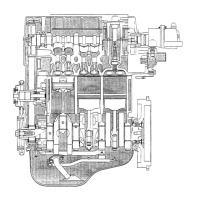

ENGINE MECHANICALS

@

After the cylinder block has been cleaned and checked, calculate the cylinder-to-piston clearanc:

At this calculation, use the minimum measurement value as the cylinder bore diameter of each

cylinder.

Cylinder-to-piston clearance:

0.03

-

0.12 mm (0.0012

-

0.0047 inch)

NOTE:

If the calculated clearance exceeds the specified value, perform boring and honing, referring to the

specifications in

@.

However, if the oversize pistons have been installed and the cylinder-to-piston

clearance has exceeded the specified value, replace the cylinder block and pistons.

L

I

Fig.

5-249

Wu-05291

a

Assemble the spring to the main body of the

SST.

@

Attach the smaller bar on the spring. While pushing

the lever into the body, install the fitting piece to the

main body, with the surface having a cut-out section

facing upward. Then, secure it with the attaching

screw.

@

Place the piston on the fitting piece, aligning the

cut-out sections.

09221

-2501

8-000

@

Install the longer lever into the piston hole.

@

Press off the piston pin, using a press.

NOTE:

Fig.

5-250

WM-05292

Arrange the disassembled pistons and piston pins in order

so that their installation positions

riiay be known readily.

'NM-05289

2.

Checking of piston and pision rings

(1)

Remove the piston rings No.1 and No.2, using a

commercially-avaiiable piston ring expander or the

like.

NOTE:

(iJ

Arrange the removed piston rings in order so that their

installation positions may be known readily.

@ Do not expand the piston ring unnecessarily beyond

the required extent.

Fig.

5-248

WM-05200

(2)

Remove the oil ring

by

hand.

NOTE:

@

Arrange the removed oil rings in order so that their

installation positions may

be

known readily.

@

Do not expand the oil ring unnecessarily beyond the

required extent.

(3)

Disassemble the piston pin

from

the piston, using the

following

SST.

SST: 09221 -2501 8-000

7

Main

body

Loading...

Loading...