Supersedes 3200-353

March, 1990 Feb., 2005

Cornell Pump Company

Page 2 of 2

CAUTION: DO NOT OPERATE PUMP WHEN AT TEST PRESSURE

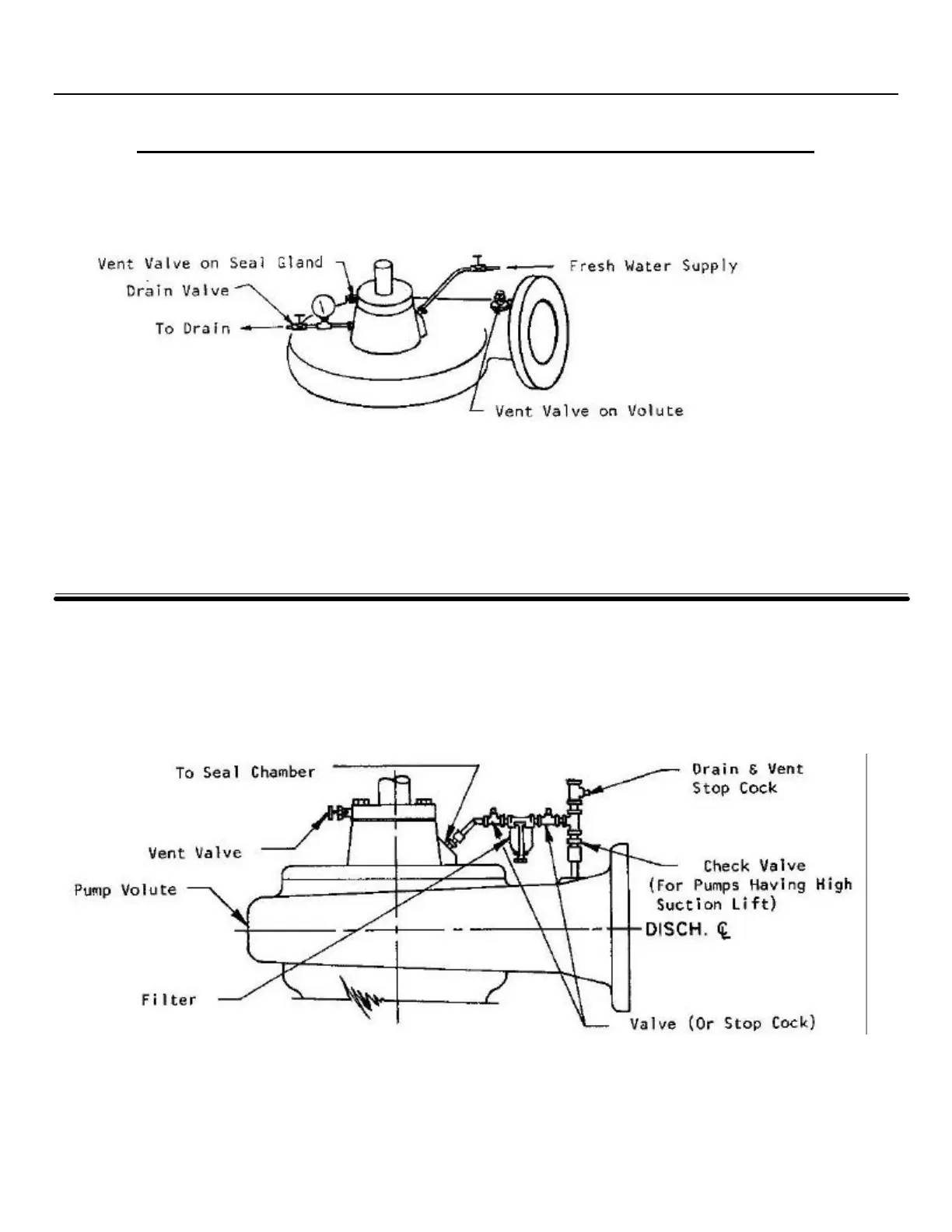

FOR PUMPS EQUIPPED WITH DOUBLE SEAL, OUTSIDE SEAL WATER SUPPLY.

CAUTION: DO NOT RUN SEAL DRY – SEE SEAL INSTRUCTIONS

A. Turn on supply water to seal chamber, close drain valve.

B. Open vent valve in seal gland and vent off air.

C. Close vent valve.

D. Raise pressure of supply water to pressure at which hydrostatic testing will be done. If water supply cannot

be raised to required test pressure, close valve in supply line to trap all seal water in seal chamber.

E. Fill pump gradually with liquid by gravity flow (10 PSI max. pressure).

F. Vent air from volute and close vent valve.

G. Raise pressure gradually to required test pressure. See “Maximum Test Pressure.”

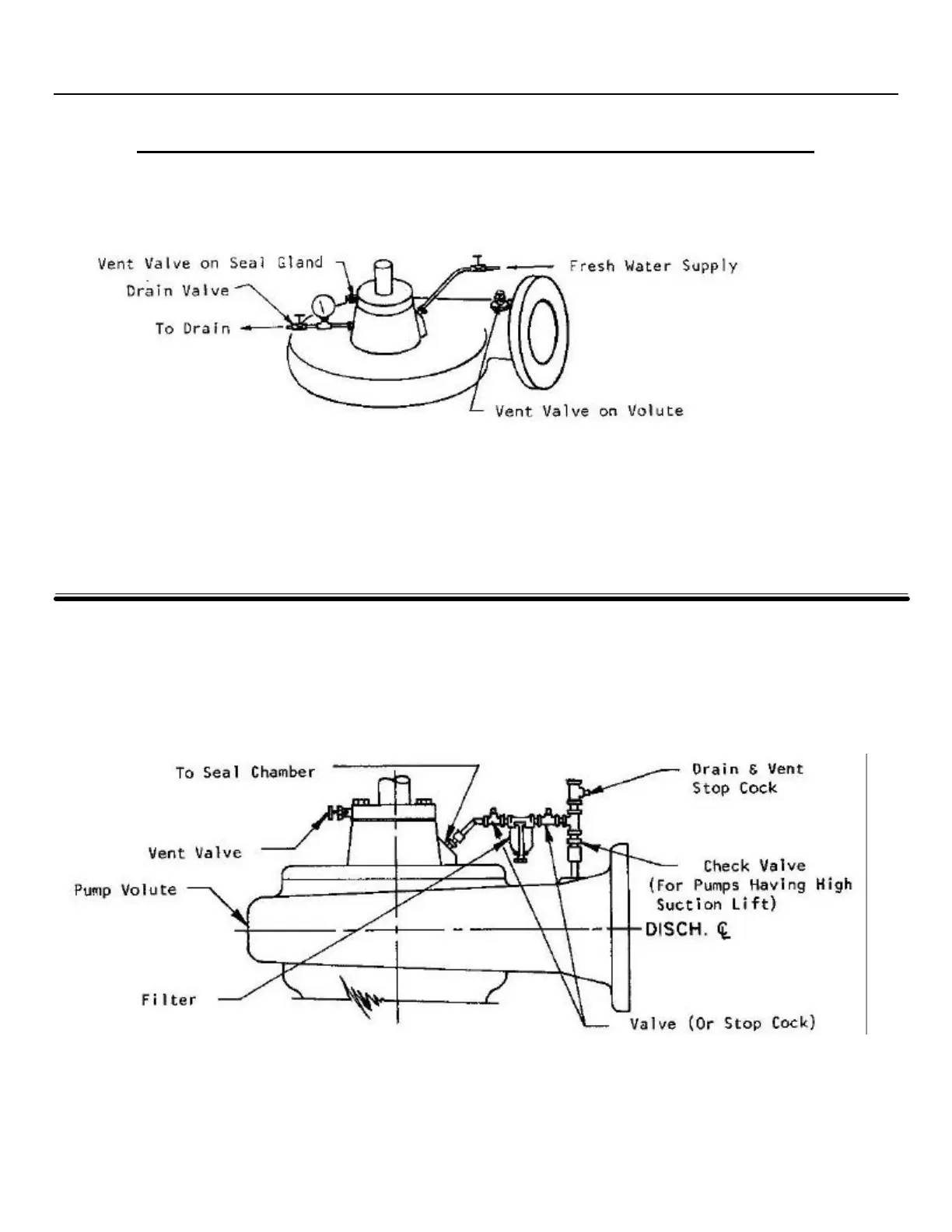

For pumps equipped with double seal, pumpage lubricated (from line containing filter

from volute to seal chamber).

CAUTION: DO NOT RUN SEAL DRY – SEE SEAL INSTRUCTIONS

A. Open vent valve in seal gland and volute. (Horizontal pump has vent valve on volute only).

B. Open valves in line from volute to seal chamber on each side of filter.

C. Fill pump gradually with liquid by gravity flow (10 PSI max. pressure).

D. Vent air from volute and close vent valve.

E. When liquid without bubble is flowing steadily from the vent valve on the seal gland, close vent valve.

F. If filter has glass or plastic bowl and test pressure is over 50 PSI, close valves on both sides of filter.

G. Raise pressure gradually to required test pressure. See “Maximum Test Pressure.”

Loading...

Loading...