5 V1.02

LIST OF ITEMS

Position Quantity Designation of the itme

1 1 Ball valve G1/2“, threepart, made of stainless-steel

2 1 Fastening plate

3 1 Upper plate

4 2 Thread bars

5 2 Guide bars

6 2 Wing nuts

Fastening nuts and washers

A = Counter nuts

ALIGNMENT OF THE SENSOR

Safety information must be observed.

Assembly is carried out by inserting the connection thread (1/2“ thread, SW 27) into the

connection piece of the ball valve.

Once the sensor has been aligned, the adapter sleeve must be tightened with the stipulated

torque (20 - 30 Nm - SW 17).

Attention: Alignment of the sensor must not be modified when tightening the connection

thread and adapter sleeve. In this case please check the immersion depth and alignment

again and correct if necessary. The angular deviation should not be greater than ± 2° in re-

lation to the ideal position as otherwise the measuring accuracy will decrease.

An undisturbed flow progression is achieved if the sections in front of the sensor (inlet) and

behind the sensor (outlet) are sufficiently long, absolutely straight and without any obstruc-

tions such as edges, seams, curves etc.

For more details please see the instruction manuals of the consumption sensors.

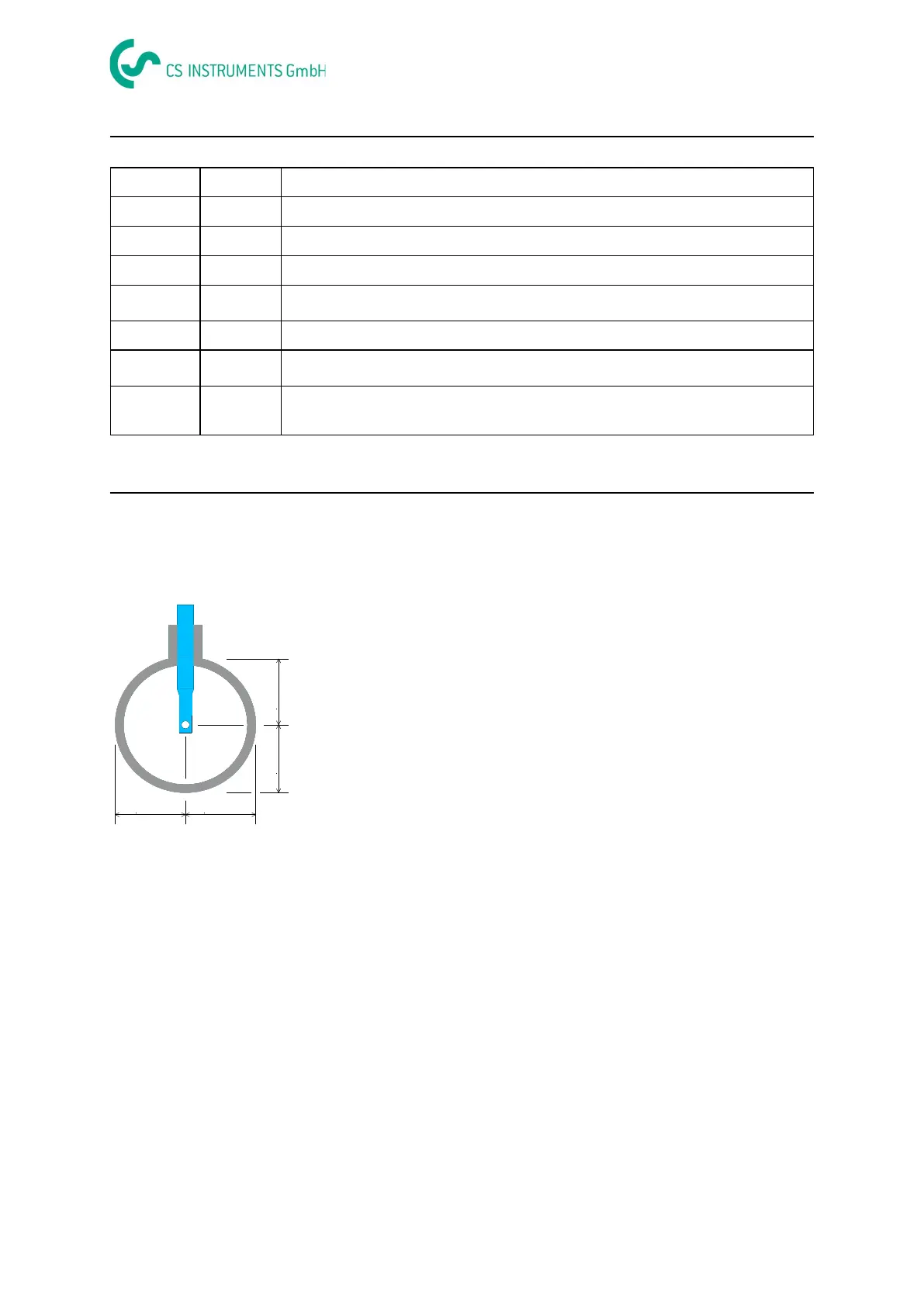

The sensor is then inserted to the required immersion

depth and aligned according to the direction of air flow as

described on page 3. A depth scale engraved on the

probe tube, a flow alignment arrow and an aligning device

will be of help to you.

Loading...

Loading...