Supersedes 3200-625

June, 2018 Dec, 2020

Cornell Pump Company

Run-Dry Seal Instructions and Parts Page

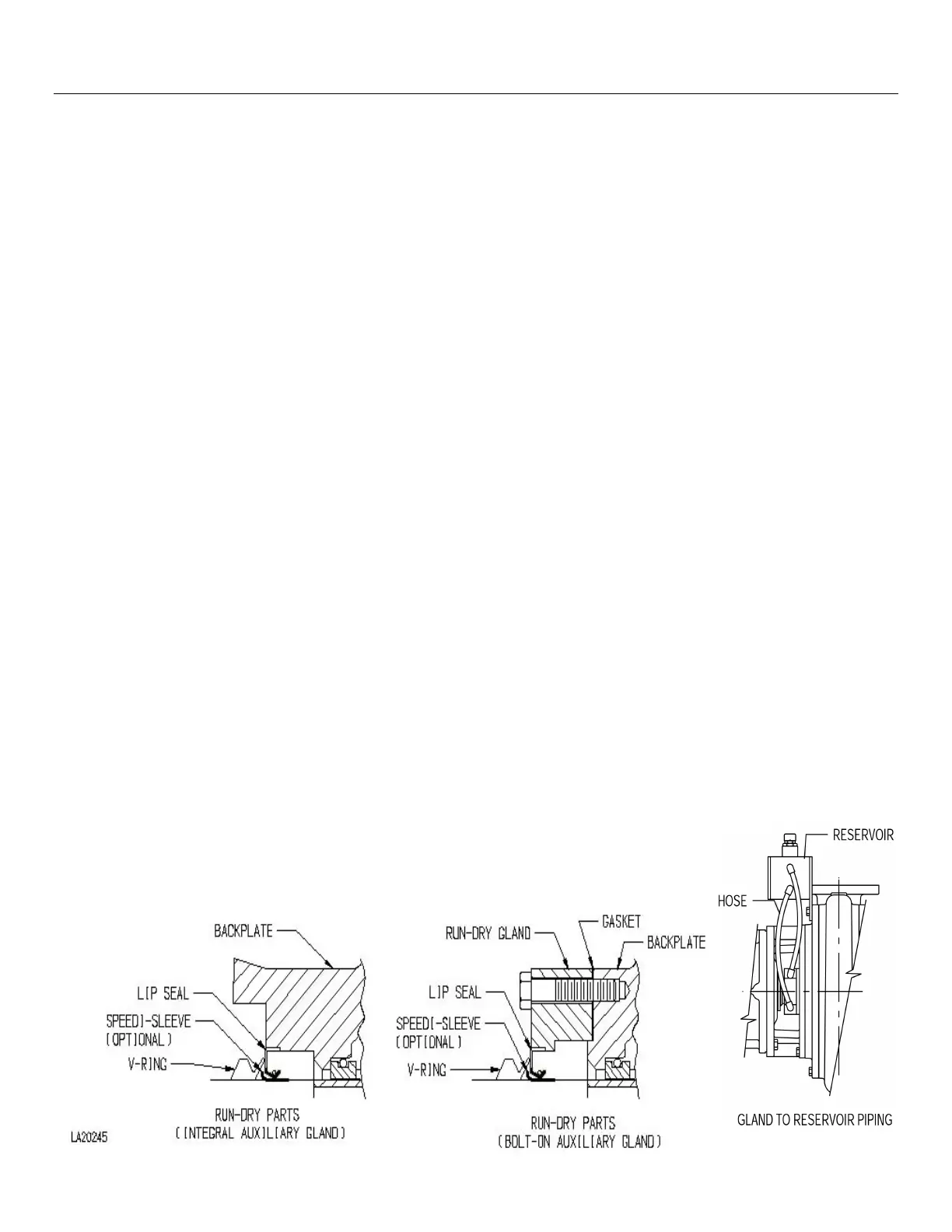

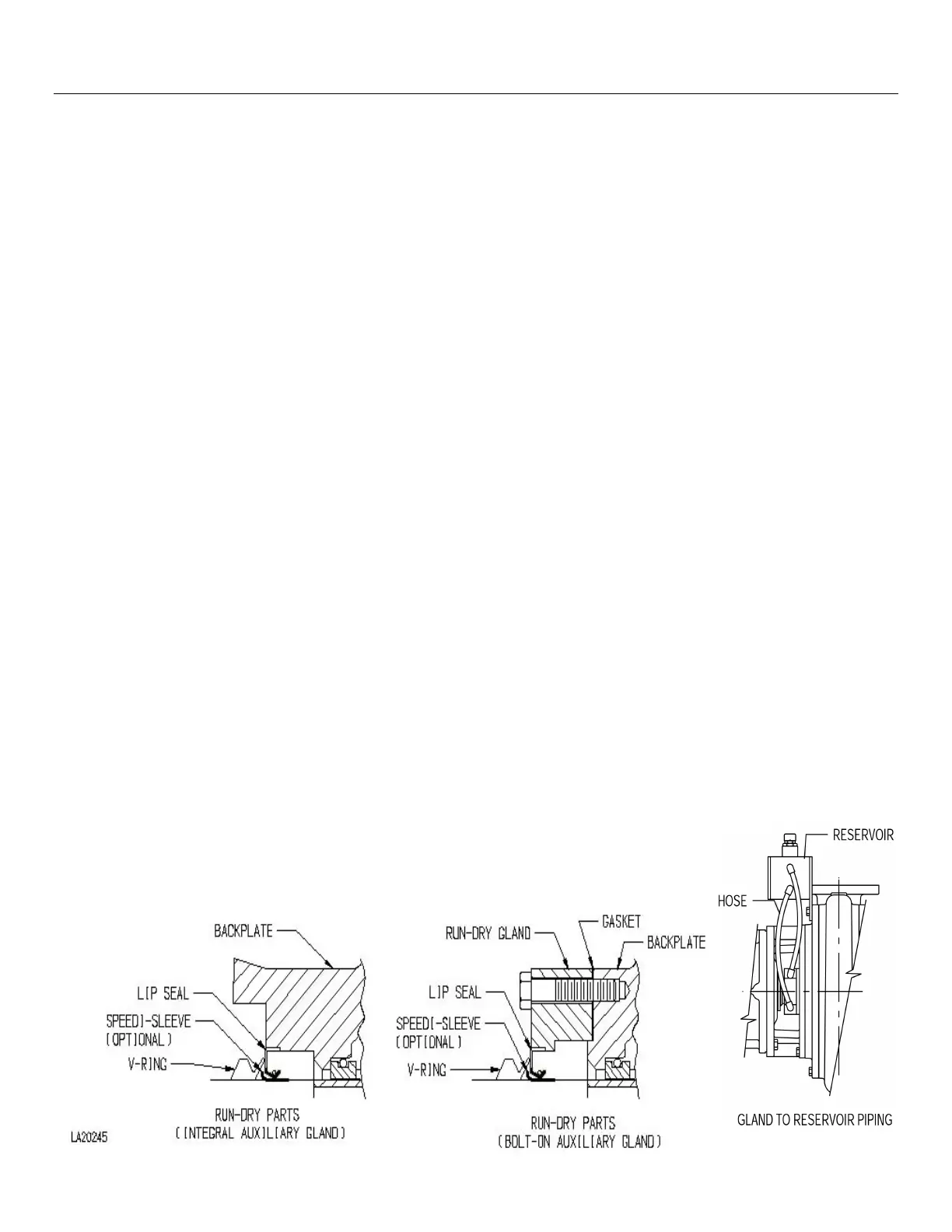

Pumps equipped with Cornell’s patented Cycloseal

®

(patent # 5,489,187) system have an optional run-dry

feature. The run-dry feature employs an auxiliary gland and reservoir mounted to the backplate. The rotation

of the drive shaft circulates lubricant from the reservoir to the gland, then back to the reservoir. The lubricant

serves to cool the seal faces even when there is no liquid in the pump casing. A V-ring may be installed when

space allows.

THE RUN-DRY RESERVOIR LUBRICANT LEVEL SHOULD BE MAINTAINED WITHIN THE RANGE

SHOWN ON THE PLASTIC RESERVOIR OR TO THE TOP SIGHT GLASS OF THE METAL

RESERVOIR; however, lubricant will circulate as long as the lubricant level is above the bottom sight glass.

When filling the reservoir with lubricant, be sure the air has been purged out of the upper circulation hose to

prevent vapor locking.

Fluid changes recommended every 1000 hours or once a year, whichever comes first.

Lubricant can be added either during pump operation or while shutdown.

If water begins to accumulate in the reservoir, or the fluid level depletes rapidly, this may indicate mechanical

seal failure. Leakage of reservoir fluid from the gland would indicate a damaged or worn lip seal.

The optional run-dry feature is used for 2 different applications:

1. Backup Run-Dry Applications

With the backup run-dry feature, the pump can operate for a short period of time with no liquid in the pump

casing without causing damage to the mechanical seal. The run-dry option is not intended for extended periods

of operation without liquid in the pump casing, but rather as a safety feature to save the mechanical seal should

the pump unexpectedly lose prime or inadvertently be started without being primed.

Recommended reservoir lubricants:

The reservoir fluid should be Cornell 60/40 Propylene Glycol Run-Dry fluid with corrosion inhibitor

(p/n:N10263-415) or compatible fluid.

2. Extended Service Run-Dry Applications (Large Capacity Reservoir/Redi-Prime

®

Reservoir)

(NOTE: Internal pump tolerances have been modified for this application refers to BOM).

With the extended service run-dry feature, the pump can operate for several hours with no liquid in the pump

casing without causing damage to the mechanical seal.

Recommended reservoir lubricants:

The reservoir fluid should be Cornell 60/40 Propylene Glycol Run-Dry fluid with

corrosion inhibitor (p/n:N10263-415) or compatible fluid.

Loading...

Loading...