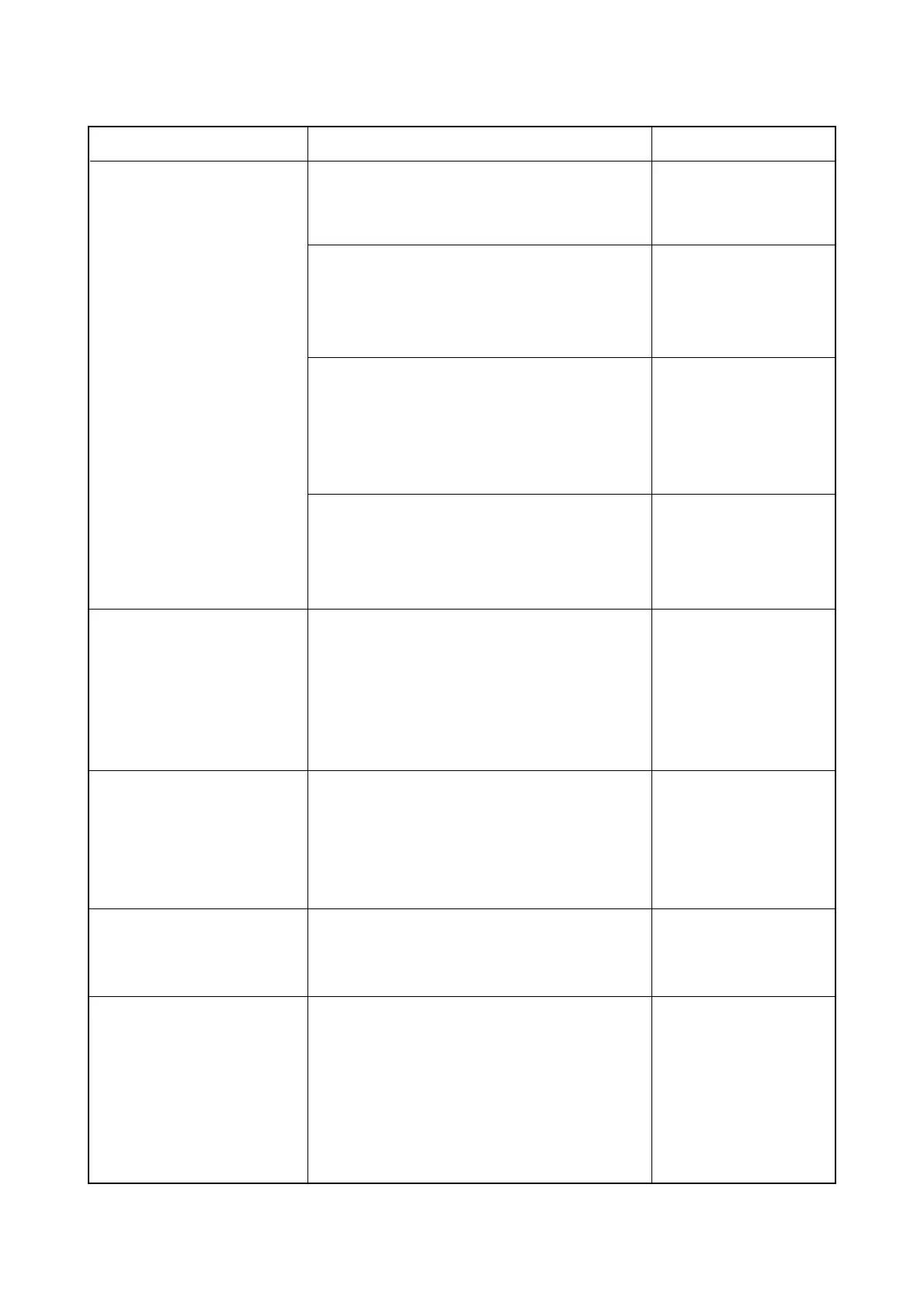

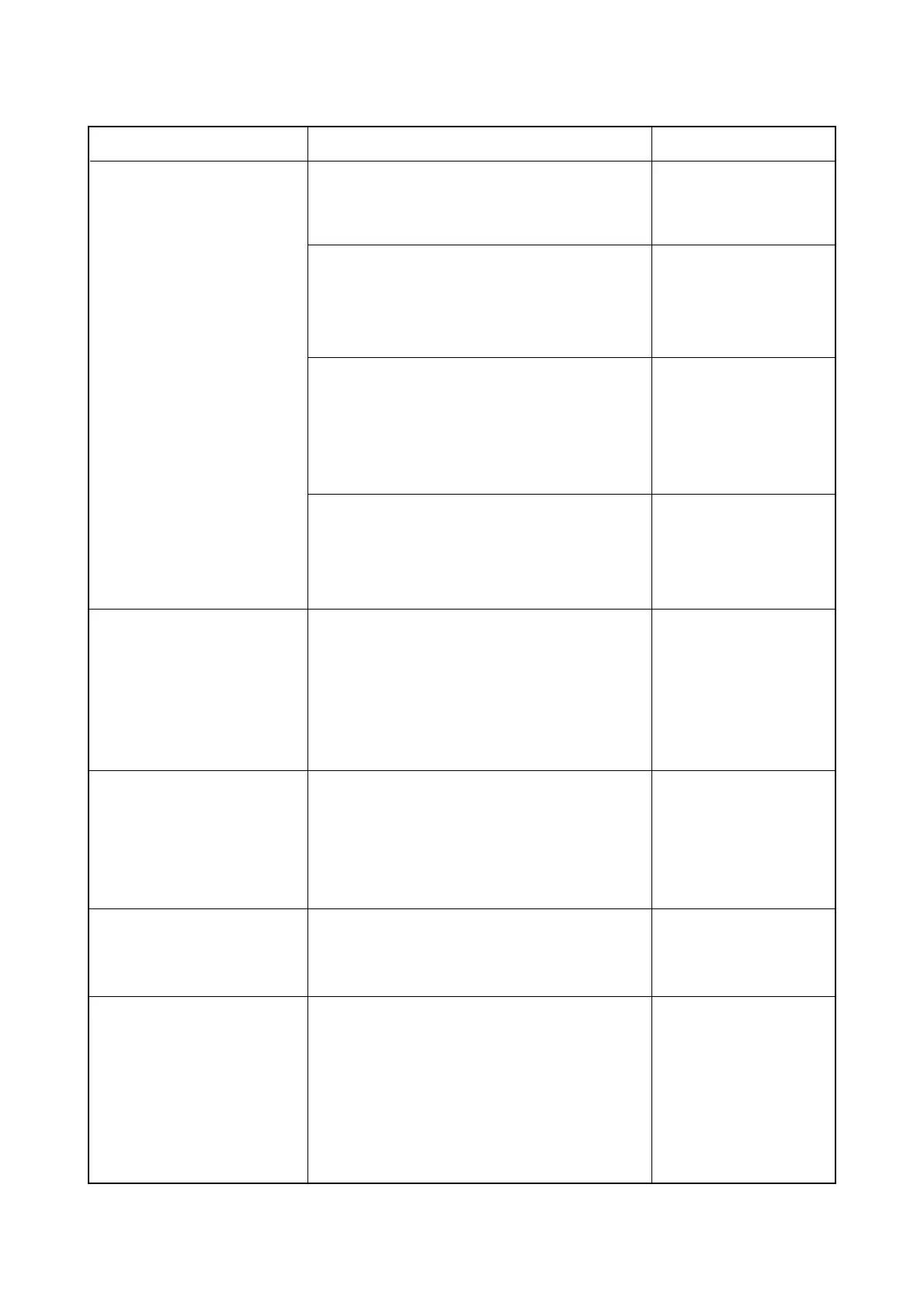

4.3.6. Diagnostics and troubleshooting

Complaints Possible causes Corrections

1. Engine won’t start (1) Fuel pipes clogged or air into pipe line Correct

1) Fuel not being pumped (2) Feed pump valve defective Replace

out from feed pump (3) Feed pump piston or push rod sticking Disassemble, correct

2) Fuel not being injected (1) Fuel filter element restricted Clean

from injection pump (2) Air in fuel filter or injection pump Bleed

(3) Plunger and/or delivery valve sticking Disassemble, correct

or defective

3) Fuel injection timing (1) Injection pump not properly installed Check, correct

incorrect on pump bracket

(2) Injection pump tappet incorrectly Check, correct

adjusted

(3) Cams on cam shaft worn excessively Replace

4) Injection nozzles (1) Needle valves sticking Correct or replace

inoperative (2) Fuel leaking past clearance between Correct or replace

nozzle and needle valve

(3) Injection pressure incorrect Adjust

2. Engine starts but (1) Pipe from feed pump to injection pump Clean

stalls immediately clogged or filter clogged

(2) Air in fuel Bleed

(3) Feed pump delivery insufficient Disassemble, correct

(4) Fuel delivery insufficient due to clogging Replace breather

of fuel tank air breather

3. Engine lacks power (1) Plunger worn excessively Replace

(2) Injection timing incorrect Adjust

(3) Delivery valves defective Replace

(4) Nozzle leaks excessively Correct or replace

(5) Nozzle not working normally Disassemble, correct

4. Engine knocking (1) Injection timing too fast Adjust

(2) Nozzle injection pressure too high Adjust

(3) Nozzles not working normally Disassemble, correct

5. Engine knocks (1) Injection timing incorrect Adjust

seriously producing (2) Nozzle injection pressure too low Adjust

excessive exhaust (3) Nozzle spring broken Replace

smoke (4) Nozzles not working normally Replace

(5) Plungers worn excessively Adjust

(6) Delivery valves seat defective Replace

(7) Supply of fuel excessively Check feed pump

- 133 -

Loading...

Loading...