New 3200-992

February, 2011

Cornell Pump Company

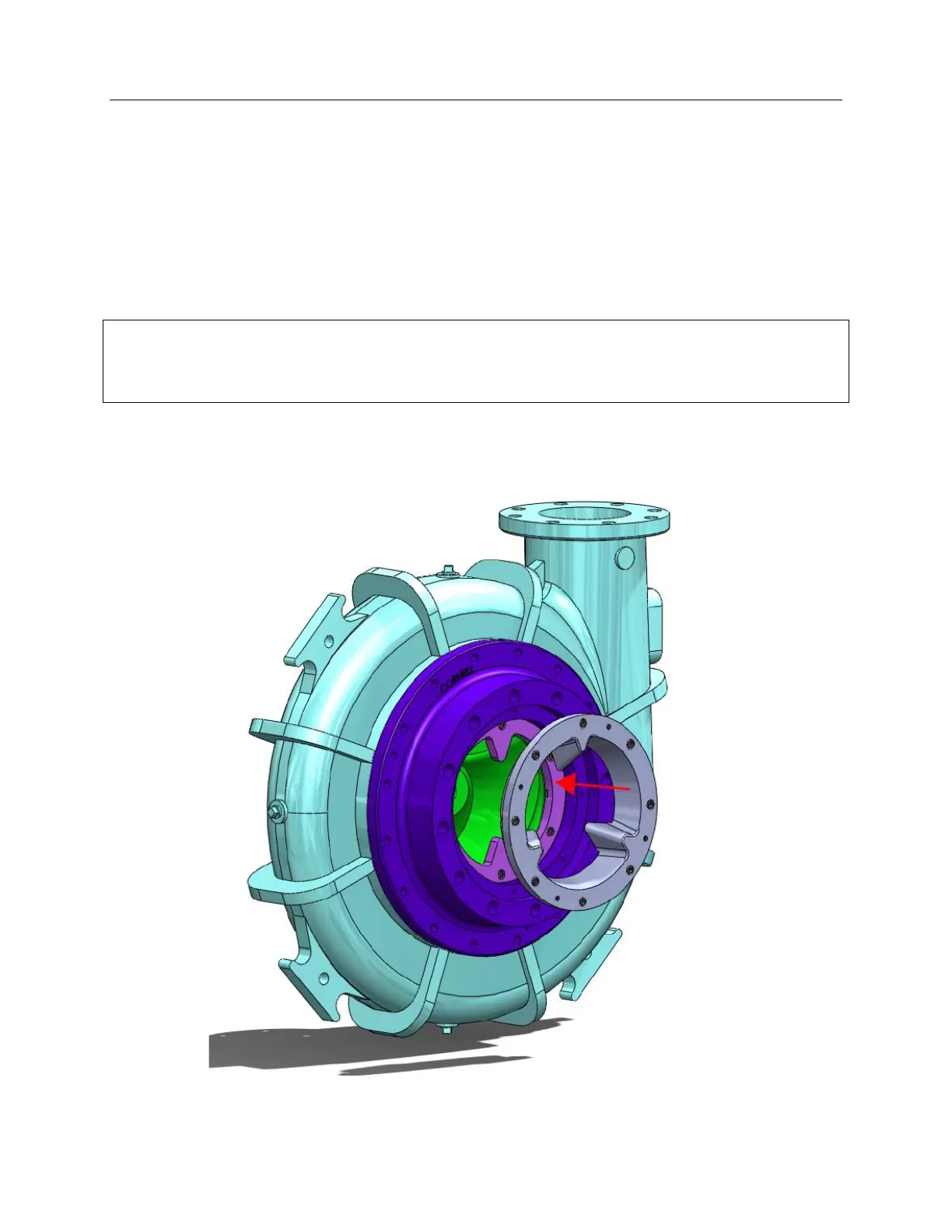

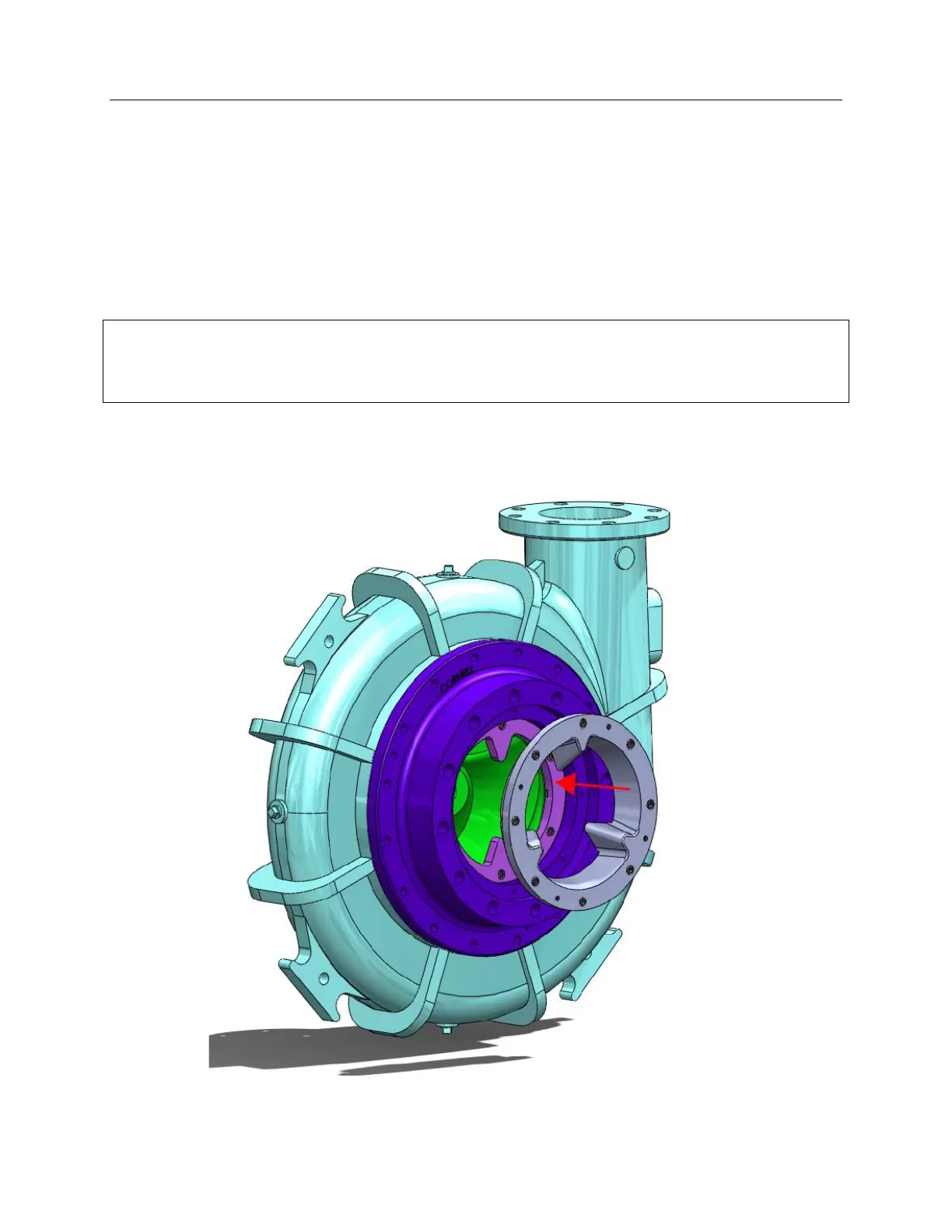

Register stationary cutter plate (392B) to volute casing (2) and suction cover (1) (if applicable) till

the stationary cutter plate bottoms out on rotating cutter ring (392A) Figure 7. Evenly adjust set screws

to a .010” to .020” clearance (Each 1/4 turn of set screw is approximately .010” of adjustment) Figure 8.

Initially start with a quarter turn of each set screw and then check clearances. Loosely tighten stationary

cutter plate to volute and/or suction cover with cap screws. Evenly torque cap screws to recommended

20ft-lb. Re-check cutter clearance and adjust set screws and cap screws as necessary to achieve

clearances. Check for rubbing of assembly by rotating the pump. Re-do clearances if rubbing occurs.

The set clearances may need to be increased if this occurs.

WARNING

Stationary cutter plate should NOT protrude above the volute casing or suction cover. Do NOT

reassemble if this condition exists. Pump will not seal.

Figure 7. Registering Stationary Cutter Plate to Pump Assembly

Loading...

Loading...