3200-632

Aug, 2001

Cornell Pump Company

Page 1 of 2

INSTRUCTIONS FOR MECHANICAL SEAL

JOHN CRANE TYPE 1, TYPE 2, AND TYPE 21 SINGLE MECHANICAL SEAL

For Cornell Solids Handling Pumps

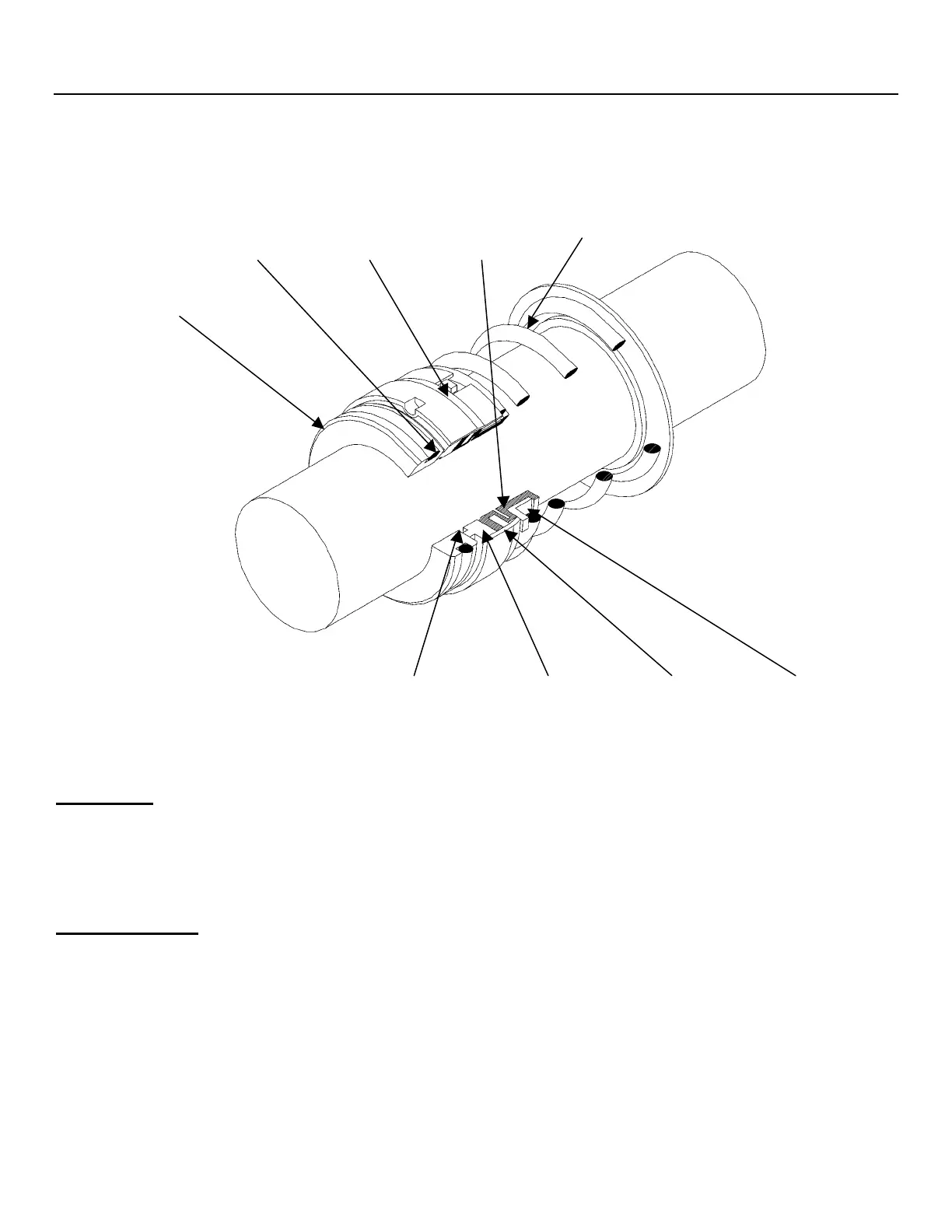

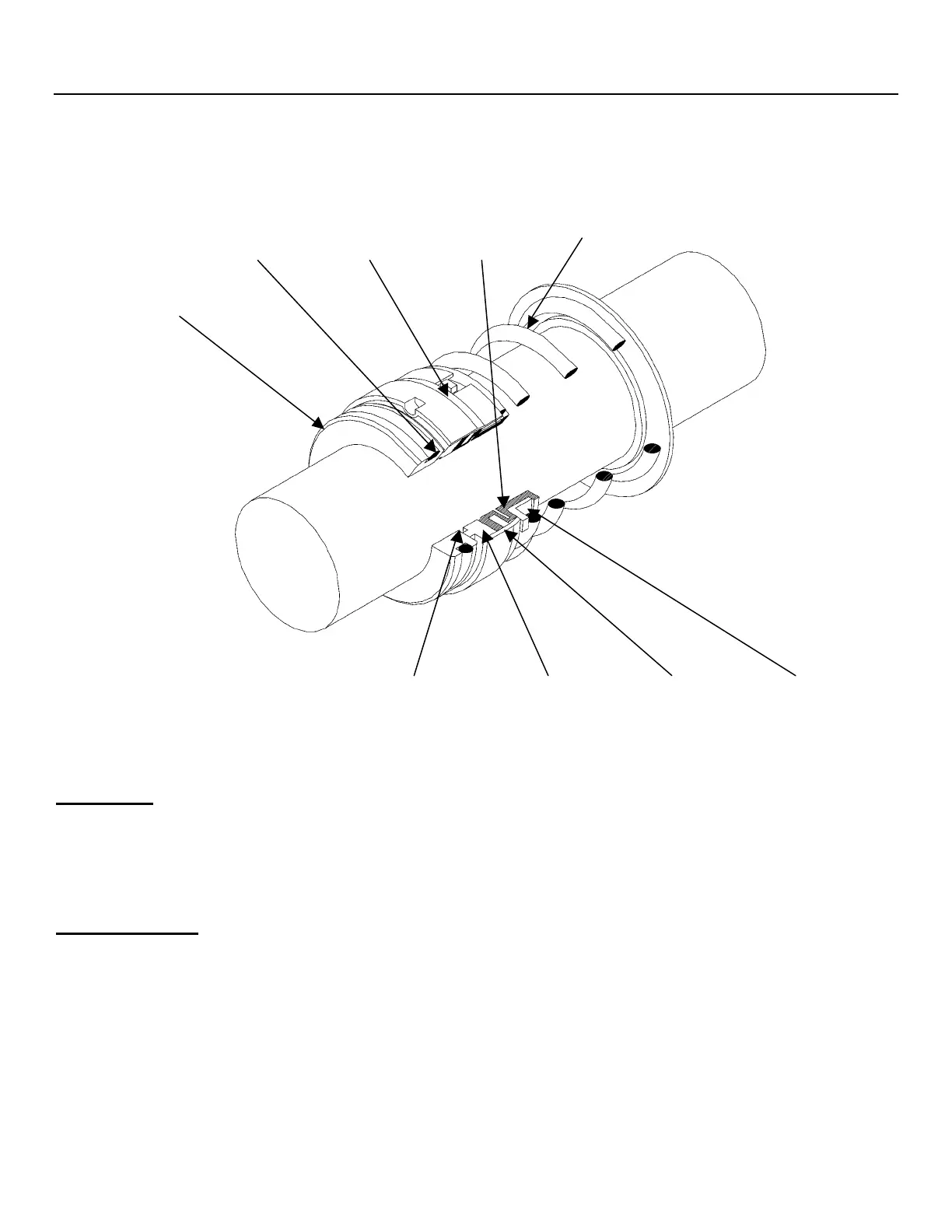

The location of the mechanical seal in your pump is shown in the cross-section drawing of the pump. The

stationary seat is held in the backplate. All other parts of the seal rotate with the shaft and impeller.

STARTING

The seal chamber must be full of liquid before operating the pump. If the shaft is vertical open the vent until

liquid comes out to be sure chamber is full (not necessary for pumps with Cycloseal as seal chamber is self-

venting). CAUTION: DO NOT RUN PUMP DRY unless pump is equipped with Run-Dry option.

MAINTENANCE

No maintenance is required. However, the pump should be examined at regular intervals for leakage resulting

from wear of the sealing faces. Occasionally new installations will leak for a short time. These must be

inspected daily. If the leakage does not reduce to almost zero, the assembly should be examined for proper seal

installation.

SEAL FACE

FACE

DISC DRIVING BAND

SEAT

O-RING SEAT

SPRING

Loading...

Loading...