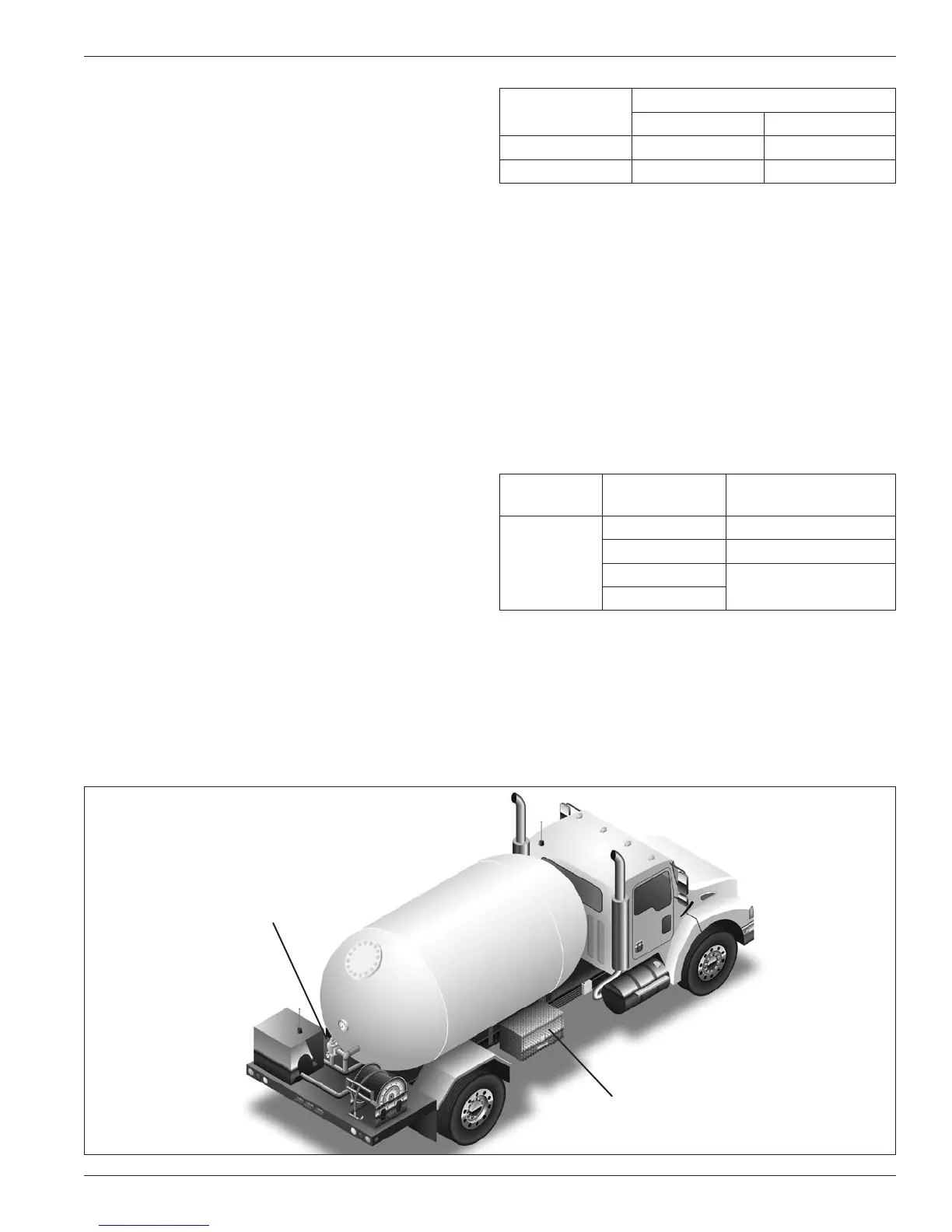

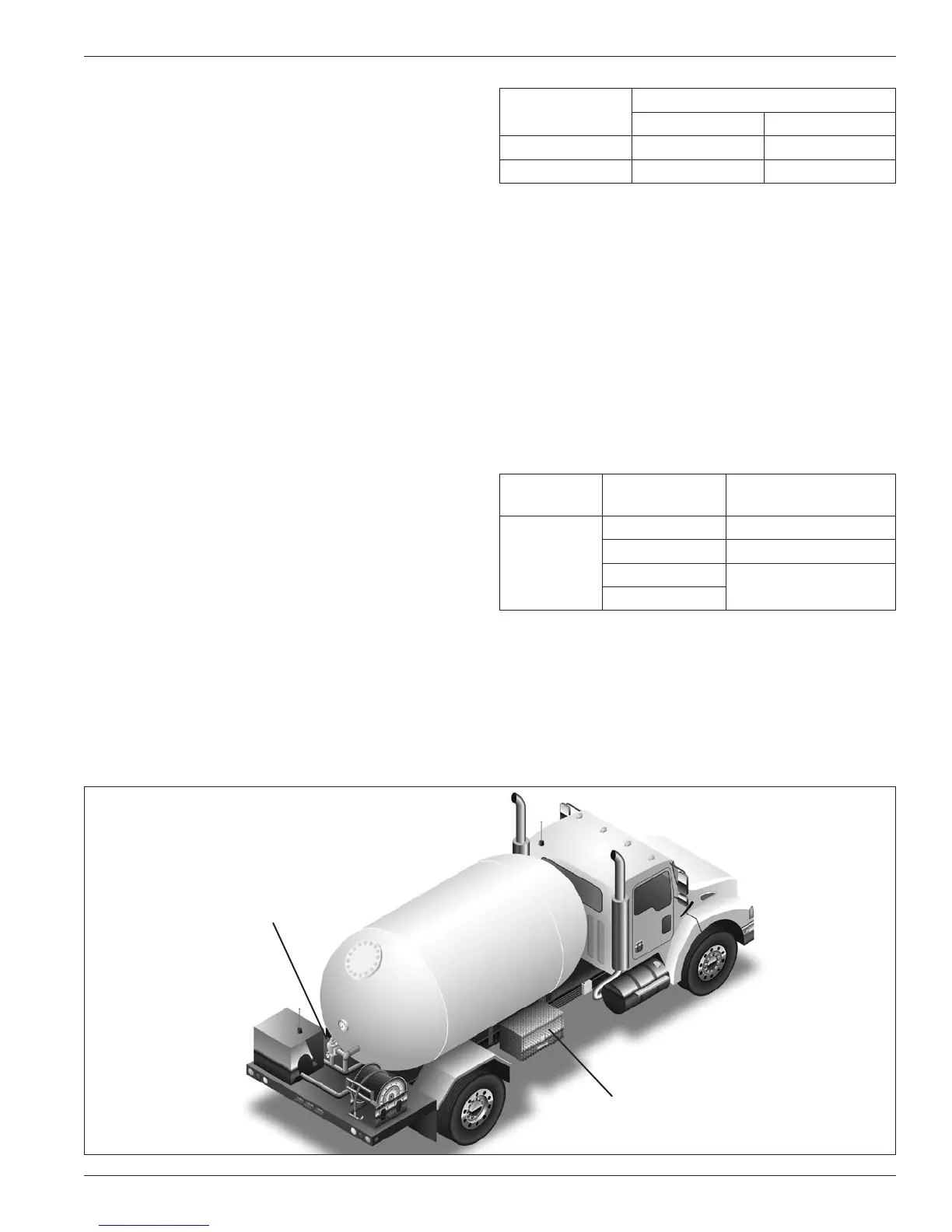

Figure 2.1: Typical installation.

Features of the T166 Automatic

External Bypass Valve

The CORKEN T166 external bypass valve is designed

for use with truck pumps. It controls the pump

discharge pressure and bypasses excess liquid back

to the truck tank.

This bypass valve can also be used in stationary

applications utilizing sliding vane pumps.

Chapter 2—Installation of the T166

Automatic External Bypass Valve

Proper installation ensures optimum performance of the

pump and external bypass valve. Install the T166 external

bypass valve on the discharge side of the pump in either

a vertical or horizontal position. The discharge piping of

the bypass valve typically connects to the vapor section

of the truck tank using a back check valve. A typical truck

installation is shown in Figure 2.1. The recommended

pipe size for the discharge line is given in the table below.

For distances of 50 feet or more, the next larger pipe size

should be used.

Stationary applications with internal relief valves:

When the T166 external bypass valve is used for vapor

venting, the piping should be the same size used with the

B166 external bypass valve.

To ensure optimum performance of the external bypass

valve and the entire pumping system, follow the instructions

in this manual.

Pipe Size for the Discharge Line

Flow Rate

Pipe Size by Model Number

T166-1.25 T166-1.5

Up to 80 GPM 1-1/4" —

Up to 100 GPM — 1-1/2"

2.1 Operation of the T166

Automatic External Bypass Valve

Truck Applications:

The differential pressure setting of the B166 external bypass

valve is adjustable. The range of differential pressure

depends on the size of the spring installed in the bypass

valve. When the bypass valve ships from the CORKEN

factory, a tag identifying the spring size is attached to the

valve bonnet. The table below shows the part number

and differential pressure range for each spring. All of the

springs are interchangeable with each valve size.

Valve Model Spring Number

Differential Pressure

(PSIG)

T166

113 8 25–60

1193 50–150

1193

100–225

1313

1. Install liquid-filled pressure gauges equipped with a

needle valve or snubber in the following locations:

a. Pump discharge gauge port or Inlet side of the

bypass valve.

b. Supply tank and/or pump suction.

Bypass Valve

Pump

7

Loading...

Loading...