625 mm) pleated MERV 8 filters.

The M50A requires three 2” x 20” x 25” (50 mm x 500 mm x 625 mm) pleated MERV 8 filters.

The M30 requires two 2” x 20” x 25” (50 mm x 500 mm x 625 mm) pleated MERV 8 filters.

One 1” (25 mm) thick filter can be used in place of a 2”/50 mm filters.

Caution: Do not use two 1” (25 mm) filters in series as the pressure drop will be too high, see Figure 4.

The filters should be changed regularly to ensure proper airflow through the system. If the system is located in an area where there

are higher levels of airborne debris such as pollen, leaves, dust or insects, in which case the filters should be inspected more often.

Inspect the filters periodically during the cooling season and replace with new filters as required.

Loading...

Loading...