4, Removethechipperchutesupportbracefromthe frameby

removingthehexbolts.

5. Rotateimpellerassemblyby handuntilyoulocateone of two

chipperbladesin thechipperchuteopening.

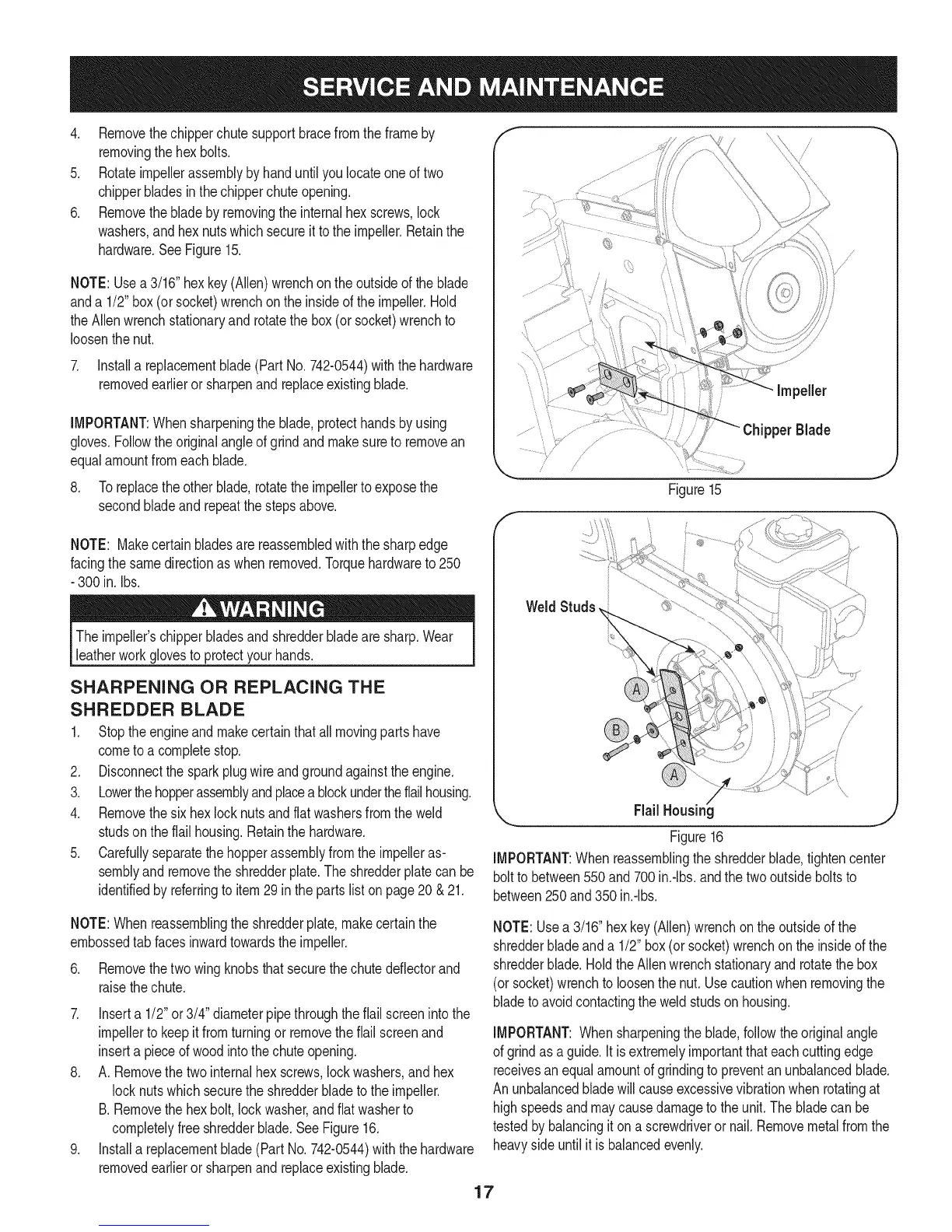

6, Removethebladebyremovingthe internalhex screws,lock

washers,andhexnutswhichsecureit tothe impeller.Retainthe

hardware,SeeFigure15,

NOTE:Usea3/16"hexkey(Allen)wrenchon theoutsideof theblade

anda 1/2"box(or socket)wrenchonthe insideof theimpeller.Hold

theAllenwrenchstationaryand rotatethe box(or socket)wrenchto

loosenthenut.

7. Installa replacementblade(PartNo.742-0544)withthe hardware

removedearlieror sharpenand replaceexistingblade.

IMPORTANT:Whensharpeningthe blade,protecthandsbyusing

gloves.Followthe originalangleofgrindandmakesureto removean

equalamountfromeachblade.

8. To replacetheother blade,rotatetheimpellerto exposethe

secondbladeand repeatthe stepsabove.

NOTE: Makecertainbladesare reassembledwiththe sharpedge

facingthesamedirectionas whenremoved.Torquehardwareto 250

- 300in.Ibs.

Theimpeller'schipperbladesand shredderbladearesharp.Wear

leatherworkglovestoprotectyour hands.

SHARPENING OR REPLACING THE

SHREDDER BLADE

1. Stopthe engineandmakecertainthatallmovingpartshave

cometoa completestop.

2. Disconnectthesparkplugwire andgroundagainsttheengine.

3. Lowerthehopperassemblyandplacea blockundertheflailhousing.

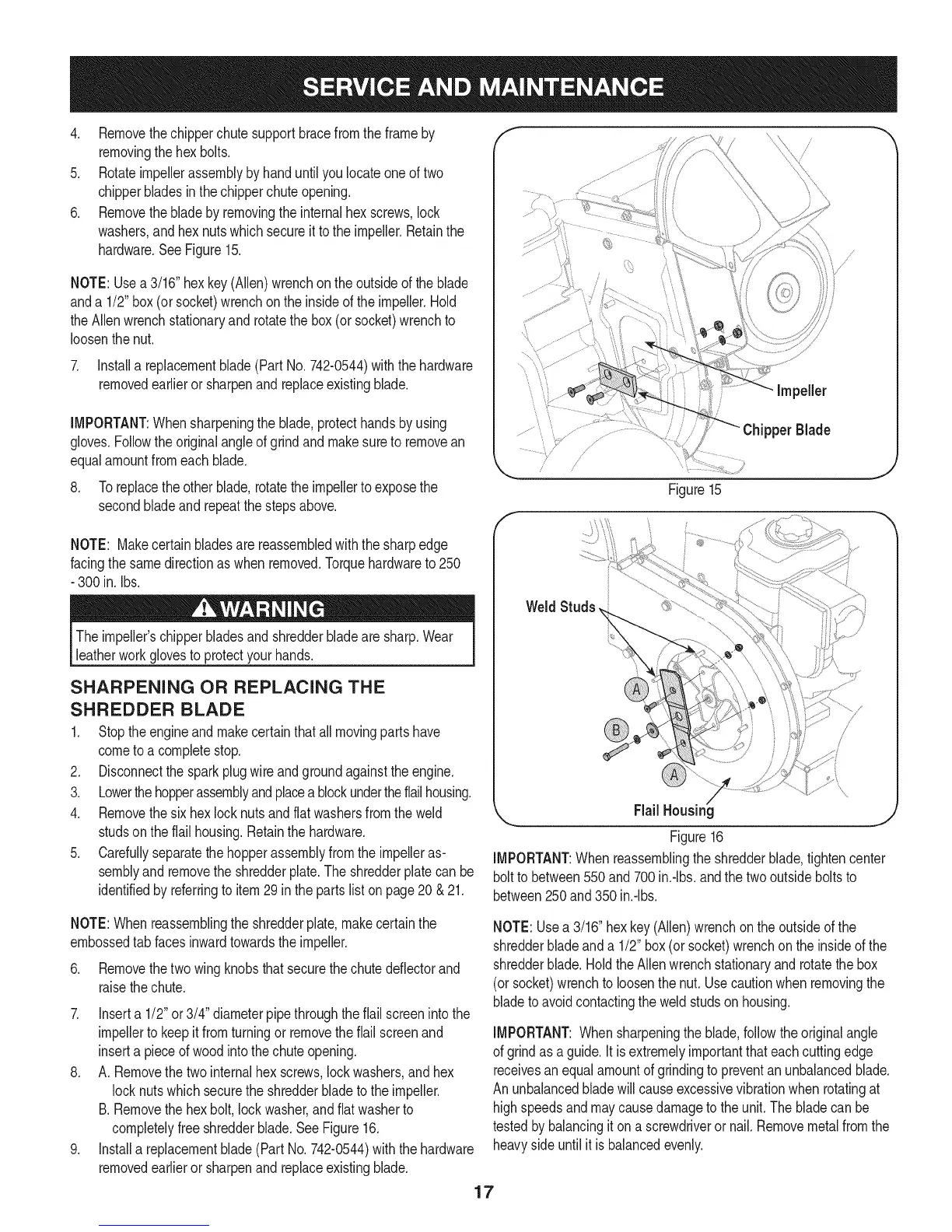

4. Removethesix hexlocknutsandflatwashersfromthe weld

studsonthe flailhousing.Retainthe hardware.

5. Carefullyseparatethe hopperassemblyfromthe impelleras-

semblyand removethe shredderplate.Theshredderplatecan be

identifiedby referringto item29in thepartsliston page20 &21.

Impeller

Blade

J

Figure15

Weld Studs,

/

Flail Housing

Figure16

IMPORTANT:When reassemblingtheshredderblade,tightencenter

boltto between550and700in.-Ibs,andthetwooutsideboltsto

between250and350in.-Ibs.

NOTE:Whenreassemblingtheshredderplate,makecertainthe

embossedtab facesinwardtowardstheimpeller.

6. Removethetwo wingknobsthatsecurethe chutedeflectorand

raisethe chute.

7. Inserta 1/2"or3/4" diameterpipethroughthe flailscreenintothe

impellertokeepit fromturningor removethe flailscreenand

inserta pieceof woodintothe chuteopening.

8. A. Removethe twointernalhex screws,lockwashers,andhex

locknutswhichsecurethe shredderbladeto theimpeller.

B.Removethe hexbolt,lockwasher,andflat washerto

completelyfreeshredderblade.SeeFigure16.

9. Installa replacementblade(Part No.742-0544)withthehardware

removedearlieror sharpenandreplaceexistingblade.

NOTE:Usea 3/16"hex key(Allen)wrenchontheoutsideof the

shredderbladeanda 1/2"box(or socket)wrenchon theinsideofthe

shredderblade.Holdthe Allenwrenchstationaryand rotatethebox

(orsocket)wrenchtoloosenthe nut. Usecautionwhenremovingthe

bladetoavoidcontactingtheweldstudson housing.

IMPORTANT:Whensharpeningthe blade,followtheoriginalangle

ofgrindas a guide.It is extremelyimportantthateachcuttingedge

receivesan equalamountof grindingtopreventan unbalancedblade.

An unbalancedbladewill causeexcessivevibrationwhen rotatingat

highspeedsandmaycausedamageto theunit.The bladecanbe

testedby balancingit on ascrewdriverornail. Removemetalfromthe

heavysideuntil itis balancedevenly.

17

Loading...

Loading...