English 7

Use “ Table 2 ” as a reference if a torque wrench is not available.

Once work is complete, make sure there is no gas leaking. As

the flare nut is tightened with the wrench, the torque will sud-

denly increase. From that position, tighten the nut to the angle

shown on “ Table 2 ”.

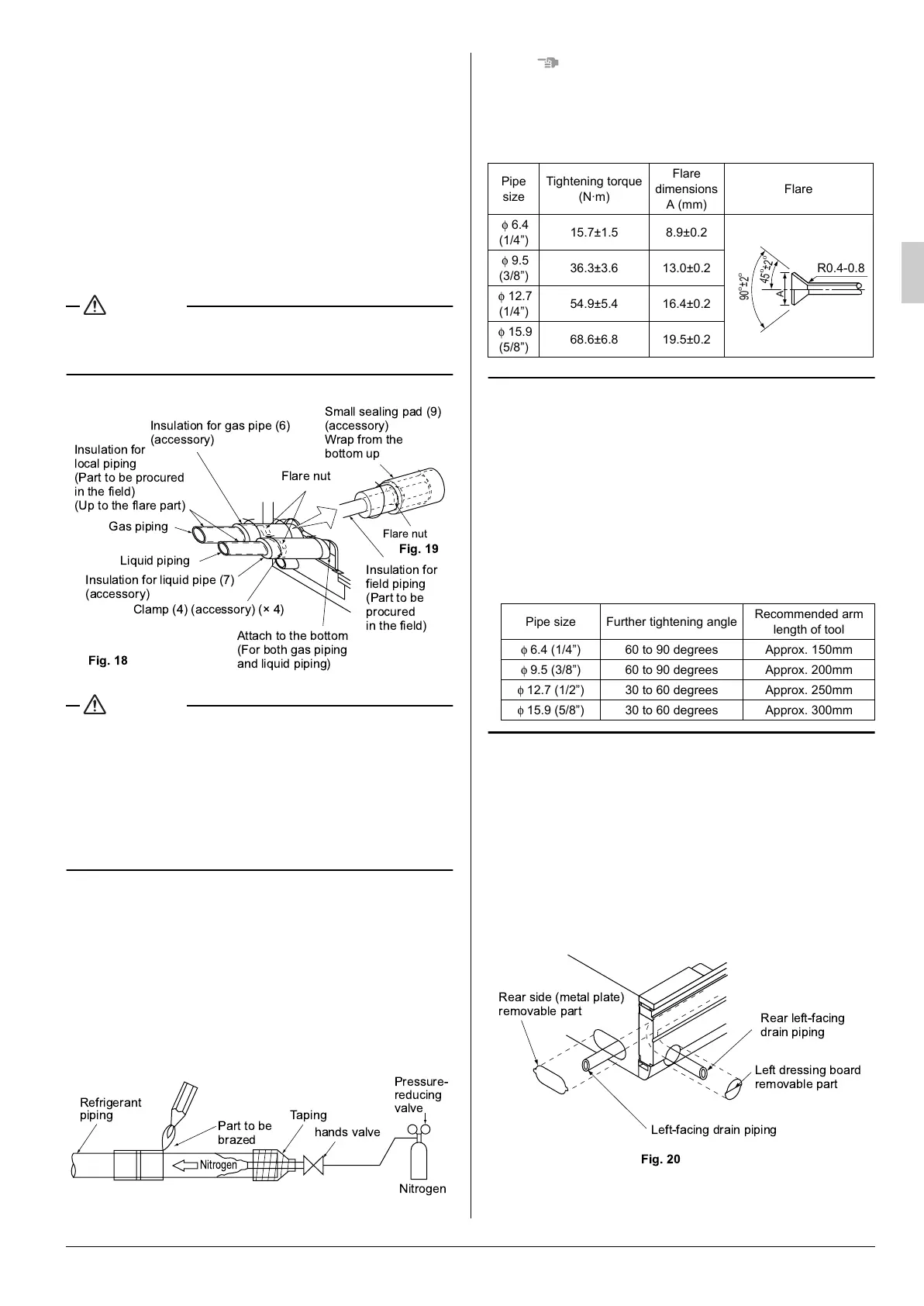

• Make absolutely sure to execute heat insulation works on the

pipe-connecting section after checking gas leakage by thor-

oughly studying the following figure and using the attached

heat insulating materials for fitting (6) and (7). (Fasten both

ends with the clamps (4) (accessory).)

(Refer to Fig. 18)

• Wrap the sealing pad (9) (accessory) only around the insula-

tion for the joints on the gas piping side.

(Refer to Fig. 19)

CAUTION

Be sure to insulate any field piping all the way to the piping

connection inside the unit. Any exposed piping may cause

condensation or burns if touched.

CAUTION

CAUTION TO BE TAKEN WHEN BRAZING REFRIGER-

ANT PIPING

Do not use flux when brazing refrigerant piping. Therefore, use

the phosphor copper brazing filler metal (BCuP-2: JIS Z 3264/

B-Cu93P-710/795: ISO 3677) which does not require flux.

(Flux has extremely harmful influence on refrigerant piping

systems. For instance, if the chlorine based flux is used, it will

cause pipe corrosion or, in particular, if the flux contains fluo-

rine, it will damage the refrigerant oil.)

• Before brazing local refrigerant piping, nitrogen gas shall be

blown through the piping to expel air from the piping.

If your brazing is done without nitrogen gas blowing, a large

amount of oxide film develops inside the piping, and could

cause system malfunction.

• When brazing the refrigerant piping, only begin brazing after

having carried out nitrogen substitution or while inserting

nitrogen into the refrigerant piping. Once this is done, con-

nect the indoor unit with a flared or a flanged connection.

• Nitrogen should be set to 0.02 MPa with a pressure-reducing

valve if brazing while inserting nitrogen into the piping.

NOTENOTENOTENOTE

The flare nuts used must be those included with the main

body.

• Refer to Table 1 for tightening torque.

Tabl e 1

Not recommendable but in case of emergency

You must use a torque wrench but if you are obliged to

install the unit without a torque wrench, you may follow the

installation method mentioned below.

After the work is finished, make sure to check that

there is no gas leak.

When you keep on tightening the flare nut with a spanner,

there is a point where the tightening torque suddenly

increases. From that position, further tighten the flare nut

the angle shown below:

Tabl e 2

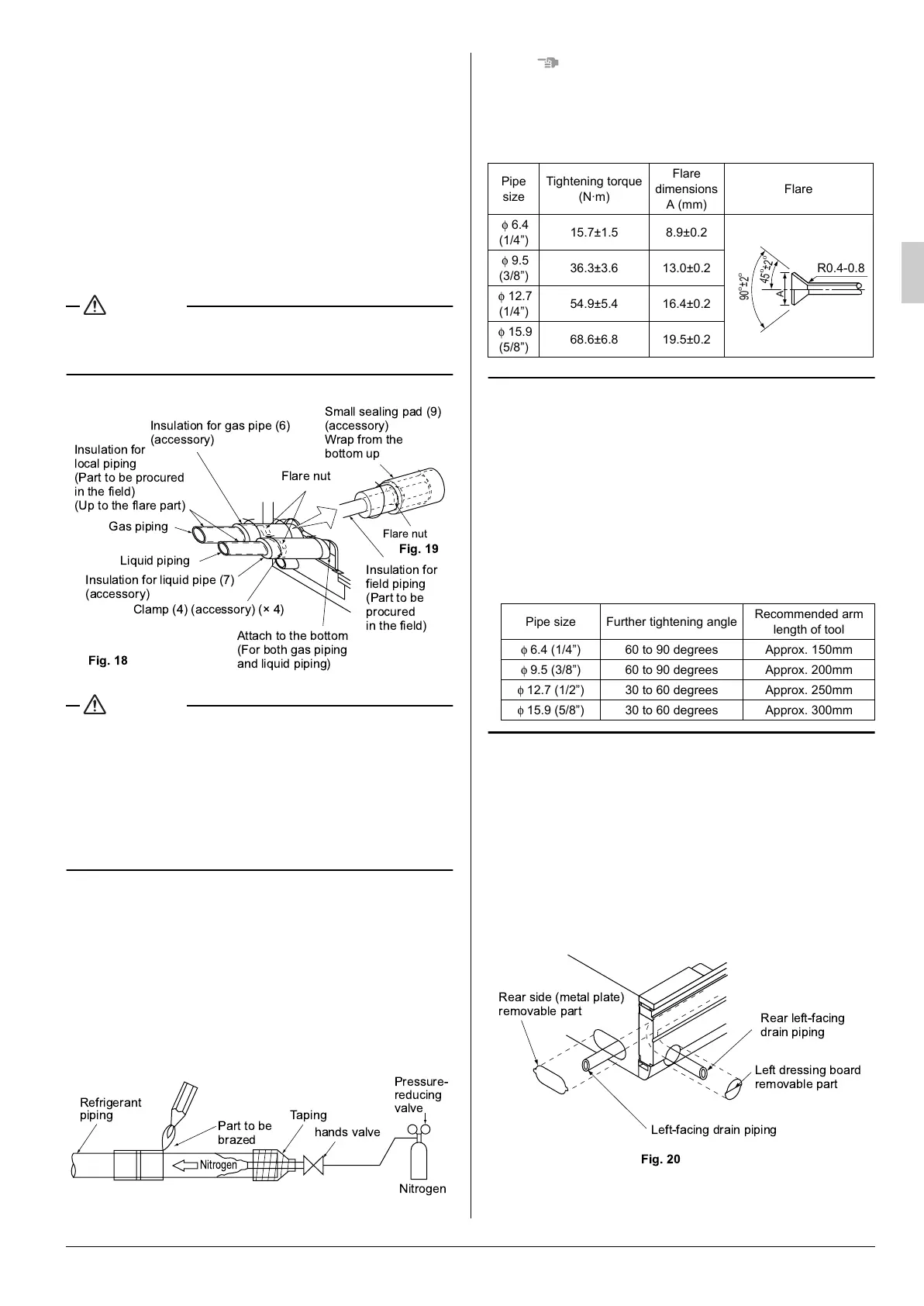

7. DRAIN PIPING WORK

Rig the drain pipe as shown below and take measures against

condensation. Improperly rigged piping could lead to leaks and

eventually wet furniture and belongings.

(1) Carry out the drain piping

• For drain work, rig the pipes so that they drain reliably.

• The drain pipe outlet direction can be chosen from the

right rear, right, left rear, and left. Refer to “REFRIGER-

ANT PIPING WORK” for right rear and right direction,

and refer to Fig. 20 for left rear and left direction.

!

" # $ #

%

Fig. 18

Fig. 19

Pipe

size

Tightening torque

(N·m)

Flare

dimensions

A (mm)

Flare

φ 6.4

(1/4”)

15.7±1.5 8.9±0.2

φ 9.5

(3/8”)

36.3±3.6 13.0±0.2

φ 12.7

(1/4”)

54.9±5.4 16.4±0.2

φ 15.9

(5/8”)

68.6±6.8 19.5±0.2

Pipe size Further tightening angle

Recommended arm

length of tool

φ 6.4 (1/4”) 60 to 90 degrees Approx. 150mm

φ 9.5 (3/8”) 60 to 90 degrees Approx. 200mm

φ 12.7 (1/2”) 30 to 60 degrees Approx. 250mm

φ 15.9 (5/8”) 30 to 60 degrees Approx. 300mm

A

45

0

±

2

0

R0.4-0.8

90

0

±

2

0

Rear side (metal plate)

removable part

Left-facing drain piping

Left dressing board

removable part

Rear left-facing

drain piping

Fig. 20

01_EN_3P172532-7B.fm Page 7 Wednesday, October 14, 2015 6:17 PM

Loading...

Loading...