Vehicle Systems Disassembly & Assembly

8.

In case of standard and full free mast, inner lower

bearings can be easily extruded by pulling down

the inner mast from the bottom of staionary mast.

If intermediate mast is stuck and do not move

rolling up and down, there might be excessive

shim. Pull out the intermediate mast from the

stationary mast and remove shim 0.5 mm to both

intermediate lower bearings. Repeat same

procedure of aboves until properly shimmed.

There is to be contact zero clearance (C) between

intermediate lower bearings and stationary

channel at approximately 475 mm (18.7 in)

channel lap.

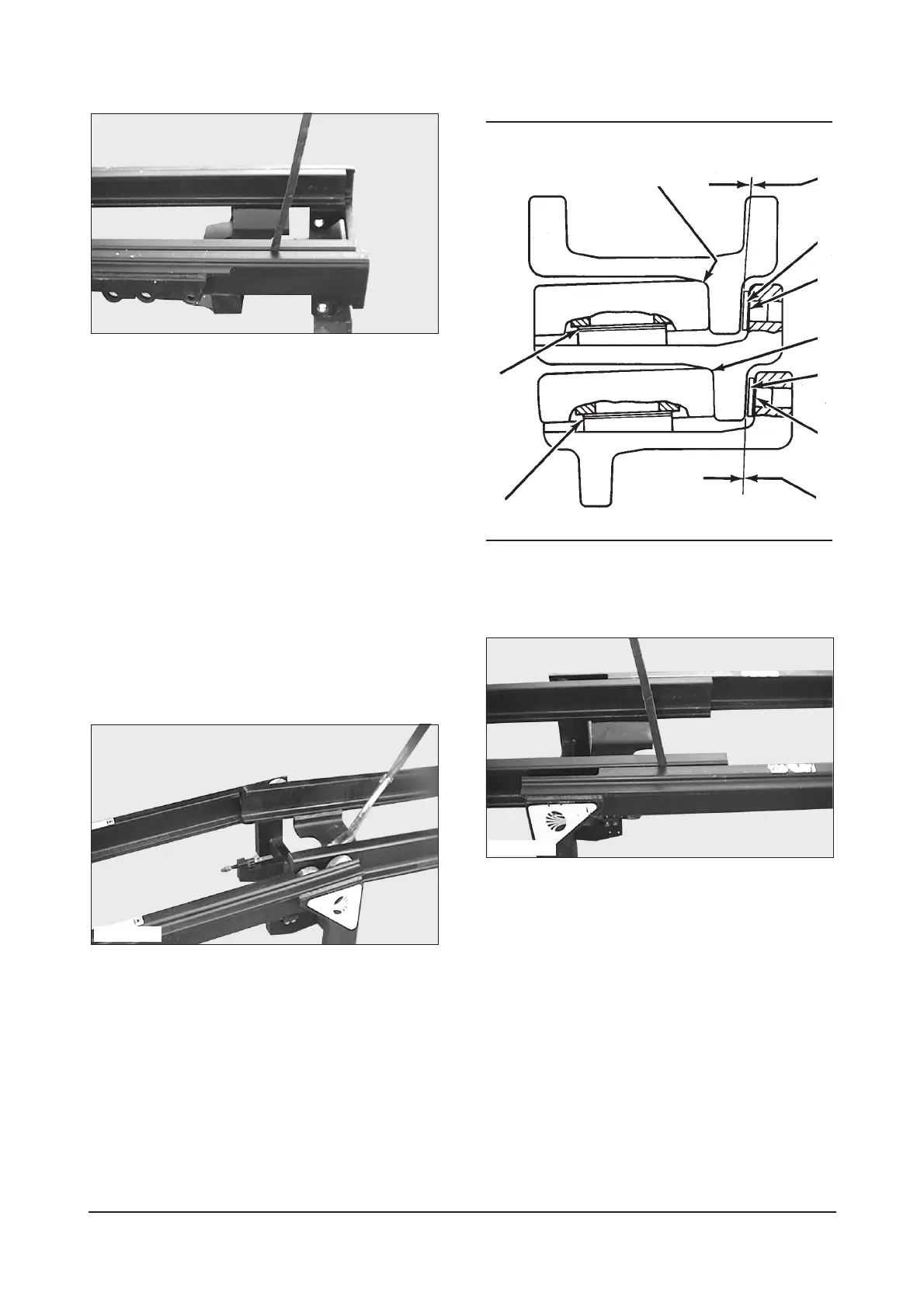

B. Upper Bearing Adjustment of Stationary

Mast

9.

Lifting by crane, and pull out intermediate mast

from stationary mast. Install 1 mm shim to each

bearing of stationary mast upper basically. Bearing

should be selected D581814 under size bearing.

Mast Adjustment Upper Bearings

(D) Zero clearance. (E) 0.80 mm (.031 in) Clearance maximum.

(F) Zero clearance. (7) Pads. (8) Shims. (9) Shims. (10) Shims.

10. Make sure whether stationary mast upper

bearings are properly shimmed by rolling up and

down and moving intermediate mast to right and

left. If clearance between both masts can be

detected, pull out the intermediate mast from the

stationary mast with crane and add shim 0.5 mm

or 1 mm to both stationary upper bearings.

20

IDCD039P

IDCD033P

IDCD038P

9

10

E

8

7

F

8

7

ED

IDCS124S

Loading...

Loading...