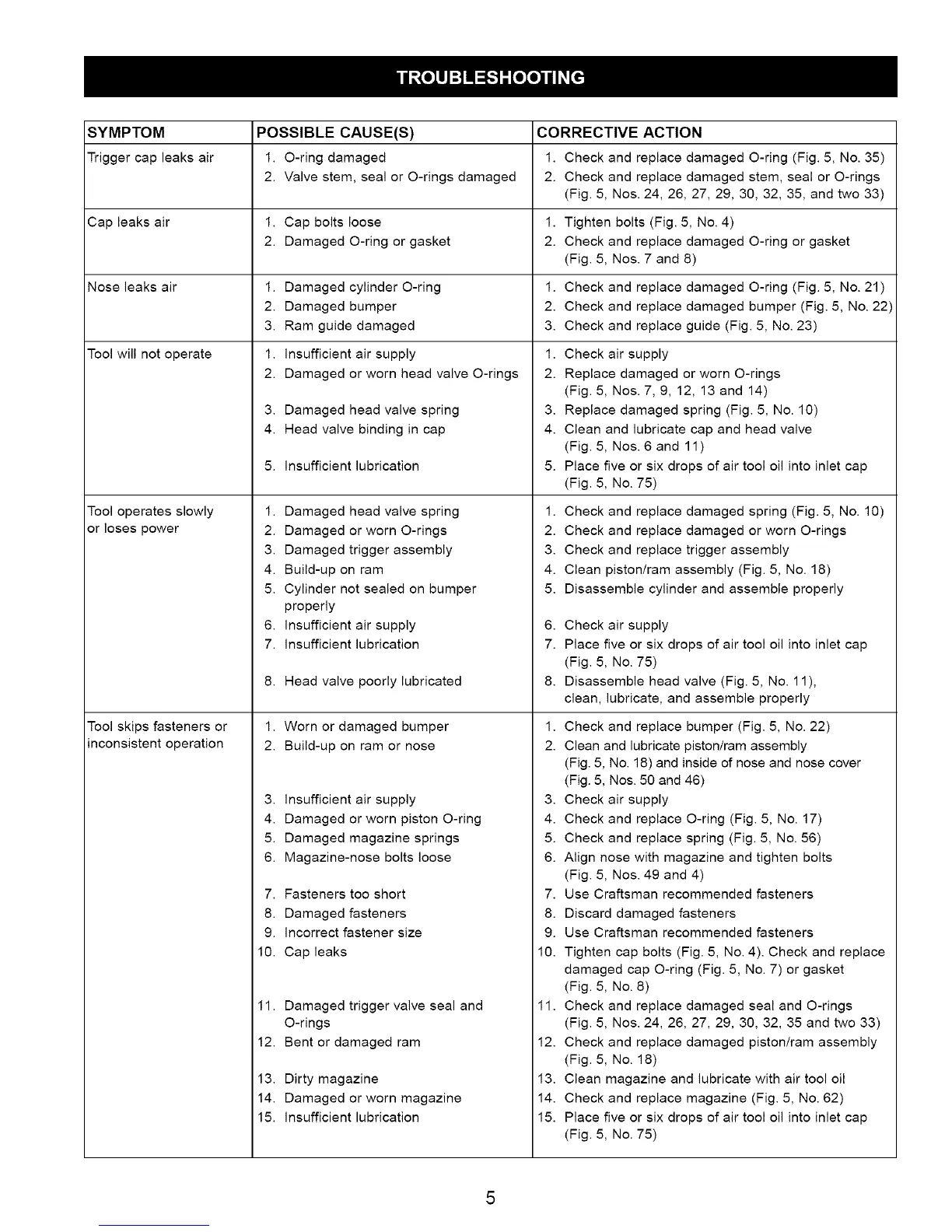

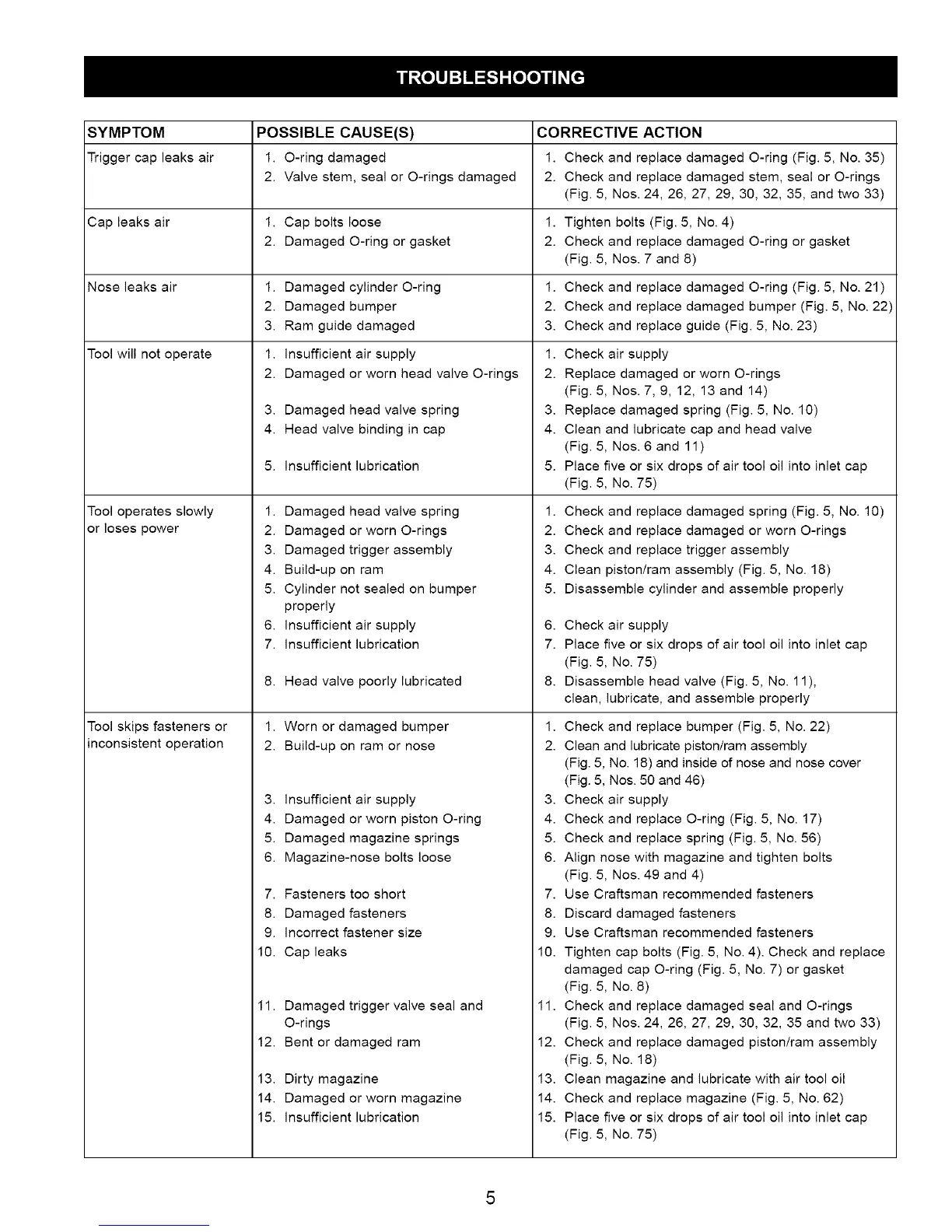

SYMPTOM POSSIBLE CAUSE(S)

Trigger cap leaks air 1. O-ring damaged

2. Valve stem, seal or O-rings damaged

Cap leaks air

Nose leaks air

Tool will not operate

Tool operates slowly

or loses power

Tool skips fasteners or

inconsistent operation

1. Cap bolts loose 1.

2. Damaged O-ring or gasket 2.

1. Damaged cylinder O-ring 1.

2. Damaged bumper 2.

3. Ram guide damaged 3.

1. Insufficient air supply 1.

2. Damaged or worn head valve O-rings 2.

3. Damaged head valve spring

4. Head valve binding in cap

5. insufficient lubrication

1. Damaged head valve spring

2. Damaged or worn O-rings

3. Damaged trigger assembly

4. Build-up on ram

5. Cylinder not sealed on bumper

properly

6. insufficient air supply

7. Insufficient lubrication

8. Head valve poorly lubricated

1. Worn or damaged bumper

2. Build-up on ram or nose

3. insufficient air supply

4. Damaged or worn piston O-ring

5. Damaged magazine springs

6. Magazine-nose bolts loose

7. Fasteners too short

8. Damaged fasteners

9. incorrect fastener size

10. Cap leaks

11.

12.

13.

14.

15.

Damaged trigger valve seal and

O-rings

Bent or damaged ram

Dirty magazine

Damaged or worn magazine

insufficient lubrication

CORRECTIVE ACTION

1. Check and replace damaged O-ring (Fig. 5, No. 35)

2. Check and replace damaged stem, seal or O-rings

(Fig. 5, Nos. 24, 26, 27, 29, 30, 32, 35, and two 33)

Tighten bolts (Fig. 5, No. 4)

Check and replace damaged O-ring or gasket

(Fig. 5, Nos. 7 and 8)

Check and replace damaged O-ring (Fig. 5, No. 21)

Check and replace damaged bumper (Fig. 5, No. 22)

Check and replace guide (Fig. 5, No. 23)

Check air supply

Replace damaged or worn O-rings

(Fig. 5, Nos. 7, 9, 12, 13 and 14)

3. Replace damaged spring (Fig. 5, No. 10)

4. Clean and lubricate cap and head valve

(Fig. 5, Nos. 6 and 11 )

5. Place five or six drops of air tool oil into inlet cap

(Fig. 5, No. 75)

1. Check and replace damaged spring (Fig. 5, No. 10)

2. Check and replace damaged or worn O-rings

3. Check and replace trigger assembly

4. Clean piston/ram assembly (Fig. 5, No. 18)

5. Disassemble cylinder and assemble properly

6. Check air supply

7. Place five or six drops of air tool oil into inlet cap

(Fig. 5, No. 75)

8. Disassemble head valve (Fig. 5, No. 11),

clean, lubricate, and assemble properly

1. Check and replace bumper (Fig. 5, No. 22)

2. Clean and lubricate pistonlram assembly

(Fig. 5, No. 18) and inside of nose and nose cover

(Fig. 5, Nos. 50 and 46)

3. Check air supply

4. Check and replace O-ring (Fig. 5, No. 17)

5. Check and replace spring (Fig. 5, No. 56)

6. Align nose with magazine and tighten bolts

(Fig. 5, Nos. 49 and 4)

7. Use Craftsman recommended fasteners

8. Discard damaged fasteners

9. Use Craftsman recommended fasteners

10. Tighten cap bolts (Fig. 5, No. 4). Check and replace

damaged cap O-ring (Fig. 5, No. 7) or gasket

(Fig. 5, No. 8)

11. Check and replace damaged seal and O-rings

(Fig. 5, Nos. 24, 26, 27, 29, 30, 32, 35 and two 33)

12. Check and replace damaged piston/ram assembly

(Fig. 5, No. 18)

13. Clean magazine and lubricate with air tool oil

14. Check and replace magazine (Fig. 5, No. 62)

15. Place five or six drops of air tool oil into inlet cap

(Fig. 5, No. 75)

Loading...

Loading...