LRYEQ16A7Y1 + LCBKQ3AV1(E)

CONVENI-PACK

4P448940-1A – 2016.07

Operation manual

16

2. Installation failure (Installation and environ-

mental problems)

• The unit is not installed on a stable horizontal

plane.

∗ The unit is not fixed securely.

• The environmental conditions of the place of

installation differ from normal atmospheric

conditions.

∗

Briny air environment, shore side, oil mist

environment, kitchen exhaust side, other cor-

rosive gas and adhesive mist environment.

• The place of installation had poor ventilation

and heat dissipation.

∗ The machine took in exhausted air again.

3. Work failure

• The interior of the piping was not vacuum

dried sufficiently.

∗ The clogging of the thin areas of the piping

caused by icing.

• The interior of the piping was not sufficiently

airtight.

∗ Leakage of refrigerant gas.

• The interior of the piping was contaminated

with foreign substance.

∗ The clogging of the thin areas of the piping.

• The unit was adversely affected by on-site

modification work.

∗

The use of the unit beyond the operating tem-

perature range as a result of on-site modifica-

tion.

• An accident resulted from the improper han-

dling of the unit under installation work.

∗ The loosening or wobbling of the outer panel

or broken or bent damage to the piping.

4. Operational failure

• Temperature settings for stored objects were

wrong.

∗ The storage of vegetables at temperatures

below 0°C.

• The periodical maintenance of the unit was

neglected.

∗ The clogging of the air heat exchanger, rust

generation from each part, gas leakage, and

icing of the indoor unit (showcase and unit

cooler).

5. Others

• Improvements recommended by our dealer in

advance were not accomplished.

∗ The simultaneous starting and stopping of a

number of units.

• Accidents were caused by natural disaster or

fire.

∗

Damage to electrical parts caused by lightning.

• There were other installation and operational

problems beyond common sense.

∗ The use of the unit without heat insulation

work on the piping.

• Work was conducted without keeping the fol-

lowing showcase restrictions.

<Showcase restrictions>

· The design pressure for the indoor unit is

2.5 MPa or more.

· The installation of the thermostatic expan-

sion valve and liquid supply solenoid valve

(both of which are for R410A) on a show-

case basis.

Thermal insulation of feeler tube of thermo-

static expansion valve must be thermal insu-

lated.

· Install showcases on the same floor if the show-

cases are connected to a single outdoor unit.

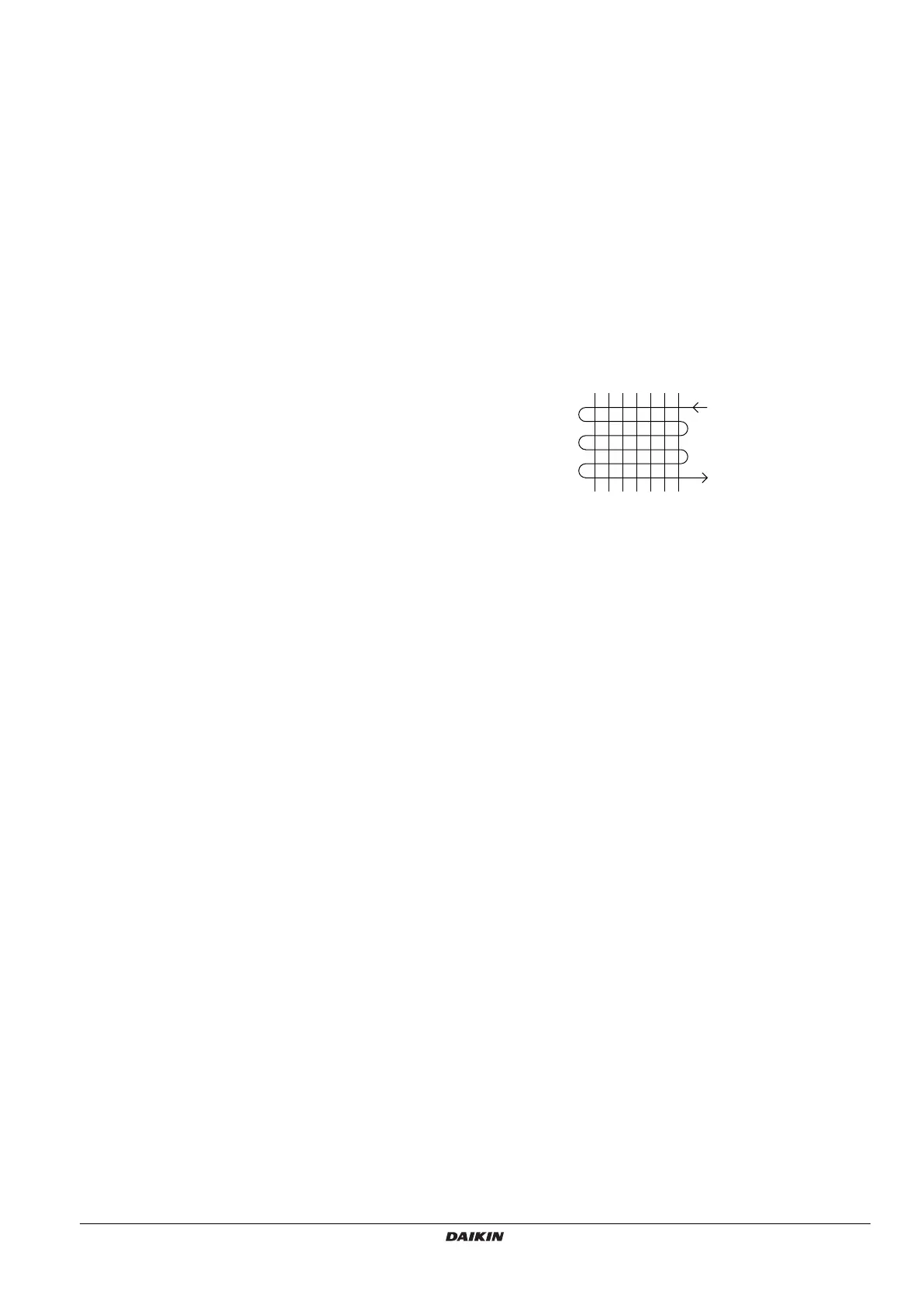

· Make sure that the outlet of piping used for

the heat exchanger is located downward (as

shown on the following figure).

Inlet

(upper side)

Outlet

(lower side)

Heat exchanger

4PEN448940-1A.book Page 16 Thursday, August 25, 2016 11:23 AM

Loading...

Loading...