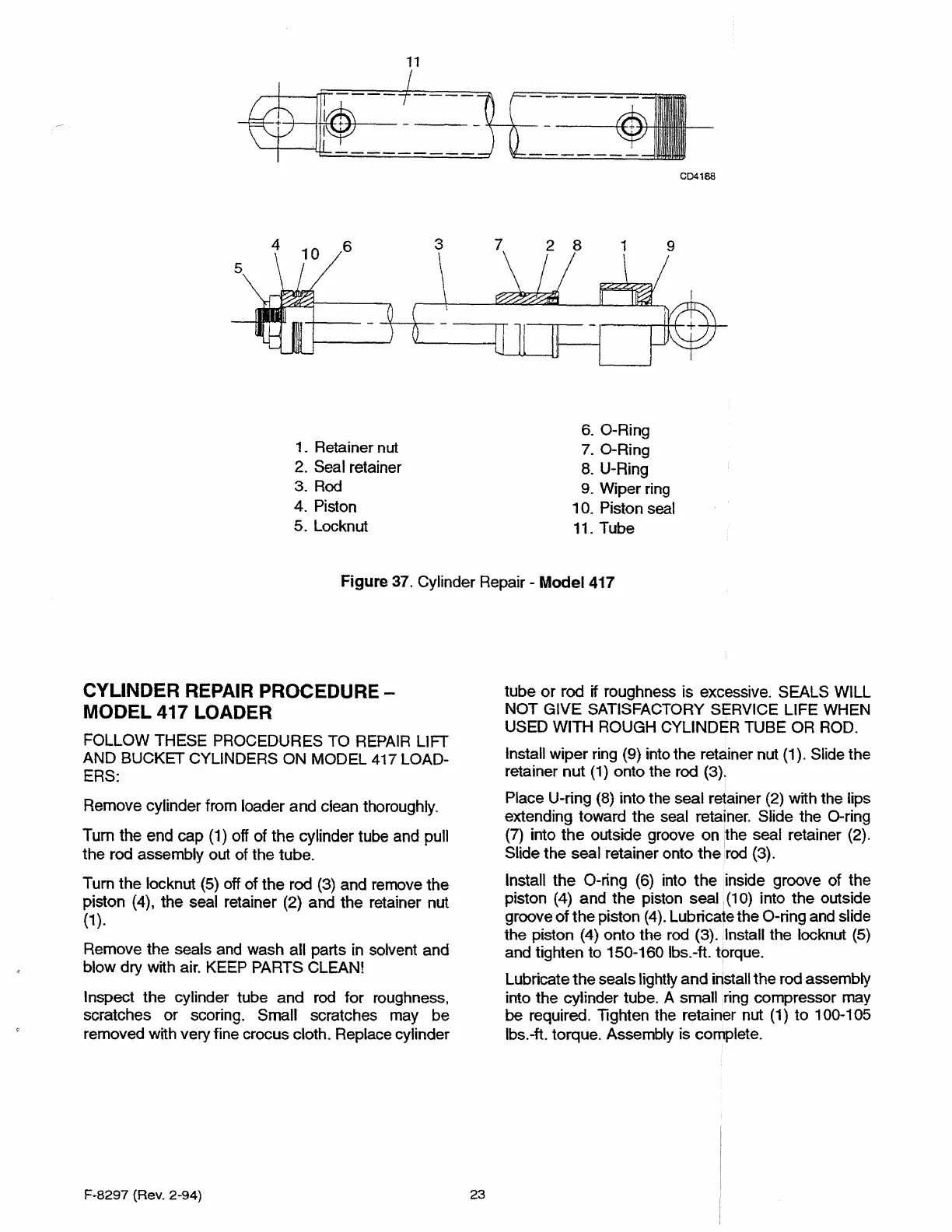

11

CD4188

5

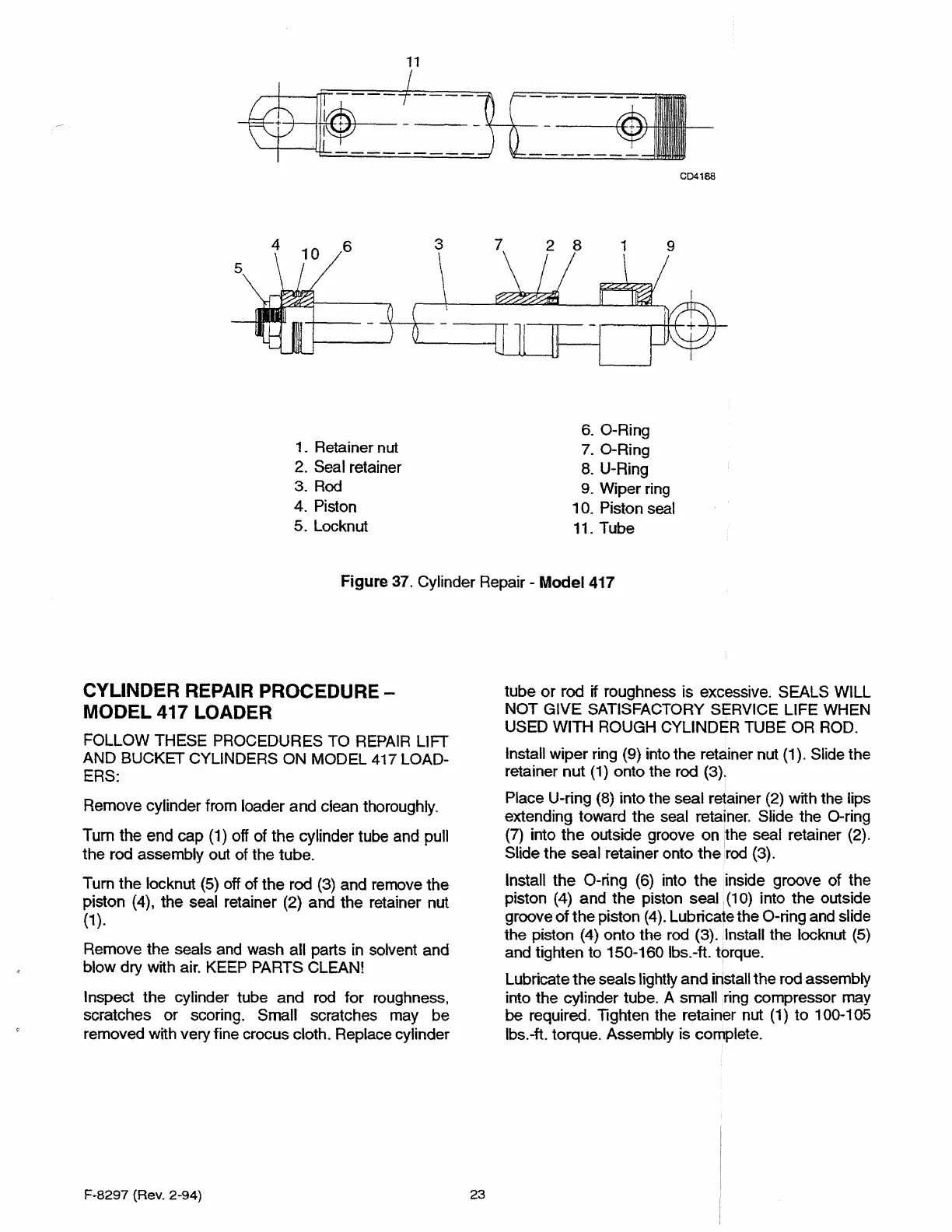

6.

0-Ring

1 . Retainer nut

7.

0-Ring

2. Seal retainer

8. U-Ring

3.

Rod

9.

Wiper ring

4. Piston

10. Piston seal

5. Locknut

11. Tube

Figure 37. Cylinder Repair - Model 417

CYLINDER REPAIR PROCEDURE -

MODEL 417 LOADER

FOLLOW THESE PROCEDURES

TO

REPAIR LIFT

AND BUCKET CYLINDERS ON MODEL

417

LOAD-

ERS:

Remove cylinder from loader and clean thoroughly.

Tum

the end cap (1) off of

the

cylinder tube and pull

the rod assembly out of the tube.

Tum

the

locknut (5) off of the rod (3) and remove the

piston

(4),

the seal retainer (2) and the retainer nut

(1

).

Remove the seals and wash all parts in solvent and

blow dry with air. KEEP PARTS CLEAN!

Inspect

the

cylinder tube and rod

for

roughness,

scratches

or

scoring. Small scratches may be

removed with very fine crocus cloth. Replace cylinder

F-8297 (Rev. 2-94)

23

tube

or

rod if roughness is excessive. SEALS WILL

NOT GIVE SATISFACTORY SERVICE LIFE WHEN

USED WITH ROUGH CYLINDER TUBE OR ROD.

Install wiper ring (9) into the retainer nut

(1

). Slide the

retainer nut (1) onto the rod (3).

Place U-ring (8) into the seal retainer (2) with the lips

extending toward the seal retainer. Slide the 0-ring

(7) into

the

outside groove

on

the

seal retainer (2).

Slide the seal retainer onto

the

1

rod (3).

Install the

0-ring

(6) into

the

inside groove

of

the

piston (4) and

the

piston seal ,(10) into

the

outside

groove

of

the piston (4). Lubricate the

0-ring

and slide

the piston (4) onto the rod (3). Install the locknut (5)

and tighten to 150-160 lbs.-ft. torque.

Lubricate

the

seals lightly and install

the

rod assembly

into the cylinder tube. A small ring compressor may

be required. Tighten the retainer nut (1)

to

100-105

lbs.-ft. torque. Assembly is complete.

Loading...

Loading...