Supersedes 3200-353

March, 1990 Feb., 2005

Cornell Pump Company

Page 1 of 2

Pressure Testing

CAUTION: DO NOT OPERATE PUMP WHEN AT TEST PRESSURE

WARNING: Failure to follow instructions may damage pump and/or result in serious personal injury.

MAXIMUM TEST PRESSURE

Maximum test pressure should not exceed 125% of shutoff pressure or 150% of design pressure, whichever is

greater. Refer to Cornell Catalog for operating pressure limits of your pump. If your calculated test pressure is

above these limits, consult factory prior to proceeding.

TEST FLUID

Liquid may be pumpage or water or any liquid compatible with pump materials.

For pumps equipped with packing: WARNING: Do not use compressed air to pressure test pump.

a. Fill pump gradually with liquid by gravity flow (10 PSI max. pressure).

b. Vent air from volute and close vent valve.

c. Raise pressure gradually to required test pressure. See “Maximum Test Pressure.”

d. Allow packing to leak freely (special protection of motor may be necessary).

e. If packing is tightened to reduce leakage, lubricant may be squeezed out of packing. Loss of packing

lubricant may require replacement of the packing.

FOR PUMPS EQUIPPED WITH SINGLE SEAL:

CAUTION: DO NOT RUN SEAL DRY – SEE SEAL INSTRUCTIONS

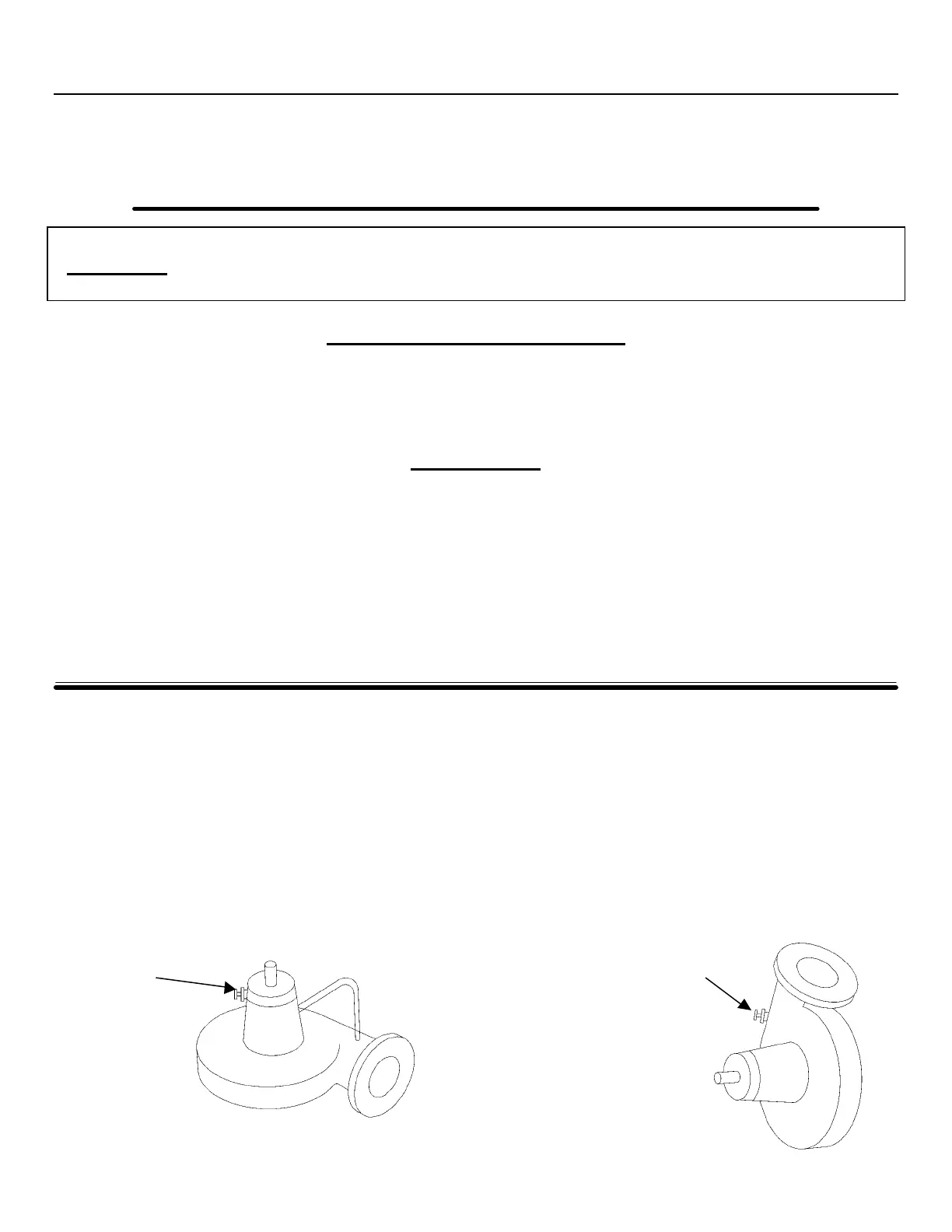

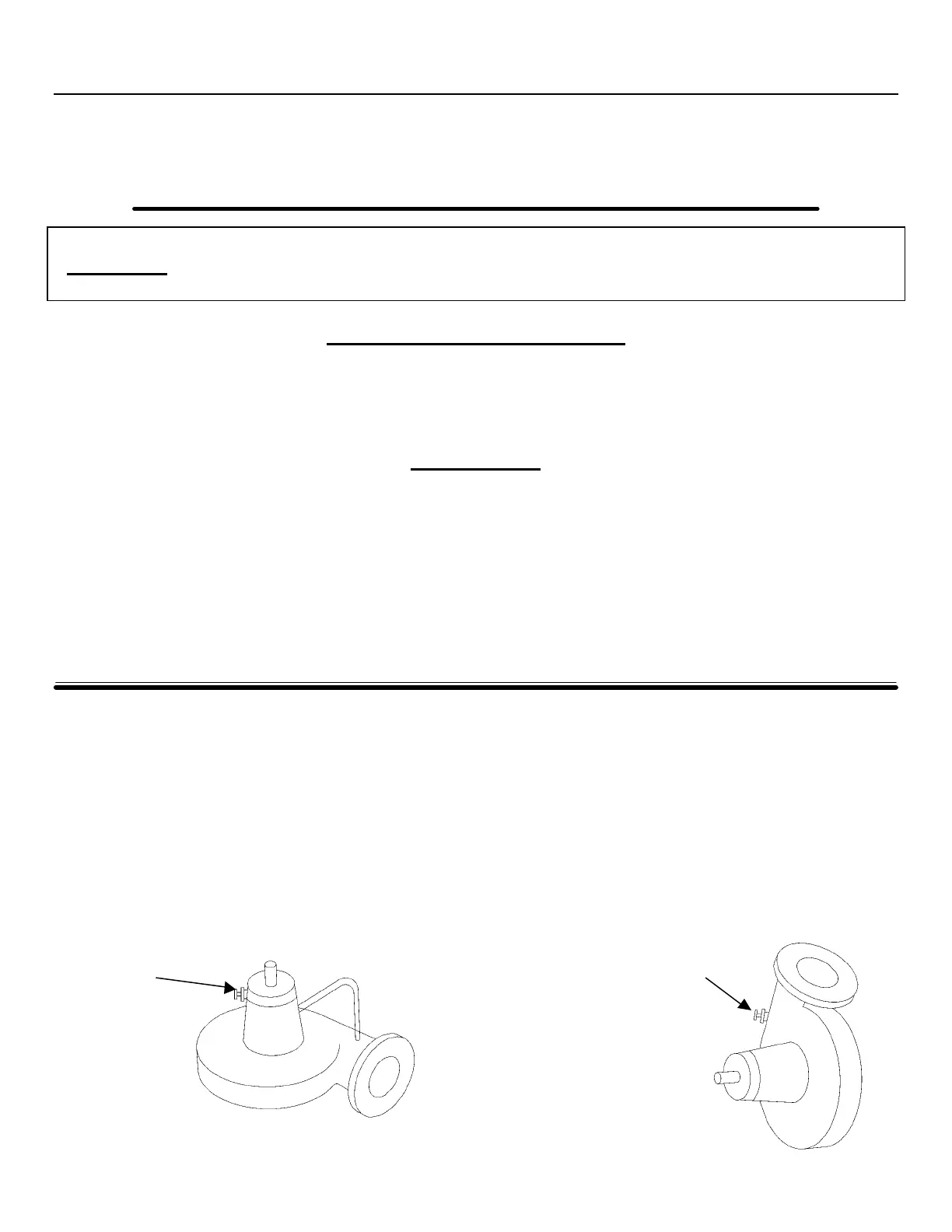

a. Open vent valves on volute or seal gland if shaft vertical (the seal gland in a horizontal pump will not have a

vent valve).

b. Fill pump gradually with liquid by gravity flow (10 PSI max. pressure).

c. Vent air from volute and close vent valve.

d. Vent air from seal gland (If shaft vertical) and close vent valve.

e. Raise pressure gradually to required test pressure. See “Maximum Test Pressure.”

PRESSURE TESTING

GLAND

VENT ON VOLUTE

Loading...

Loading...