Supersedes 3200-380

June, ‘88 March, 1990

Cornell Pump Company

PUMP TROUBLE SHOOTING GUIDE

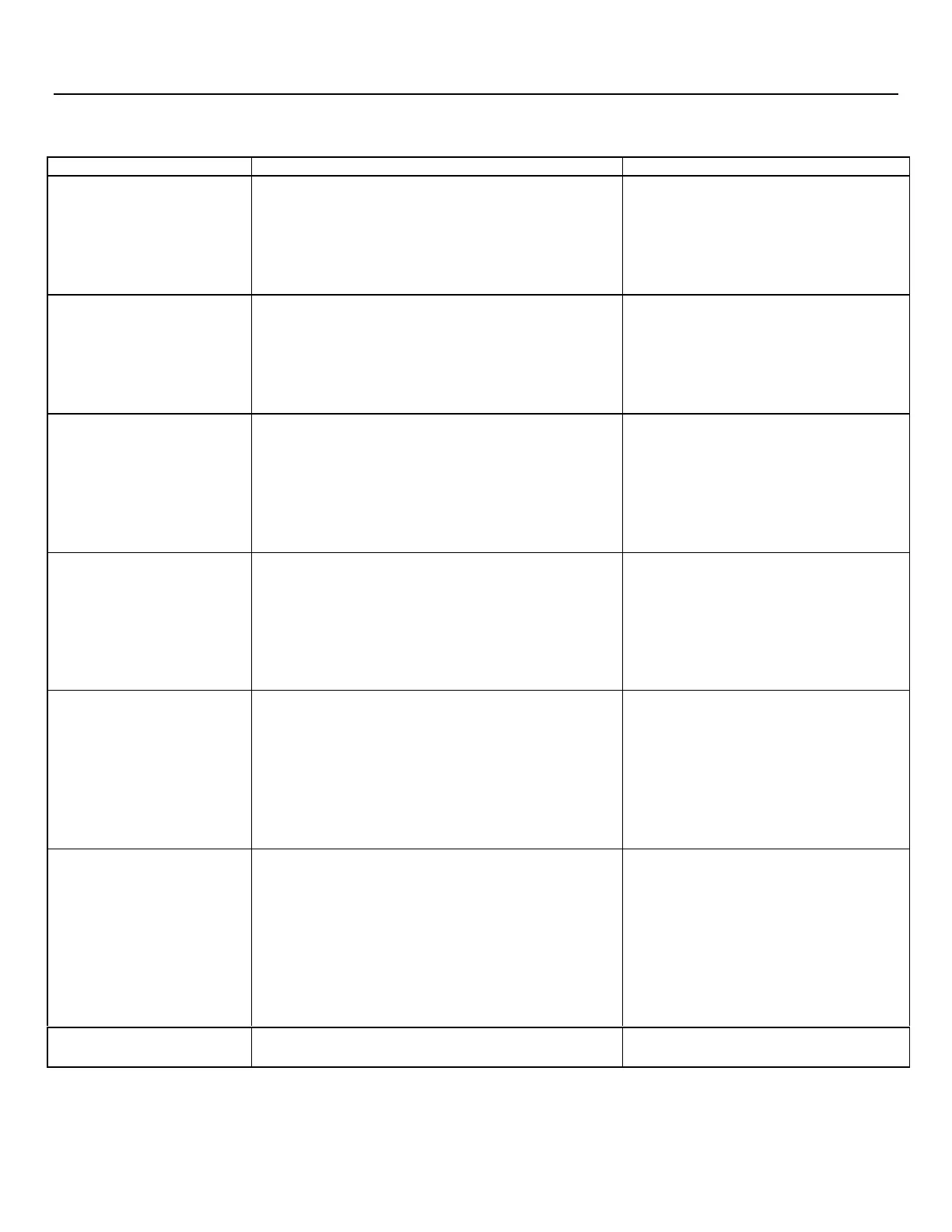

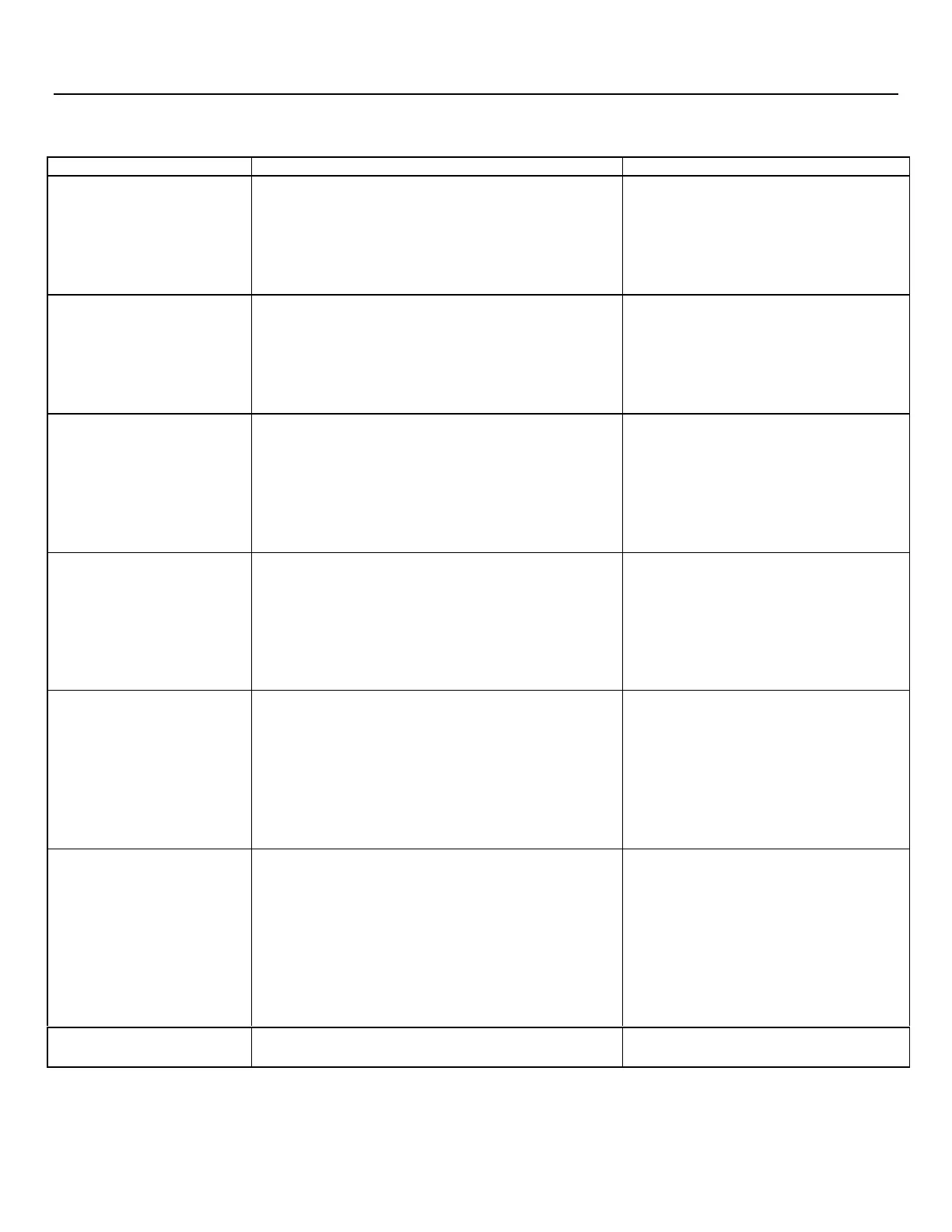

SYMPTOMS CAUSES CORRECTIONS

Failure to pump Pump not properly primed.

Speed too low or head too high.

Not enough head to open check valve.

Air leak.

Plugged suction.

Too high a suction lift.

Prime pump correctly.

Consult Cornell Factory.

Consult Cornell Factory.

Check and rework suction line.

Unplug suction.

Consult Cornell Factory.

Reduced performance Air pockets or small air leaks in suction line.

Obstruction in suction line or impeller.

Insufficient submergence of the suction pipe.

Excessively worn impeller or wear ring.

Too high a suction lift.

Wrong direction of rotation.

Locate and correct.

Remove obstruction.

Consult Cornell Factory.

Replace impeller and/or wear ring.

Consult Cornell Factory.

See start-up instructions.

Driver overloaded Speed higher than planned.

Liquid specific gravity too high.

Liquid handled of greater viscosity than water.

Too large an impeller diameter.

Low voltage.

Stress in pipe connection to pump.

Packing too tight.

Reduce speed.

Consult Cornell Factory.

Consult Cornell Factory.

Trim impeller.

Consult power company.

Support piping properly.

Loosen packing gland nuts.

Excessive noise Misalignment.

Excessive suction lift.

Material lodged in impeller.

Worn bearings.

Impeller screw loose or broken.

Cavitation (improper suction design).

Wrong direction of rotation.

Align all rotating parts.

Consult Cornell Factory.

Dislodge.

Replace bearings.

Replace.

Correct suction piping.

See start-up instructions.

Premature bearing failure Balance line plugged or pinched.

Worn wear rings.

Misalignment.

Suction or discharge pipe not properly supported.

Bent shaft.

Water or contaminates entering bearings.

Lubrication to bearings not adequate.

Wrong type of lubrication.

Unplug or replace.

Replace.

Align all rotating parts.

Correct supports.

Replace shaft.

Protect pump from environment.

See Lubrication Instr. (O&M Manual).

See Lubrication Instr. (O&M Manual).

Electric motor failure High or low voltage.

High electric surge.

Poor electric connection.

Overloads.

Bearing failure.

Cooling vent plugged (roden, leaves, dirt, etc.)

Water is sucked into motor.

Check voltage with voltage meter.

Monitor voltage and consult power co.

Turn power off, clean and check

connections.

Check amperage. Do not exceed

nameplate full load amperage.

Change bearings in motor.

Install proper screens.

Protect pump from environment.

Rapid wear on coupling

cushion

Misalignment.

Bent shaft.

Align.

Replace shaft.

Loading...

Loading...