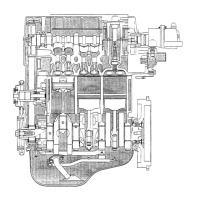

ENGINE MECHANICALS

'.

Remove the cylinder block from the

SST

INSPECTION

1.

Checking of cylinder block

(1) Check the cylinder block for damage or cracks.

(2)

Check the cylinder head gasket surface for distortion.

NOTE:

Perform the measurement

in

six directions.

Maximum distortion limit:

0.1

mm

(0.0039

inch)

[CB-23

engine only]

If the distortion exceeds the maximum distortion limit,

recondition the surface. However, this reconditioning

should not be performed beyond the grinding limit of

0.3 mm (0.01

2

inch).

Furthermore, make sure that the width between the

cylinder head gasket contact surface and the oil pan

attaching surface is at least 200.55 mm (7.896 inches).

(3)

Measure the cylinder bore diameters.

Measure the bore diameter of each cylinder. The

measilrement should be made at six points.

@)

Ensure that the difference between the maximum and

minimum bore diameters of each cylinder is within

0.1 mm (0.039 inch).

NOTE:

The measurement results should be recorded.

@ If the difference between the maximum and minimum

values exceeds the specified value (0.1 mm or 0.039

inch), perform boring and honing for the cylinder.

Specified cylinder bore diameter after honing

When repaire standard pis-

76.00

-

76.03

mm

ton is used:

(2.992

-

2.993 inch)

When

01s

0.25 piston is 76.25

-

76.28

mm

useu: (3.002

-

3.003 inches)

I

76.50

-

76.53

mm

When

OiS

0.50 piston is

1

used:

1

(3.012

-

3.013 inches)

Measured in six

directions

I

I

Fig.

5-244

WM-05285

I

I

Fig. 5-245

WM-05286

A@

10

mm

(0

39

~nch)

Center

1%

,I0

mm

(0.39

~nch)

Fig. 5-246

'~~-0528i

Honing

an~le

35"

F

5"

Surface coarse degree

1.5

-

42

I

I

Fig. 5-247

WM-05288

Loading...

Loading...