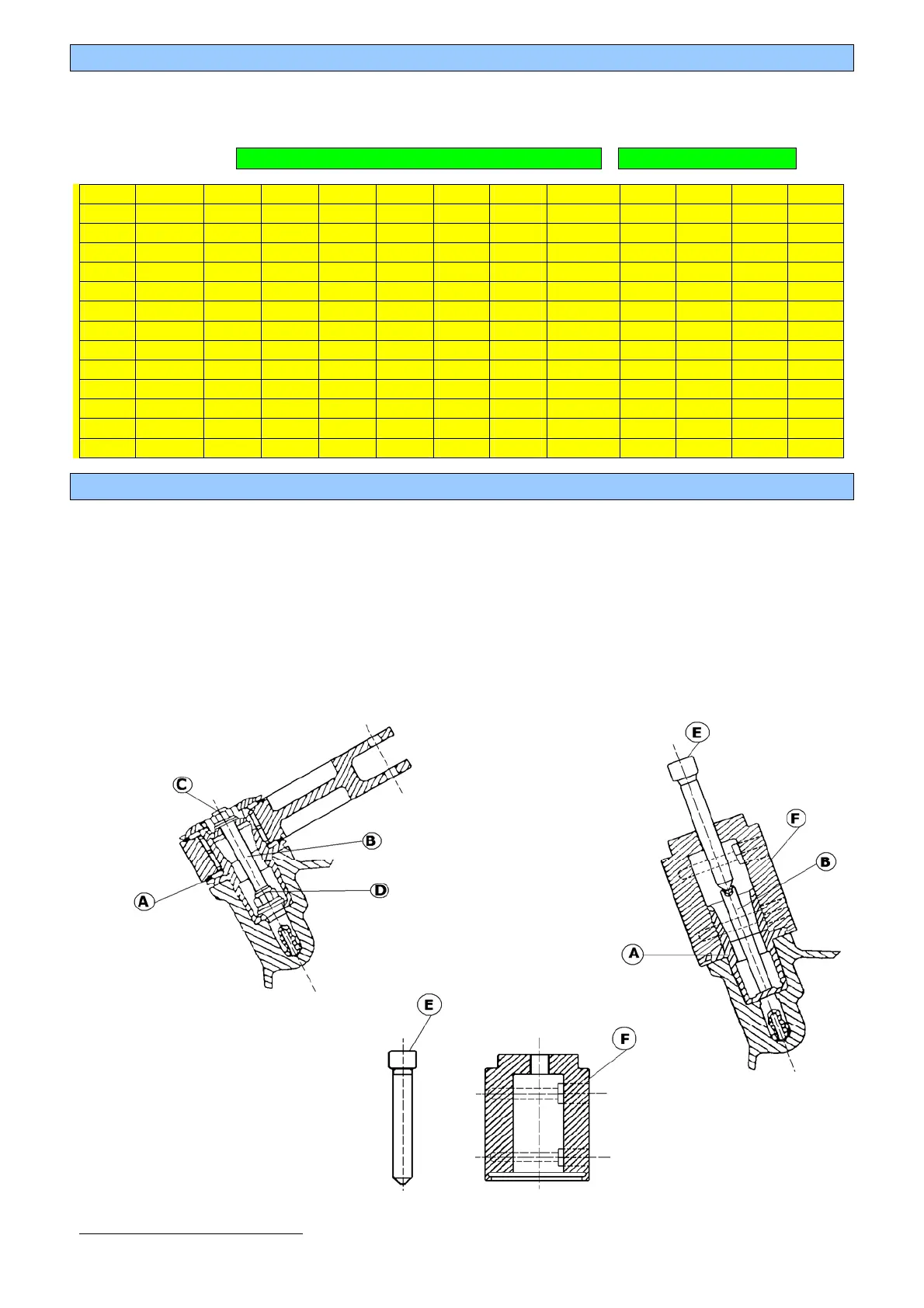

REAR ANTIROLL BAR STIFFNESS 14

F305 features a rear anti-roll bar with two adjustable blades, long 80mm.

Ø 40mm is the biggest possible RARB, Ø13mm is the softest RARB available.

The two digits in this table represent the blade positions: 1=full soft, 5=full stiff.

Stiffness in kg/mm. The hollow 30x3mm ARB is equal to std Ø26mm P1-P5 = P3-P3 = P2-P4

Ø 13 Ø 14 Ø 16 Ø 19 Ø 21 Ø 22 Ø 24 Ø26/30* Ø 28 Ø 30 Ø 35 Ø 40

P1-P1 15.7 19.9 29.4 44.6 53.8 57.8 65.0 70.6 75.1 78.7 84.5 87.7

1-2 15.8 20.2 30.0 45.9 55.7 60.1 67.9 74.1 79.0 83.0 89.5 93.0

2-2 16.0 20.4 30.6 47.4 57.8 62.5 71.0 77.8 83.3 87.7 95.0 99.0

1-3 16.3 20.8 31.5 49.5 61.1 66.3 76.0 83.8 90.2 95.5 104.1 108.9

2-3 16.4 21.1 32.1 51.2 63.6 69.3 80.0 88.7 95.8 101.8 111.7 117.3

1-4 16.7 21.5 33.1 53.7 67.6 74.1 86.3 96.6 105.1 112.3 124.5 131.4

1-5* 16.9 21.8 33.8 55.7 70.7 77.8 91.5 103.1 112.8 121.2 135.5 143.8

2-5 17.0 22.1 34.6 57.8 74.1 82.0 97.3 110.5 121.8 131.6 148.7 158.7

3-4 17.3 22.6 35.7 61.0 79.6 88.7 106.9 123.0 137.2 149.8 172.3 185.9

3-5 17.5 22.9 36.6 63.5 83.9 94.2 114.9 133.8 150.7 166.0 194.2 211.5

4-4 17.8 23.4 37.9 67.5 91.0 103.1 128.4 152.5 174.9 195.8 236.3 262.5

4-5 18.0 23.8 38.8 70.6 96.7 110.5 140.2 169.3 197.5 224.5 279.4 316.8

5-5 18.2 24.2 39.8 74.0 103.2 119.1 154.3 190.4 226.7 263.1 341.7 399.4

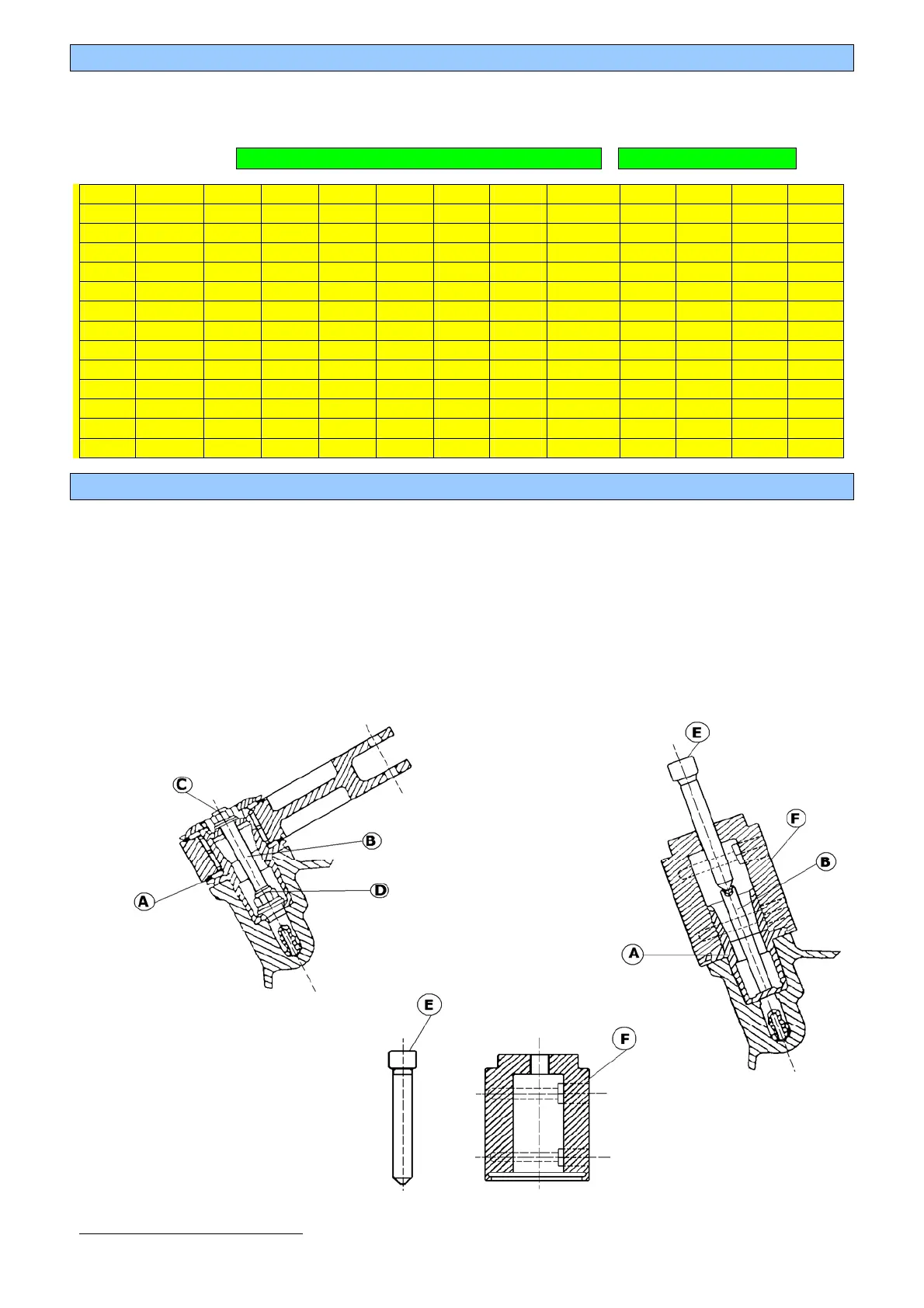

REAR SUSPENSION ROCKER REPLACEMENT

The rear rocker spins around a steel pivot (A) fitted into the gearbox case by the stud B,

fixed with LOCTITE 242

. The following procedure shows how to extract the rocker and the

pivot. Contact DALLARA customer’s service regarding the special tools E and F.

• Unscrew nut C and take off the cap and rocker. (Tightening torque for nut C is 3.5 Kgm)

• Unscrew nut D with 14mm tube spanner. (Tightening torque for nut D is 5.5 Kgm)

• Fit extractor F around pivot’s outer flange. By winding on bolt E the pivot will come out.

• Remove stud B with the proper tool. The stud is fitted with Loctite in its insert. When

removing the stud, heat the stud to about 140°C to break the Loctite.

Loading...

Loading...