INSTALLATION INSTRUCTIONS

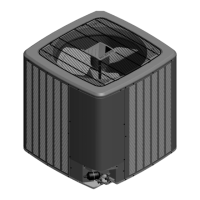

DX14XA SERIES

CONDENSING UNIT

IOD-1057A

09/2022

© 2022

www.daikincomfort.com

Important Safety Instructions

WARNING

WARNING

HIGH VOLTAGE

WARNING

Shipping Inspection

accept claims from dealers for transportation damage or

Codes & Regulations

This product is designed and manufactured to comply

for Daikin

residential or commercial products menu and then select

The United States Environmental Protection Agency

follow these regulations may harm the environment

must

NOTE: Installation of unmatched systems is strongly

NOTE: