Do you have a question about the Daikin VRV-WIV RWEYQ-T Series and is the answer not in the manual?

| Brand | Daikin |

|---|---|

| Model | VRV-WIV RWEYQ-T Series |

| Category | Air Conditioner |

| Language | English |

Explains symbols like DANGER, WARNING, CAUTION, NOTICE, INFORMATION.

Defines terms like Installation manual, Operation manual, Dealer, Installer, User, Service company.

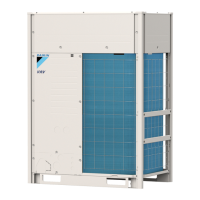

Introduces the VRV IV water-cooled units, their applications, and capacity.

Specifies temperature and humidity limits for safe and effective operation.

Refers to the Engineering Data Book for detailed specs.

Explains the model naming convention and codes.

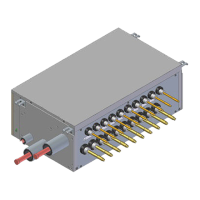

Lists required optional parts for outdoor unit installation.

Lists additional optional accessories like Cool/heat selector.

Instructions on how to open the unit front panel.

Lists and identifies major internal components.

Provides detailed physical dimensions of the unit.

Instructions on checking the unit for damage upon delivery.

Guidelines for safely handling and lifting the unit.

Instructions on removing packaging material safely.

Steps for physically mounting the unit on its base.

Cautions regarding R410A refrigerant and system tightness.

Specifies requirements for piping material and installation codes.

Specific warnings for connecting multiple outdoor units.

Safety advice for brazing refrigerant piping.

General guidance on connecting refrigerant piping.

Safety advice on operating stop valves.

Step-by-step guide for opening and closing stop valves.

Precautions for securing the stop valve cover.

Advice for safely using the service port.

Basic rules for leak testing and vacuum drying.

Detailed procedure for leak test and vacuum drying before powering up.

Advice on handling the heat exchanger during installation.

General safety warnings for electrical installations.

Basic principles for separating power and transmission wiring.

Rules for routing and connecting transmission wiring.

How to set interlock circuits and pump operation wiring.

Procedure for centralized interlock wiring for multiple units.

How to set the cooling/heating operation mode.

Steps for connecting power and transmission wiring within the unit.

How to access the logic board for settings.

Explains how to use push buttons for settings and operations.

Safety warnings and requirements before charging refrigerant.

Details about R410A refrigerant and GWP.

Formula and method for calculating extra refrigerant needed.

Checklist for critical checks before powering on the unit.

Explains how to monitor system status and adjust field settings.

Describes Automatic and Hi-sensible/economic operation methods.

Explains comfort settings like Powerful, Quick, Mild, Eco.

Safety checks and preparations before running the test operation.

Procedure for performing the system test operation.

Steps to take if the test operation fails.

General points on safety related to refrigerant leaks.

Explains calculating maximum allowable refrigerant concentration.

Importance of regular checks and inspections.

Safety warnings for performing service.

Procedure for vacuuming the system during service.

Lists physical and operational specs like capacity, weight, ranges.

Details electrical ratings, current, voltage, and wiring connections.

Explains basic operation modes and how to select them.

How to select modes using the unit's buttons.

How to select modes using a remote control switch.

Procedure for safely stopping the unit operation.

Steps to start the humidity reduction program.

Steps to stop the humidity reduction program.

Explains how air flow direction is controlled and adjusted.

Guidelines for managing heat source water quality.

Tasks for preparing the unit after a long period of inactivity.

Tasks for preparing the unit for storage.

Information about the product's warranty.

Recommendations for contacting service and maintenance.

Advice on regular maintenance and inspection contracts.

Lists recommended inspection and maintenance intervals.