CONTROL, FILLING AND OIL REPLACEMENT IN WHEEL

REDUCTION GEARS

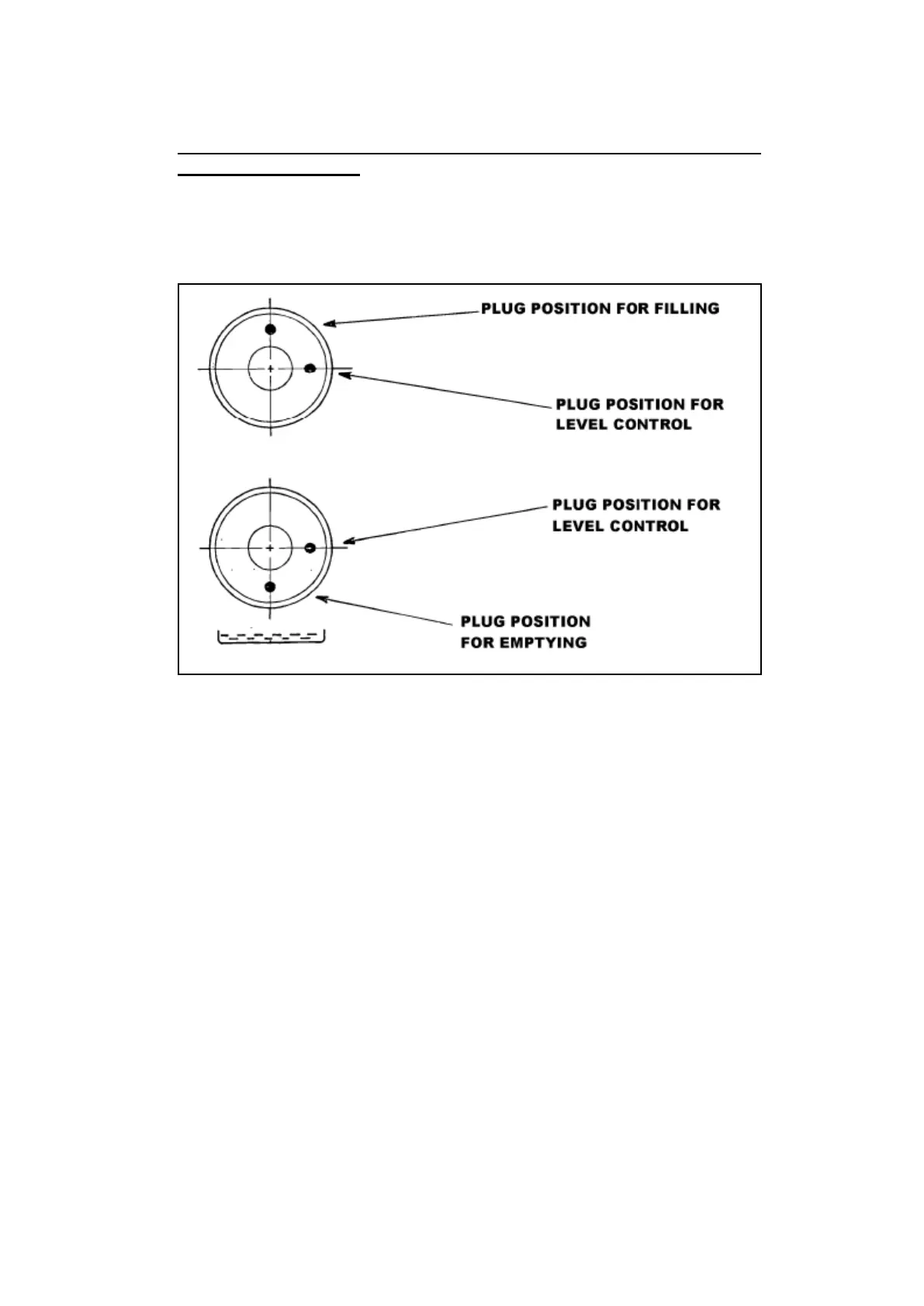

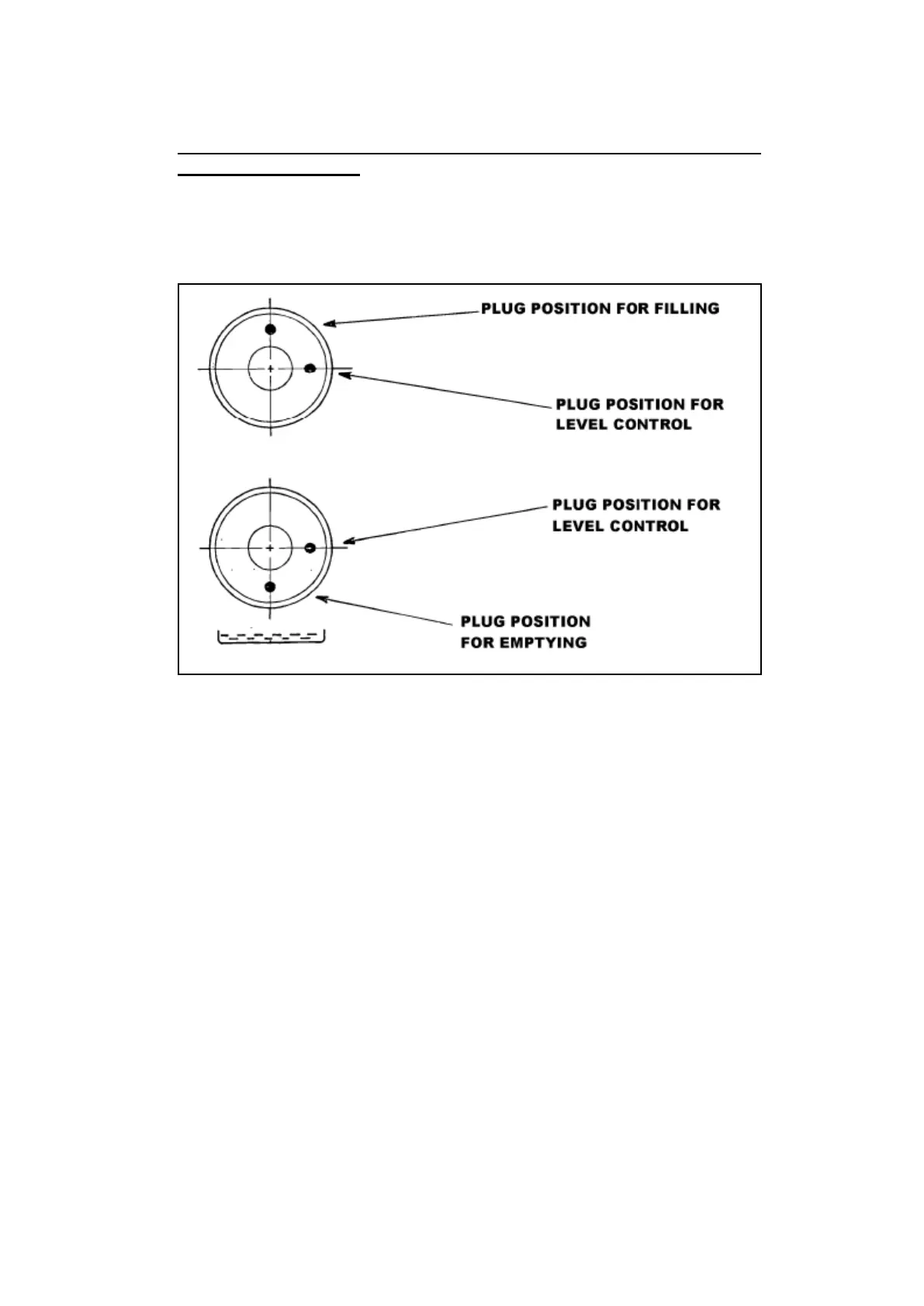

Periodically check for leaks and that, with the machine parked and the

gears positioned as illustrated below, the oil reaches the required

level: if necessary, top up.

FIGURE 5.5 – WHEEL REDUCTION GEARS PLUG POSITION

WARNING: When more than 10% of the total quantity needs to be

topped up, it may be an indication of a gear leak.

The first oil change must be done after the first 100 hours of

operation. Subsequent oil changes are done after 1,000 hours or at

least once a year.

- Capacity of each single reduction gear: 0.3 L

- For the type of lubricant, refer to the lubrication table.

The emptying of the gear is done immediately after operation when the

oil is still hot to avoid deposits of impurities.

Pay careful attention when emptying, as the hot oil may cause serious

burns. Clean the plug with detergent, taking extreme care to keep it

clean during the refilling phase. Cleanliness is essential for the proper

functioning of the machine and the hydrostatic system, in particular.

The brake does not require any specific maintenance. The controls are

limited to periodic checks of the gear oil level and external leaks.

In case of a decrease or increase in the oil level inside the gear and

with no external leaks, the internal gear gaskets must be overhauled

by an authorised service centre.

Loading...

Loading...