3) Inspection and correction of valve seat

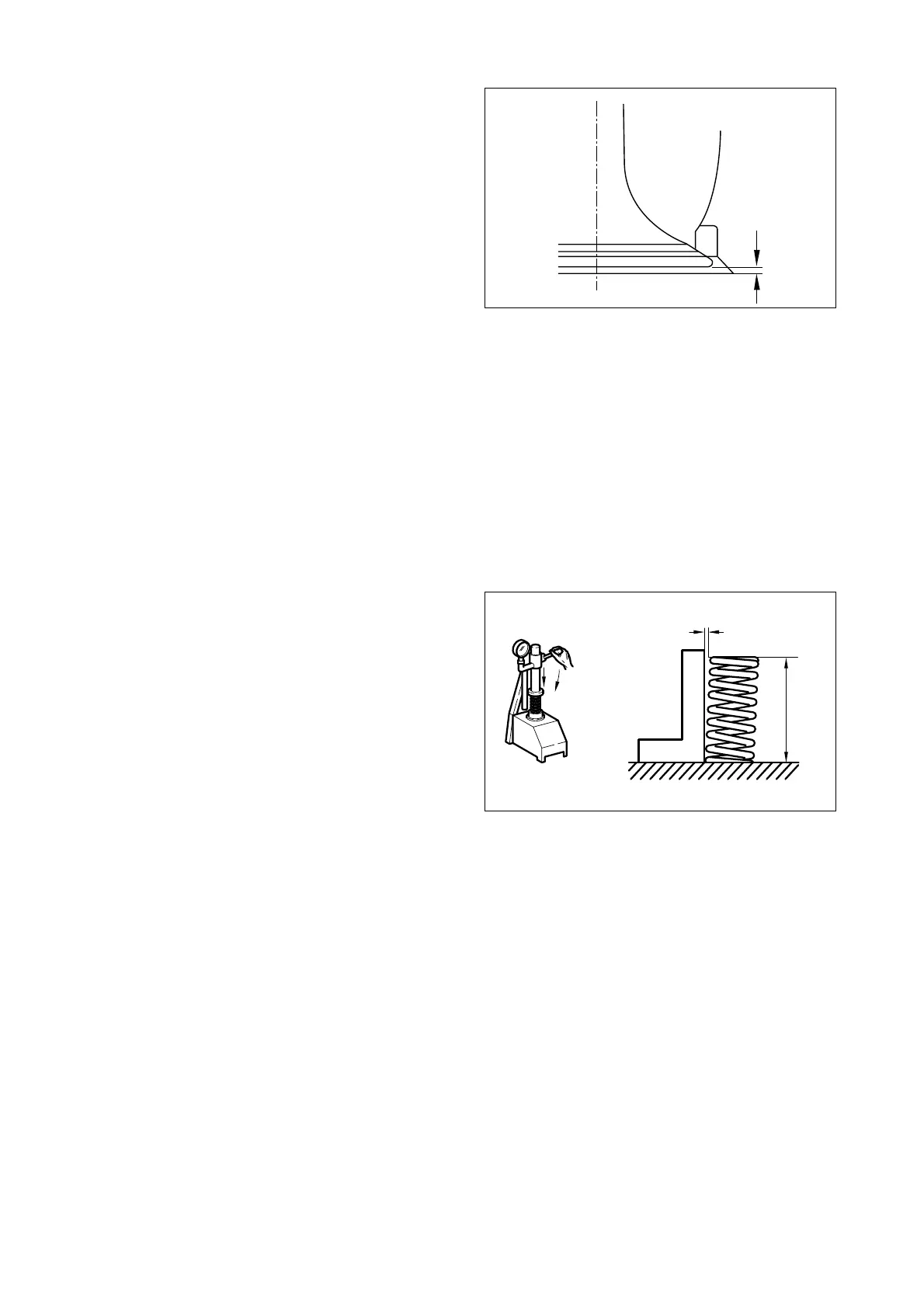

(1) Measure the contacting face

between the intake valve seat and

exhaust valve seat for valve seat

wear, and replace if the measured

value exceeds the specified limit.

(2) Install the valve into the valve seat on

the cylinder head, and check the

amount of depression of the valve

from the lower portion of the cylinder

head using a dial gauge.

If the amount of depression is beyond the specified limit, replace the valve seat.

(3) For removal of the valve seat, apply arc welding work to two points of valve seat insert,

and pull out valve seat insert with inner extractor.

(4) Undercool a new valve seat with dry ice for about 2 hours and press the valve seat insert

into position in the cylinder head using a special tool(bench press).

(5) Apply valve lapping compound to the valve head seating face on the valve seat and lap

the valve seat by turning it until it is seated in position, then wipe out the lapping com-

pound.

- 51 -

EQM3049I

4) Inspection and correction of valve spring

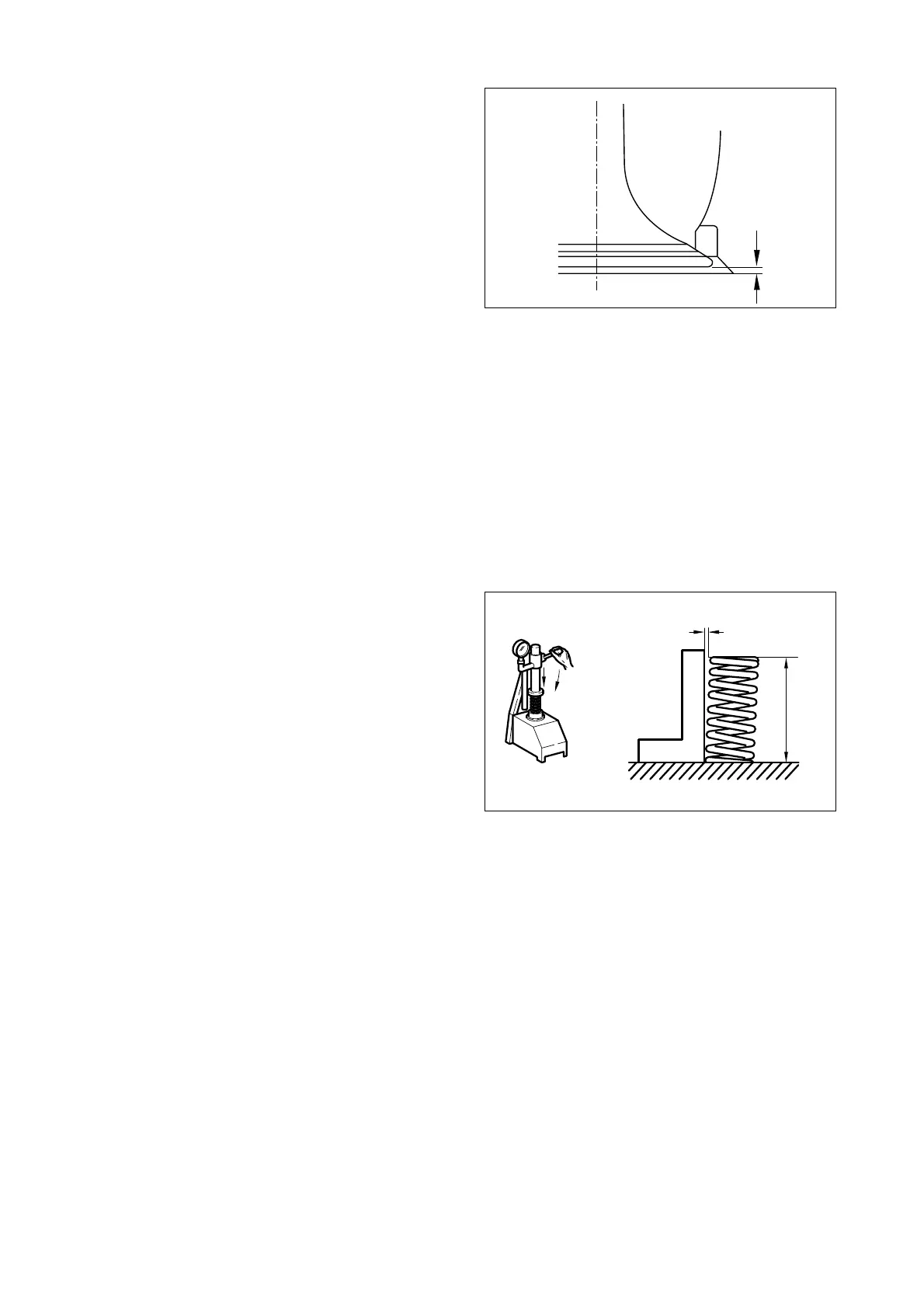

(1) Visually check the exterior of the

valve springs for damage, and

replace if necessary.

(2) Measure free length and spring ten-

sion with a valve spring tester.

(3) Measure the spring inclination with a

square.

(4) Compare the measured value with

the standard value to determine

whether to replace or repair.

Loading...

Loading...