OPERATION

PREPARING TRACTOR

Before operating the loader, for optimum stability,

additional weight should be added

to

the rear of the

tractor with rear wheel weights

or

liquid ballast. Refer

to your tractor operator's manual for weighting

information.

The tractor rear wheels should be moved to the

tractor manufacturer's widest recommended settings

to increase the stability of the tractor.

OPERATING LOADER

The loader should be operated with the tractor engine

running at a safe RPM. Excessive speeds are danger-

ous, and may cause bucket spillage and unnecessary

strain on the tractor and loader.

FILLING

THE

BUCKET

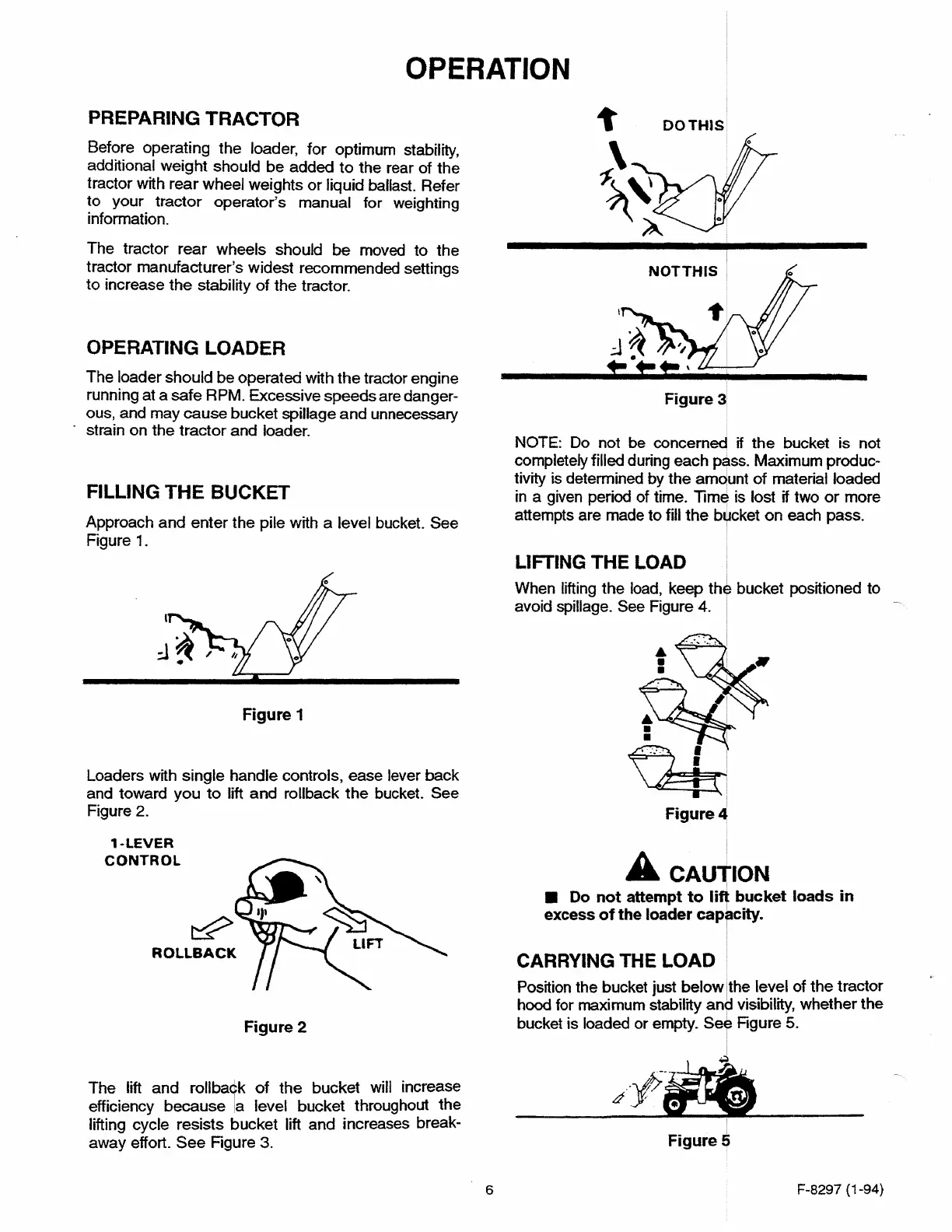

Approach and enter the pile with a level bucket. See

Figure

1.

Figure 1

Loaders with single handle controls, ease lever back

and toward you

to

lift and rollback the bucket. See

Figure 2.

1-LEVER

CONTROL

~

ROLLBACK

Figure 2

The lift and rollbadk

of

the bucket will increase

efficiency because

la

level bucket throughout the

lifting cycle resists bucket lift and increases break-

away effort.

See

Figure 3.

6

DOTHIS

NOTTHIS

i

Figure 3

NOTE: Do not be concerned if

the

bucket is not

completely filled during each pass. Maximum produc-

tivity is determined by the amqunt

of

material loaded

in

a given period of time. Time is lost if two

or

more

attempts are made to fill the

b'l,lcket

on each pass.

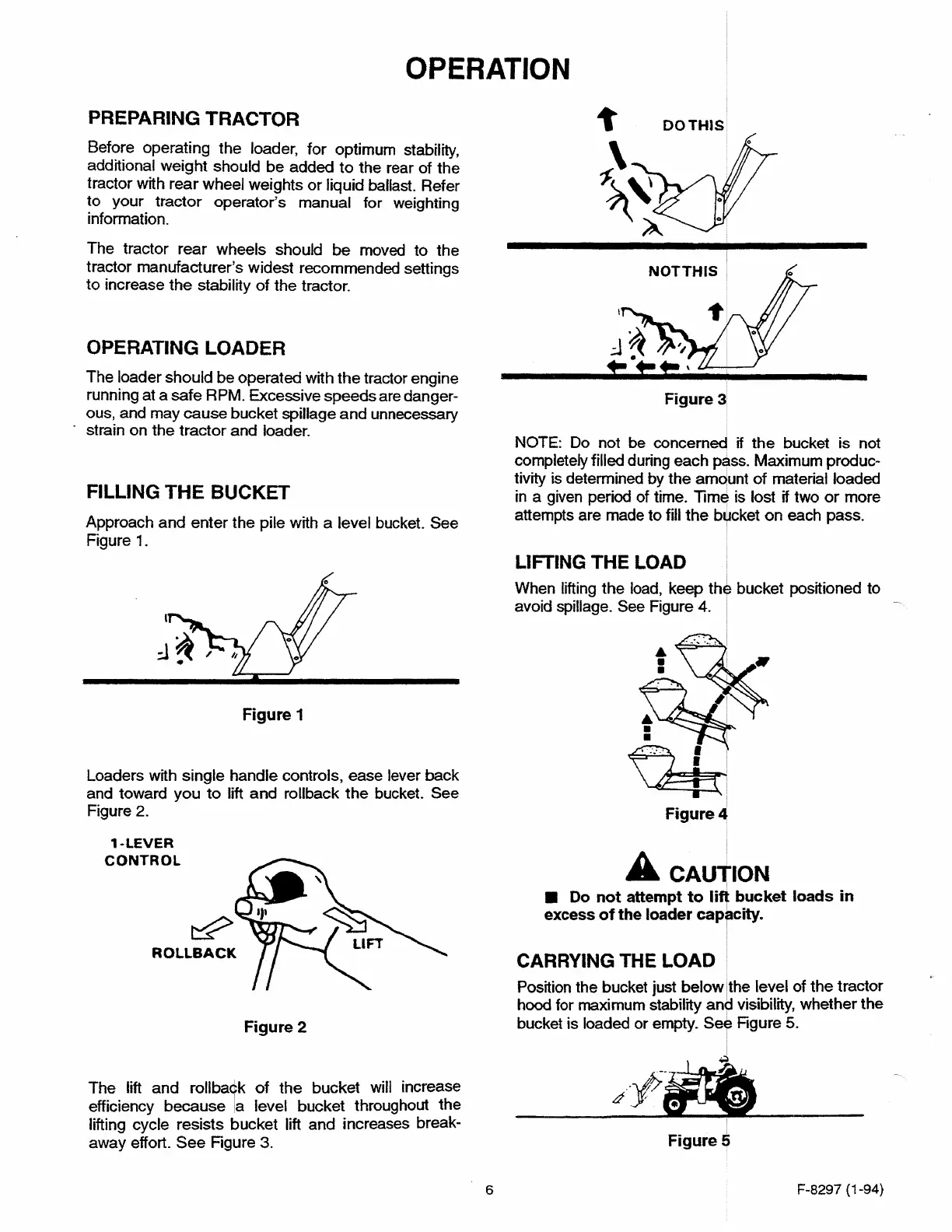

LIFTING THE LOAD

When lifting the load, keep th~ bucket positioned to

avoid spillage. See Figure 4. I

~

~

I

Figure4

I

A CAUTION

■

Do not attempt

to

lift

bucket loads in

excess

of

the loader cap~city.

I

CARRYING THE LOAD

Position the bucket just below

[the

level of the tractor

hood for maximum stability an~ visibility, whether the

bucket is loaded or empty. See Figure

5.

I

I

d-}f-

Figure

5

F-8297 (1-94}

Loading...

Loading...