Page 14 Page 15

Collector AdjustmentsPowered Collector

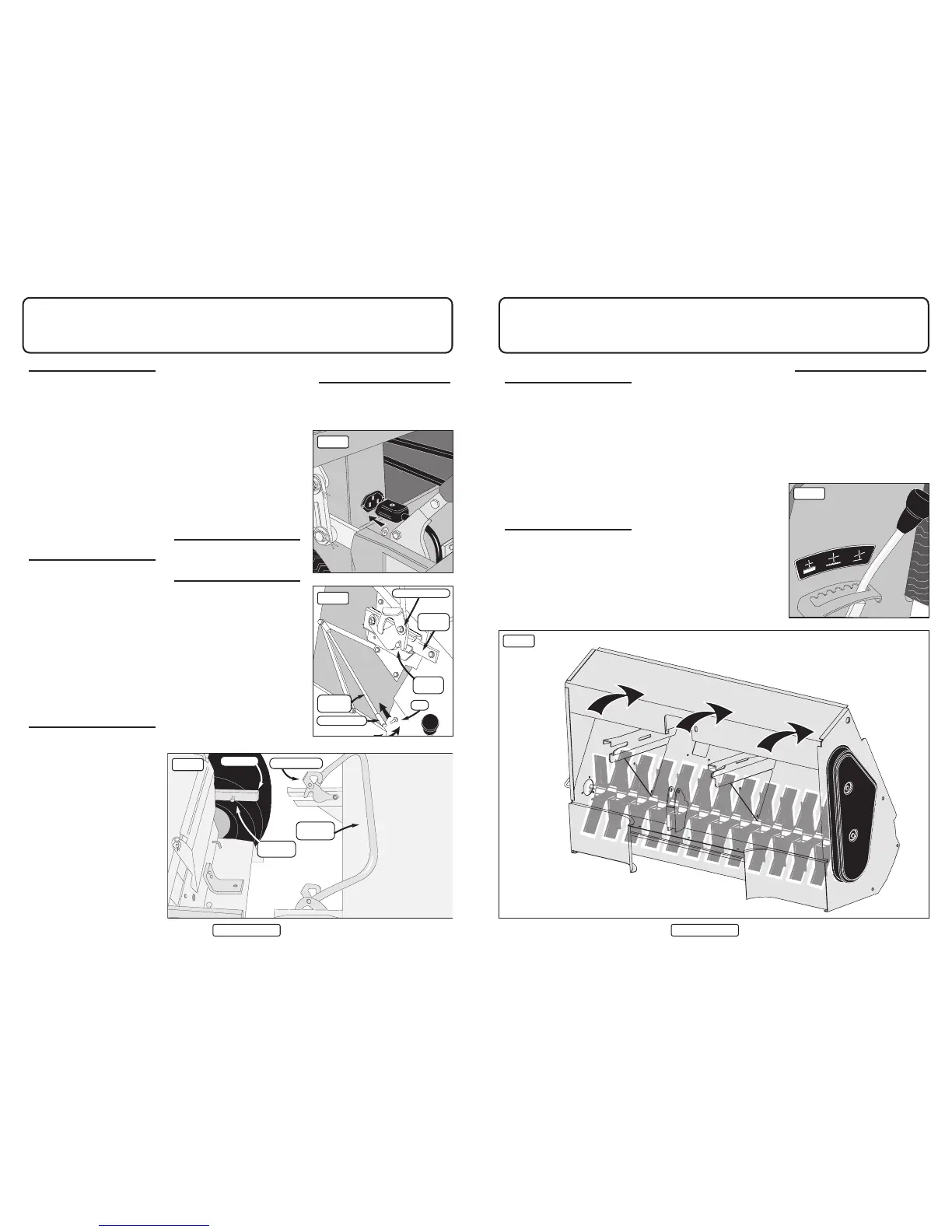

CONNECTION

To connect the Powered Collector to the

Tractor, ensure that both are on an even

surface with the Locking Levers (fig 3)

on the collector facing the Lift Arms on

the Tractor. Move the collector manually

to the Tractor. Lower the Lift Arms using

the button (Page 6 fig 3) on the dash

console.

At the end of each Lift Arm you will find

a Locating Lug . Slide the Channels on

either side of the Powered Collector over

the Lugs but do not engage the Locating

Lever yet. Ensure that the Rubber Flap at

the opening of the PGC locates on top of

the Transmission Grass Deflector.

INSTALLING THE DRIVE

BELT

Place the Drive Belt over the PTO pulley

(beneath the Tractor seat). Standing

adjacent to the Tractor, extend the belt

with both hands parallel to the ground.

Now twist the belt to form a figure ‘8’-

the right-hand up and the left-hand down.

In this position place the other end of the

belt over the Powered Collector Pulley.

Be sure that this is installed the right way

round otherwise the brush will work in

reverse and collection will be poor!

Lock Locating Lever (fig 3) over the Lift

Arm Lugs . Rotate Locking Clips over

Lift Arm Lugs.

PTO DRIVE BELT TENSION

Engaging the Locating Lever tensions the

belt which should not be run too tight - to

check the tension there should be a 19mm

deflection with light finger pressure

(2Kgs) at a midway point between PTO

pulley and Sweeper pulley. It is

important after attaching the Sweeper to

the Tractor, to check the Belt Tension and

adjust this if necessary; this must be done

before the Sweeper is put into operation

and with the Sweeper on the ground.

With light finger pressure, 2kgs (4lbs),

there should be a total deflection of

19mm (3/4”) at midway point between

PTO pulley and the Sweeper pulley. If a

spring balance is available a pressure of

4-5lbs (1.81-2.26Kgs) is required for a

deflection of 3/4” (19mm).If the Belt

Tension is incorrect it can be adjusted by

movement of Sweeper Locking Levers

on the threaded rod. Ensure the lock nuts

are suitably tightened after adjustment.

N.B. Do not overtighten lock nuts as

lever needs to pivot.

TO USE: RAISE SWEEPER TO THE

TRANSPORT POSITION

Using the switch on the dashboard, lift

the PGC to the transport position. We

recommend that you drive to and from

the area to be swept with the Powered

Collector in this transport position and

with the P.T.O disengaged.

When you reach the area to be swept,

lower the collector and then engage the

brushes by pushing the sprung PTO lever

to the right to release and engage.

LOWER THE COLLECTOR

Using the lever (page 15 fig 2), lower the

collector.

REMOVING THE NET

When removing the net, we suggest you

employ the assistance of another person.

1. Partially open the Sweeper net

(100mm (4”)). Disconnect opening rod

by pulling back on sprung locking tube

and uncoupling from pin (fig 2).

2. Repeat either side.

3. Undo net locking clip (both sides),

unhook levers from locating pins

(see fig 2).

4. With either person standing each side

of the collector net, slide the net off the

locating arms.

5. Reverse operation for fitting.

fig 1

fig 2

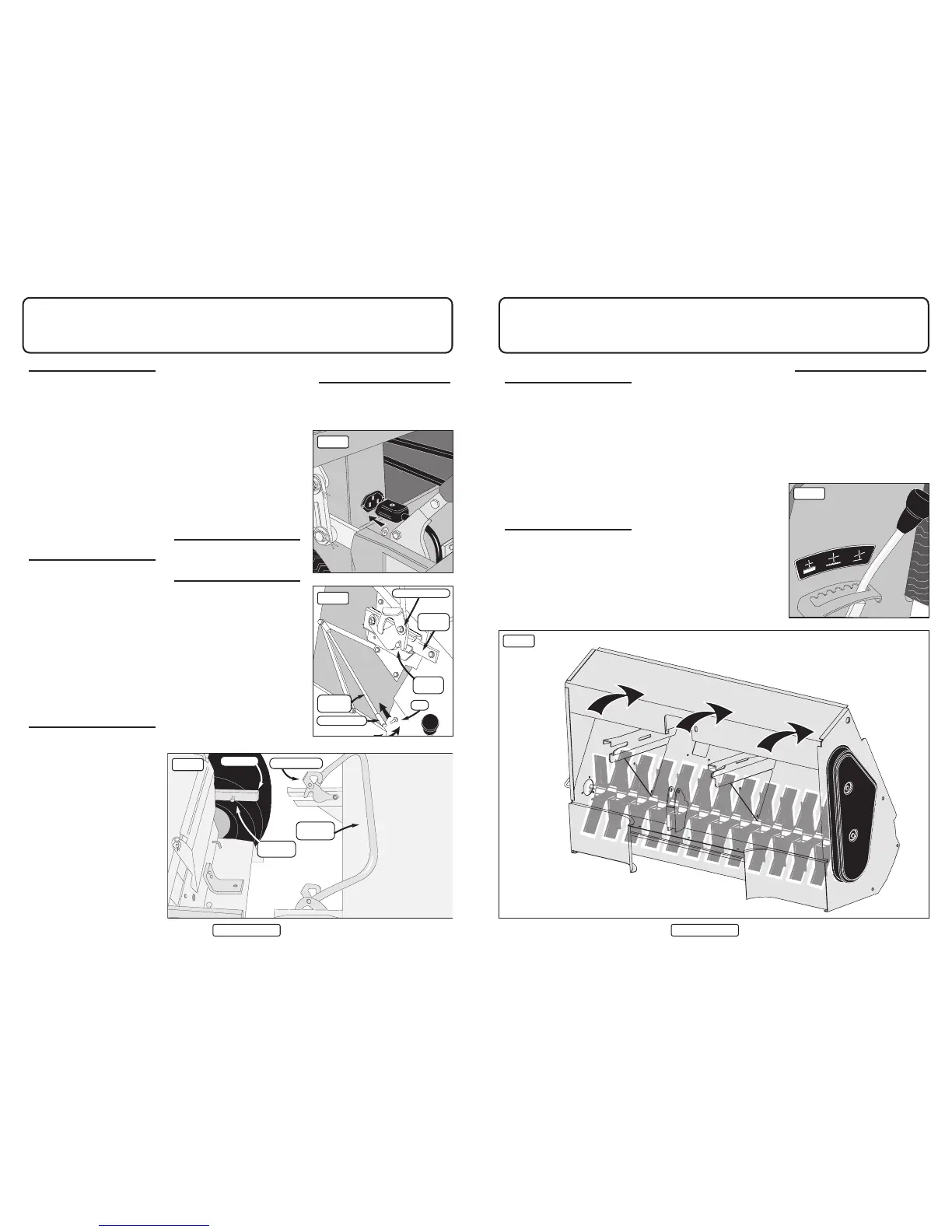

Correct

Rotation

fig 1

ADJUST THE SWEEPING

HEIGHT

Using the Sweeping Height Lever (fig 2)

select the position appropriate to the

conditions and the height of cut. TO GET

THE BEST SWEEPING

PERFORMANCE AND TO PRESERVE

THE BRUSHES SELECT THE

HIGHEST SETTING THAT WORKS -

start high and adjust down until the

brushes stop to collect (normally the

middle adjustment hole). DO NOT SET

THE BRUSHES TOO LOW - this will

lead to scarifying and a very untidy finish

as well as shortening brush life.

CHECK LIST

Not picking up satisfactorily – check:

1. That the PTO lever is engaged.

2. That PTO pulley beneath the seat is

turning – if not call your dealer.

3. That the Collector Belt is not reversed

(if it is correct the brush revolves

against the forward direction of the

Tractor – see below).

4. That the brush height adjustment is not

too high or too low – start at the

highest setting and lower until it begins

to collect.

5. That there is not a build up of

congealed grass on the

leading edge of the Brush Guard.

6. That the Brush is not clogged.

7. That the Collector Belt is not slipping.

If so:

* Adjust tension (see page 16).

* Or replace worn or damaged Belt

(see page 16).

8. That the Collector net is not clogged. If

so wash, or brush with a stiff hand

brush.

9. That the Brush is not damaged (if so

you can replace individual comb

brushes or fit a complete new brush

(see page 17).

10.That the Ventilation Slots on the top of

the Collector Box are not clogged.

11.That the Venturi Air Vent is not

blocked.

TO TIP CUTTINGS

You can check the contents of the grass

box through the clear cover. When it is full,

raise the collector to the transport position.

Drive to your tipping area, reverse to the

pile, select neutral, then depress the

PGC

Net Empty Switch

(page 4 fig 1).

fig 2

fig 3

Locating

Lever

Lift Arm

Locating

Lug

Opening

Rod

Locking Clips

Locating

Pins

Locking Tube

Pin

Net Locking clip

CONNECTING NET EMPTY

SOCKET

Connect Net Empty plug to socket as

shown in fig 1. To disconnect, reverse this

procedure.

Locating

Arms

Loading...

Loading...