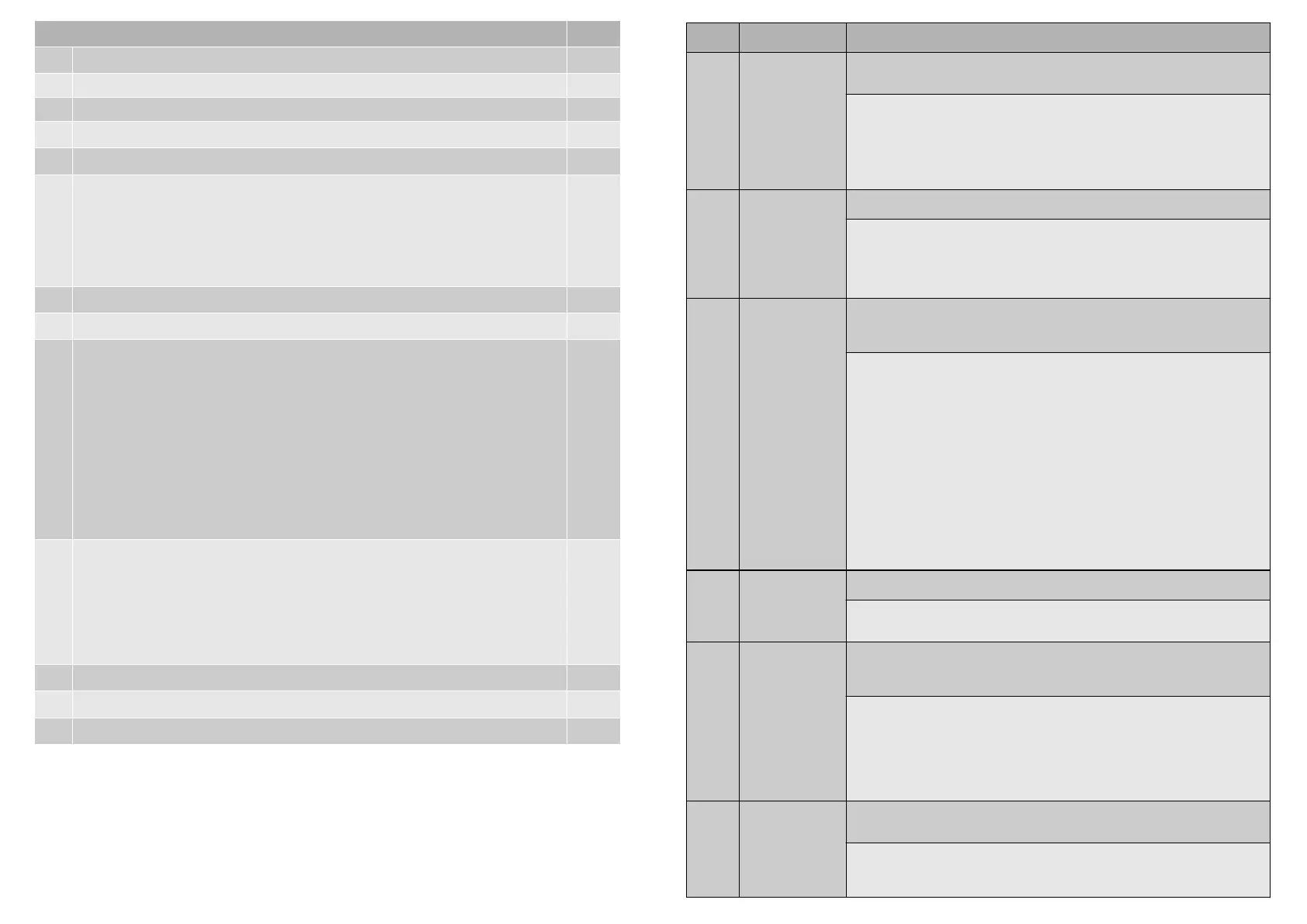

Table of Contents Page

1.0 Foreword 3

2.0 Disclaimer

3.0 Glossary 4

4.0 Technical Specificaons 5

5.0 Parts Idenficaon 6

6.0 Assembling and Installing the Operator

5.1 Vercal Mount Roll Up Drive Channel Posion

5.2 Aaching the Power Head to the Drive Channel

5.3 Aaching the Cross Tube to the Drive Channel

5.4 Mounng the Floang Bracket to the wall

5.5 Aaching Door U-Brackets

5.6 Securing the Drive Channel to the Floor

5.7 Posioning & Securing the Baery

7

7

7

8

9

11

11

7.0 Informaon before programming and commissioning the operator 12

8.0 Seng the Physical Open & Close Limits 13

9.0 Programming the Operator

9.1 Programming Menu

9.2 Seng the Open & Close Limits

9.3 Seng the Opening & Closing Force

9.4 Enable or Disable Safety Beams

9.5 Seng Auto Close

9.6 Seng the Auxiliary Output

9.7 Enable or Disable Electric/Magnec Lock

9.8 Programming Remotes

9.8.1 Programming a Remote Buon to Trigger the Operator

9.8.2 Programming a Remote Buon to Turn the Operator Light On & Off

9.8.3 Erasing a Single Remote and its Buons from the Operator

9.8.4 Erasing All Remotes and their Buons from the Operator

9.8.5 Programming a Remote Buon to set the Holiday Lockout feature

9.8.6 Factory Reset

13

14

14

14

15

15

16

16

17

17

18

18

18

10. Advanced Controller Programming Opons

10.1 Control Board Layout

10.2 External Trigger

10.3 Safety Beams

10.4 Electric and Magnec Locks

10.5 Auxiliary Status Output

10.6 Auxiliary Low Baery Output

10.7 Auxiliary Trigger Output

10.8 Auxiliary Light

19

19

20

20

21

21

22

22

11. Connecng a Solar Panel 22

12. Error Codes 23

13. Warranty 26

2

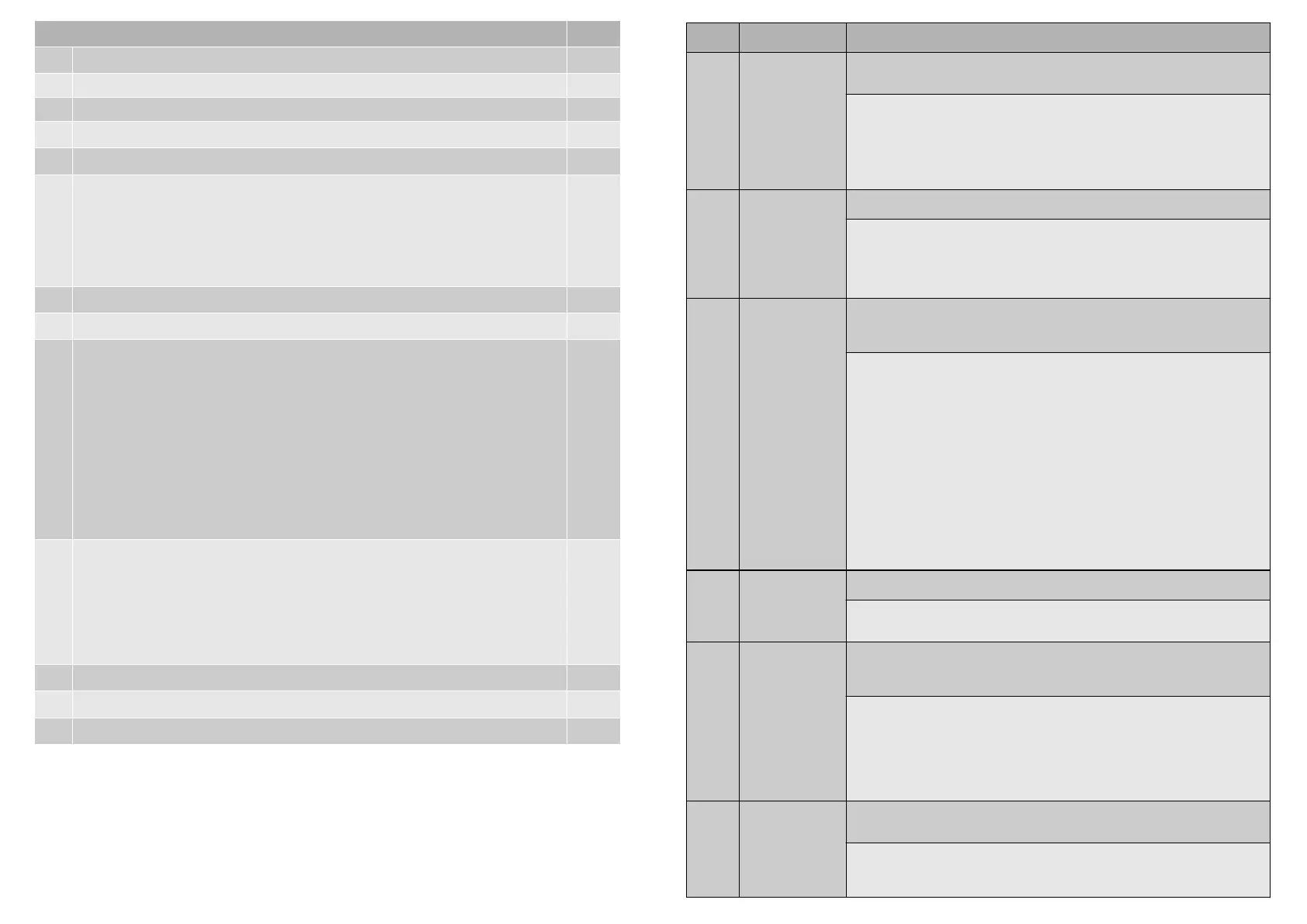

ERROR

CODE

MEANING CAUSE & REMEDY

bb

Beams Blocked

Cause:

The infrared beam between the two Safety Beam sensors are blocked, indicang

an obstrucon or the baeries in the transmier beam are low.

Remedy:

Remove anything that may be obstrucng the doorway.

If there is no obstrucon, check that the Beam’s wiring is correct.

Test the beams to ensure they are in fact operaonal.

Check for possible ant infestaons in the beams.

If no beams have been installed, ensure that the beams seng in the operator

menu is set to bn.

LO

Lockout

Cause:

The operator has been placed in ‘Holiday Lockout’ mode.

Remedy:

To deacvate Holiday Lockout, press the buon on the remote that was assigned

to acvate Holiday Lockout.

To prevent accidental acvaon, is it recommended that the funcon is assigned

to a remote/s by pressing two of the remote buons simultaneously. This will

reduce the risk of accidentally acvang the Lockout funcon.

ES

Encoder Stop

(Fault/Obstrucon)

Cause:

The operator has ‘stalled’. This could be as a result of the door hing an

obstrucon, the limits being set incorrectly, an incorrect force limit seng or a

faulty Encoder.

Remedy:

1) Remove any physical obstrucon. If no obstrucon....2.

2) Check that the limits have been set correctly and that the door is not stopping

hard against the floor or any other physical stop. If the limits are set

correctly.....3.

3) Check the Door Balance. To do this, disengage the door from the Drive

Channel via the Manual Release Mechanism. Be sure to support the door

before doing so to ensure that the door does not drop aer being released.

Manually open and close the door. The door should open and close easily,

requiring the same amount of force in both direcons. If the door is difficult to

move in either or both direcons, and the open and closing forces are not

within the operang parameters, the door will need to be balanced and

serviced. If the Door Balance is correct.....4.

4) The Force Level sengs on the Control Board may need to be adjusted. This

may happen if the door is ageing.

5) If all the previous checks are in order the Encoder may be faulty and the

garage operator will need to be serviced.

23

Er

Error Programming

Remote

Cause:

All 64 remote slots are occupied.

Remedy:

No further remotes can be programmed to the controller. In order to add new

remotes it will be necessary to delete some to make space.

HL

Heavy Load

Cause:

The operator has detected that the liing force is greater than the allowed

maximum. This could be as a result of an increase in the door’s fricon, incorrect

door specs or possibly a broken door spring.

Remedy:

Cauon: This error message indicates that the door is too heavy and that the

operator is unable to li it. Disengaging the the door from the Drive Channel via

the Manual Release Mechanism could result in the door dropping fast and could

cause damage or injury!

Disengage the door slowly and with great cauon. Manually open and closed the

door to establish the weight. If it is difficult to li, the door will need to be

repaired before reconnecng it to the operator.

Cb

Check Balance

Cause:

The door has gone out of balance, usually as a result of either one or both of the

door torsion springs being broken.

Remedy:

Disconnect the door from the operator and open and close it manually. If moving

the door in one direcon is more difficult than the other direcon then the door

will need to be repaired before reconnecng it to the operator.

Loading...

Loading...