3200-632

Aug, 2001

Cornell Pump Company

DISMANTLING THE MECHANICAL SEAL Page 2 of 2

If seal is to be removed, remove the impeller according to the instructions for dismantling the pump. The

rotating portion of the seal may now be seen. Slide off the seal spring. Lubricate the shaft and remove the

reminder of the rotating portion being careful to avoid damaging the primary seal. The rubber bellows will be

firmly attached to the shaft and considerable pressure will be required to remove it.

REMOVING SEAT

If the seal is being replaced, remove gland and press out the stationary seat. For pumps with double seals

remove the seat from the stuffing box also.

INSTALLING THE MECHANICAL SEAL

Clean all parts of the pump before starting reassembly. Special attention should be given to the backplate and

the impeller hub.

- Clean and lubricate the shaft.

- Install the stationary seat in the backplate.

- Oil the outer surface of the seat and the “O” ring with a light oil (not grease). Place a cardboard disc on the

sealing face to avoid damage. Press the seat into the gland or stuffing box using firm steady pressure. Make

sure the seat is all the way in. Slide the gland with the gasket over the shaft.

- Wipe the lapped sealing faces of the seat and the primary seal perfectly clean. Use extreme care to avoid

marking the sealing face or the primary seal. Slide the rotating portion of the seal, including spring on the

shaft.

CAUTION: Once the rotating portion has been placed on the shaft, the rest of the installation must be made at

once. Delay may result in the rubber bellows seizing on the shaft in the wrong position.

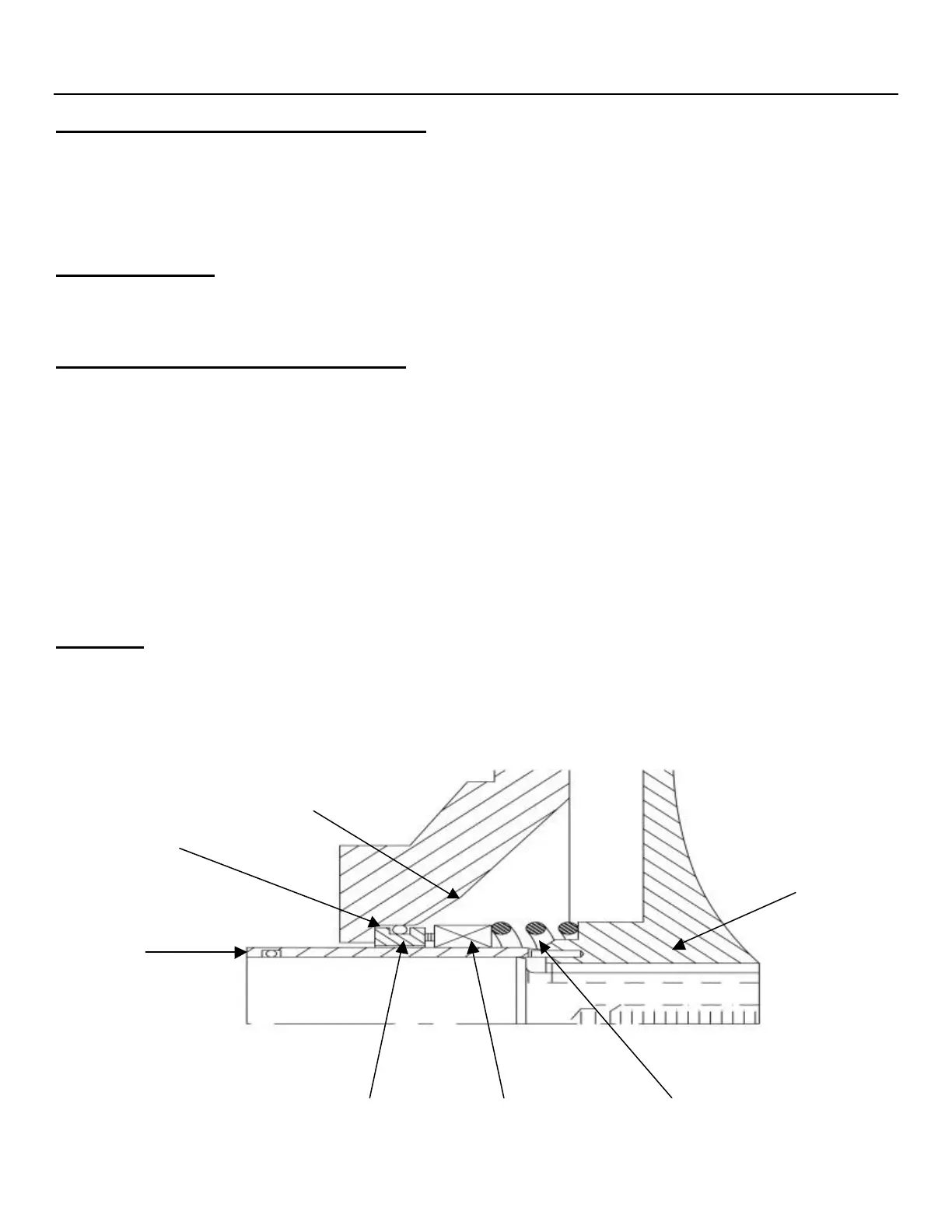

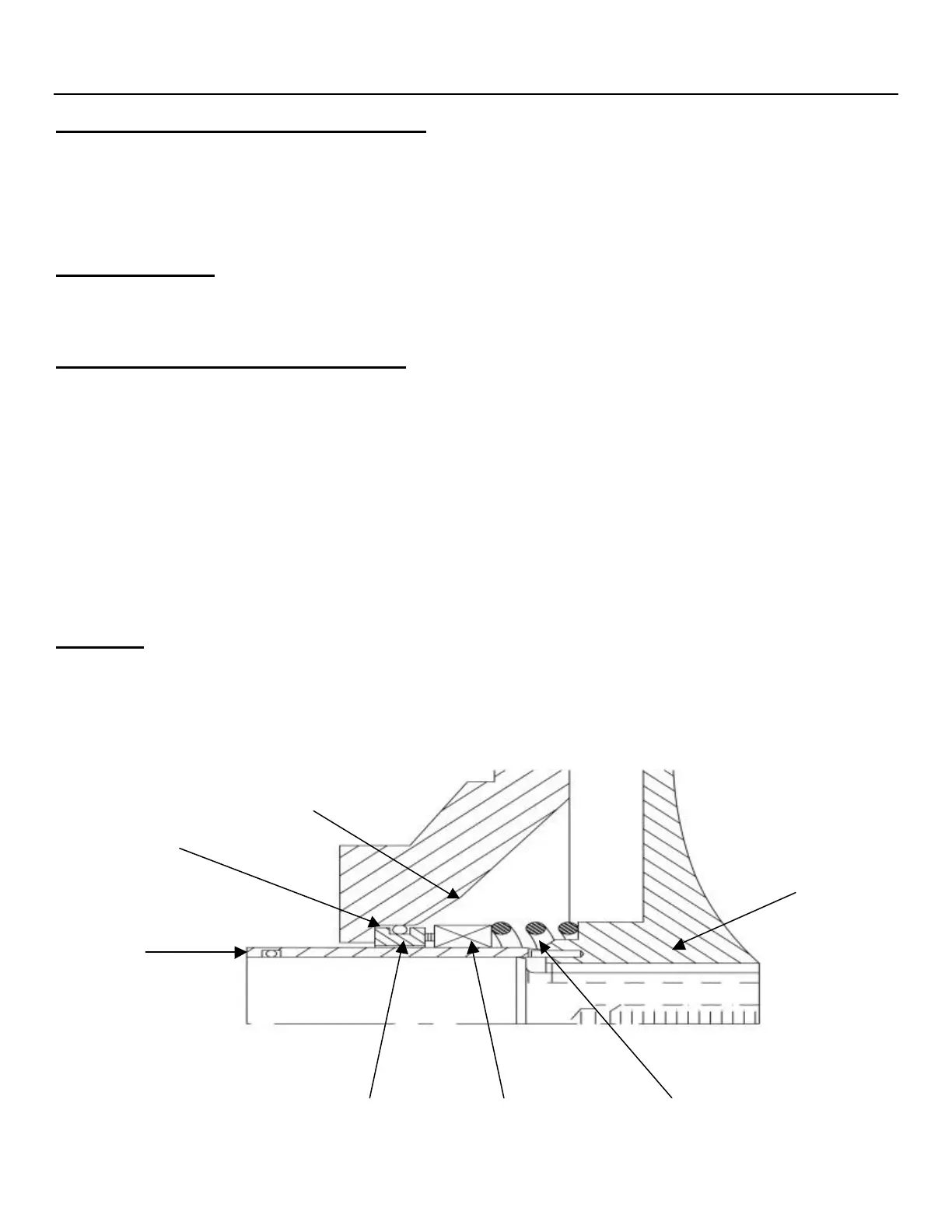

Install the impeller. For pumps with Cycloseal, be sure that the spring slides over the impeller hub and pushes

against the backshroud of the impeller (on some Cycloseal models, a spring retainer or spacer is used to hold the

spring. Refer to pump sectional drawing)

BACKPLATE

IMPELLER

ROTATING ELEMENT SPRING

Typical assembly for Cycloseal pumps

O-RING SEAT

SHAFT SLEEVE

Loading...

Loading...