-1-

Thank you for purchasing DAIHEN CO

2

/MAG welding torch.

Before use, read this instruction manual thoroughly to use the product correctly.

[No te] 1. The contents in this instruction manual are subject to change without prior notice.

2. We have carefully written the standard specifications to eliminate as many errors as possible.

Even if any errors are found in the contents, we are not responsible for any damage resulting

from those errors.

3. No part of this instruction manual may be reproduced or stored in any form without the express

written permission.

1. Specifications

This is the “CO

2

/MAG welding torch” to be used for CO

2

/MAG welding.

The specifications are shown in Table 1.1. (Refer to Fig.1.1 - 1.4 for the outline drawing.)

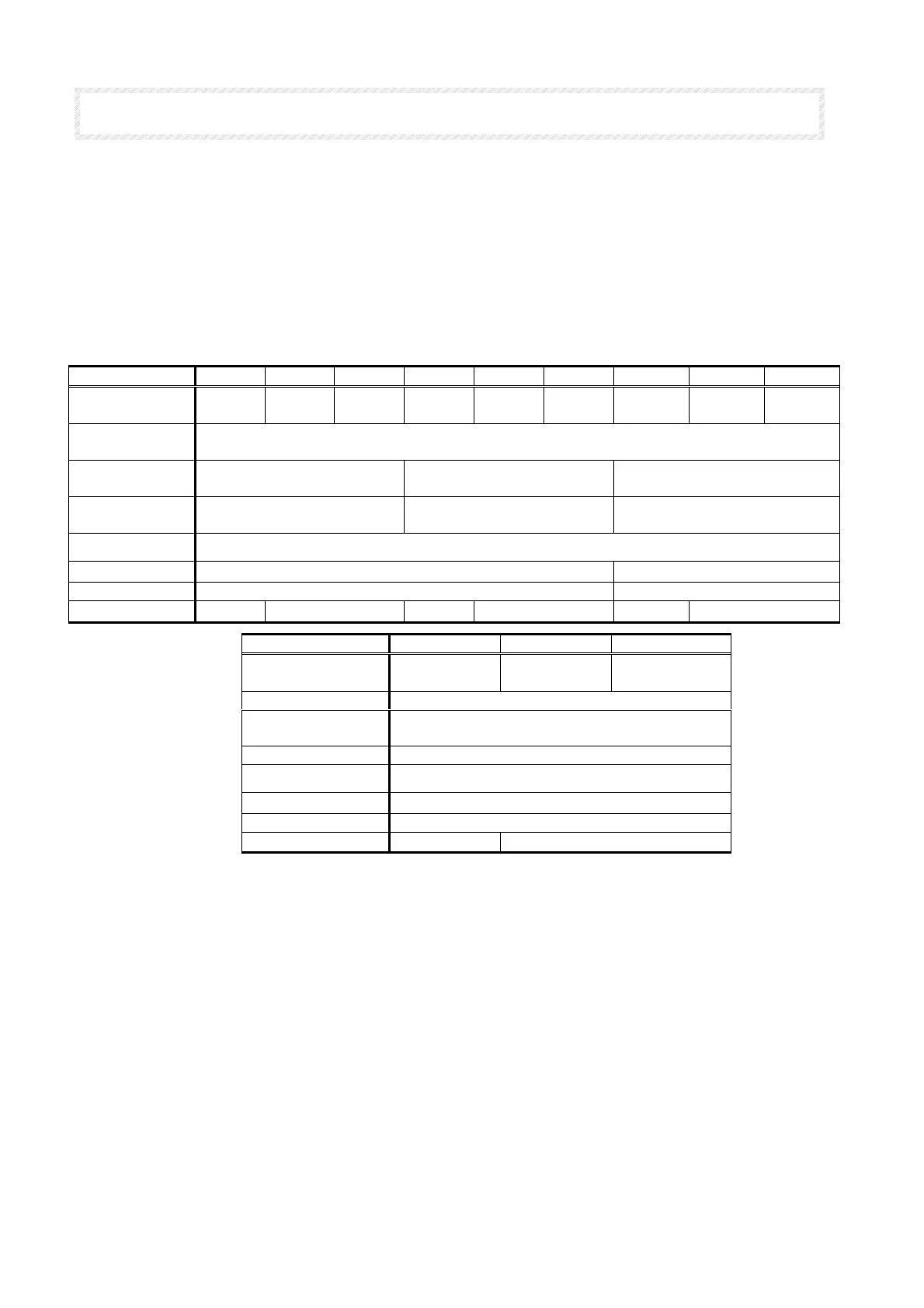

Table 1.1 Specifications of welding torch

Model

RT3500S

RT3500H

RT3500L

RT5000S

RT5000H

RT5000L

RTW5000S

RTW5000H

RTW5000L

Torch type Straight

Curved

(45°)

Curved

(31°)

Straight

Curved

(45°)

Curved

(31°)

Straight

Curved

(45°)

Curved

(31°)

Welding

process

CO

2

(MAG)

Max. operating

current

350A(350A) 500A(350A) 500A(400A)

Rated duty

cycle

80% (60%) 50% (70%) 70% (60%)

Wire type

Solid wire, Flux cored wire

Applicable wire

(φ

0.8

)(φ

0.9

)(φ

1.0

)φ

1.2

(φ

1.4

)(φ

1.6

)

(

φ

1.2) (

φ

1.4

)

φ

1.6

Cooling system Air cooling Liquid cooling

Shock sensor

SSV

SSV、SSB

SSV

SSV、SSB

SSV

SSV、SSB

Note) 1. While using RTW5000S, RTW5000H and RTW5000L, are sure that DAIHEN coolant liquid is being

supplied with the water tank (PU-301).

2. The maximum operating current and rated duty cycle are different between CO

2

and MAG welding system.

3. Shock sensor function

Arc welding robots may cause the welding torch to come into contact with workpiece or jig, thus resulting in the

deformation of the welding torch or damage to the robot itself. To prevent such problem, this welding torch

incorporates the shock sensor function that outputs an external force detection signal the instant when the nozzle

portion gets displaced to immediately stop the robot if external force larger than that specified is applied to the torch

tip portion (nozzle portion). This function is incorporated on the assumption that the welding torch comes into

contact with workpiece or jig during robot teaching. Contact of the welding torch with it while in automatic operation

may cause damage to the robot or the torch.

The shock sensor function does not provide any guarantees against the accuracy of aiming point of the torch tip

portion. After the shock sensor gets activated, ensure the aiming point. (For detail, refer to information in Section

5.2.)

4. None of RZ3500S or RZ3500L or RZ3500H accepts stainless wire.

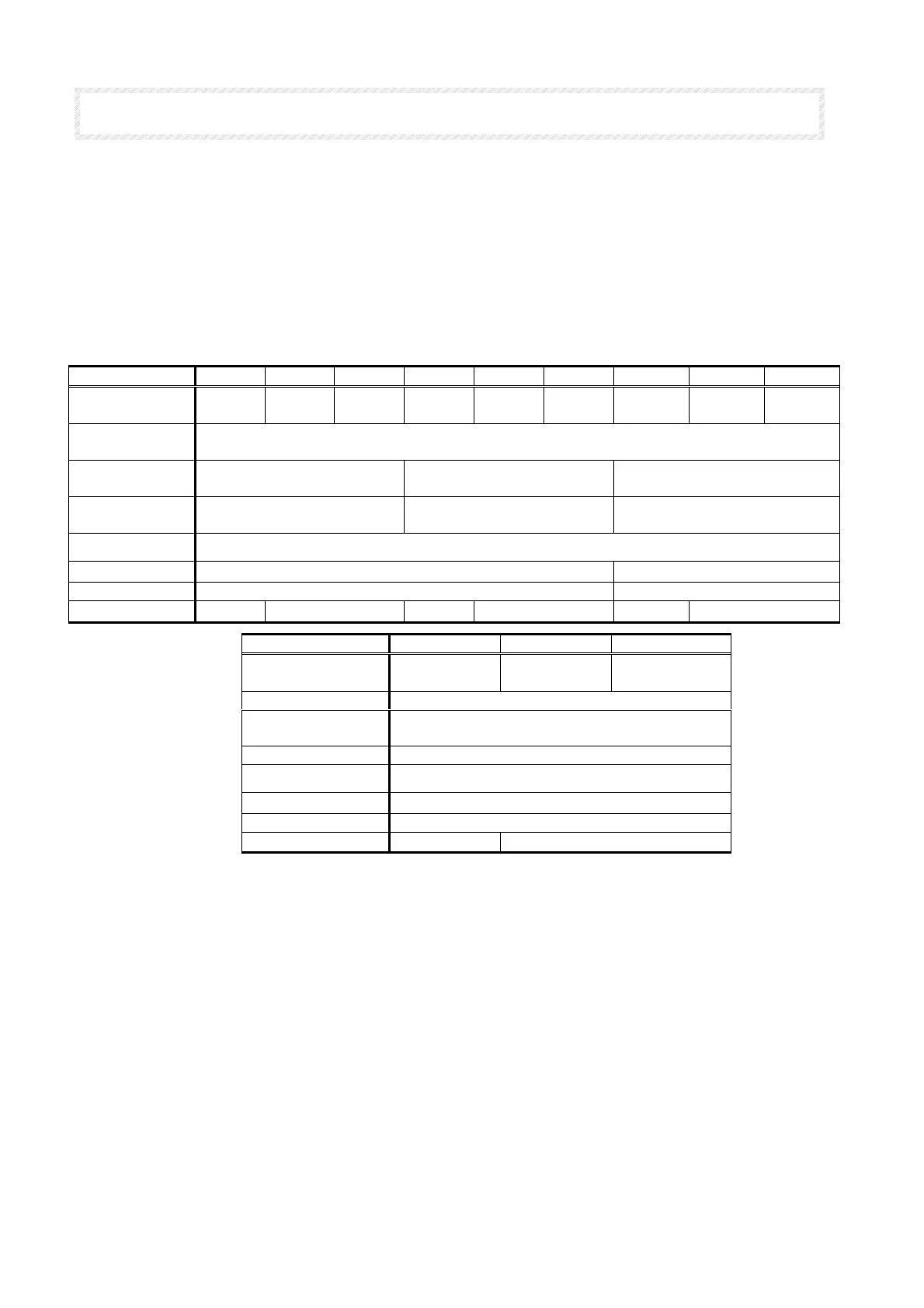

Model

RZ3500S RZ3500H RZ350 0 L

Torch type Straight

Curved

(45°)

Curved

(31°)

Welding process CO

2

(MAG)

Max. operating

current

350A(350A)

Rated duty cycle 80% (60%)

Wire type

Solid wire, Flux cored wire

Applicable wire

(φ

0.9

)(φ

1.0

)

φ

1.2

(φ

1.4

)(φ

1.6

)

Cooling system

Air cooling

Shock sensor

SSV SSV、SSB

Loading...

Loading...