Function

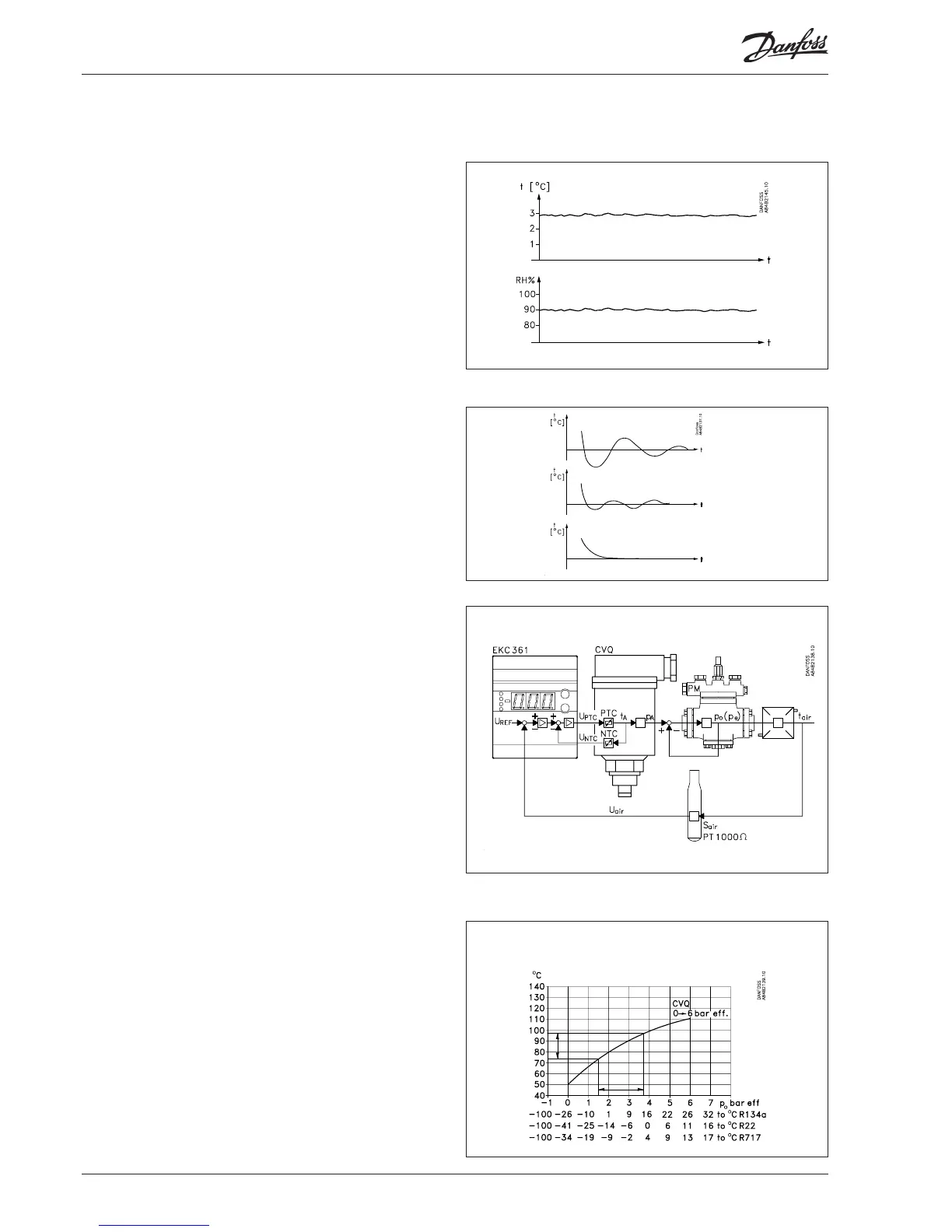

Very accurate temperature control

With this system where controller, pilot valve and main valve have

been adapted for optimum use in the refrigerating plant, the re-

frigerated products may be stored with temperature uctuations

of less than ±0.25°C.

High air humidity

As the evaporating temperature is constantly adapted to the

refrigeration needs and will always be as high as possible with a

very small temperature uctuation, the relative air humidity in the

room will be kept at a maximum.

Drying-out of the products will in this way be reduced to a mini-

mum.

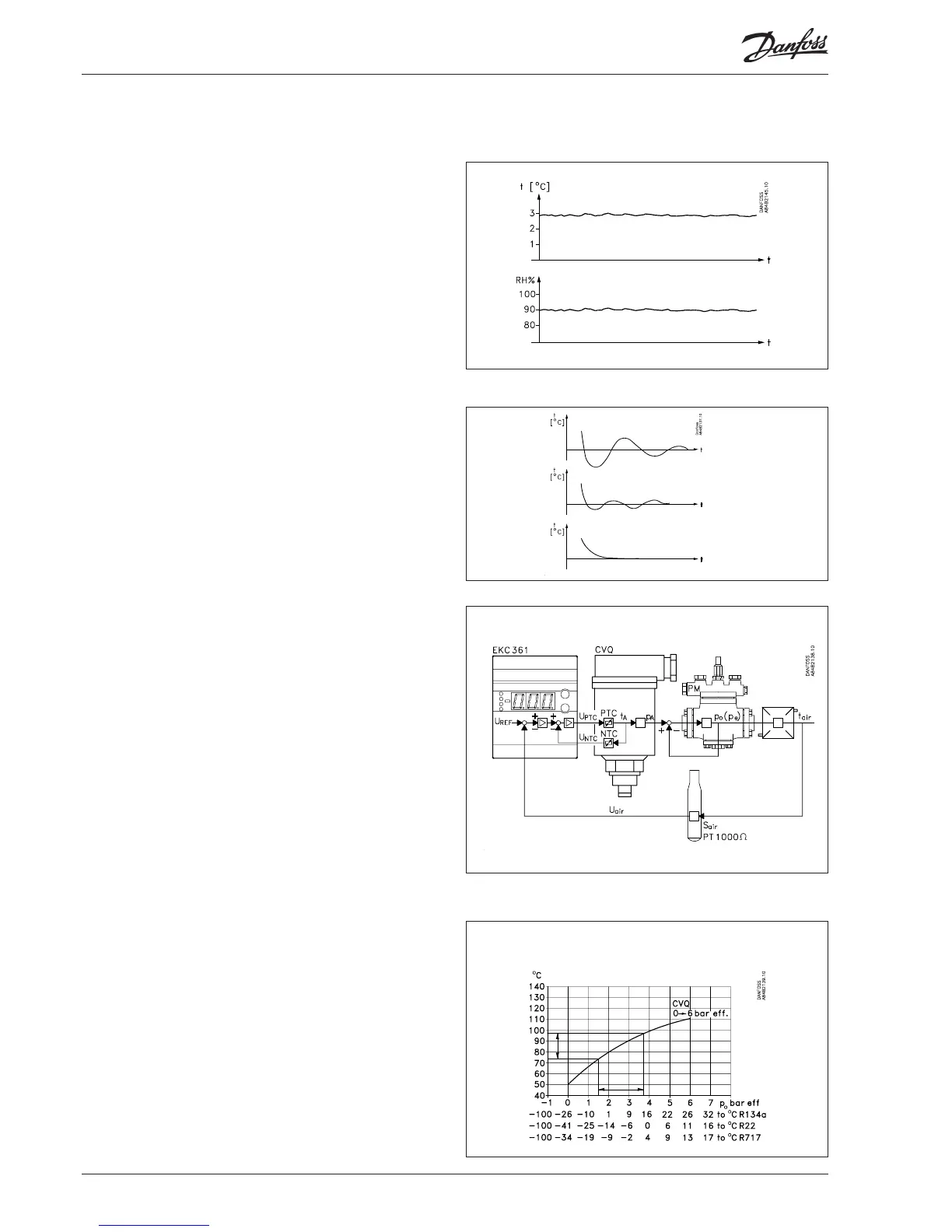

Temperature is quickly attained

With the built-in PID control and the possibility of choosing be-

tween three transient phenomena, the controller can be adapted

to a kind of temperature performance that is optimum for this

particular refrigerating plant. See parameter (n07).

• Fastest possible cooling

• Cooling with less underswing

• Cooling where underswing is unwanted.

Regulation ICS/PM with CVQ

The controller receives signals from room sensor S

air

. This room

sensor must be placed at the air outlet from the evaporator to

obtain the best possible regulation. The controller sees to it that

the required room temperature is maintained.

Built-in between the controller and the actuator is a so-called

inner control loop which constantly checks the temperature (pres-

sure) in the actuator’s pressure vessel. In this way a very stable

control system is obtained.

If there is a deviation between the required and the registered

temperature the controller will immediately send more or fewer

pulses to the actuator to counteract the error. A change of the

number of pulses will act on the temperature and hence the

pressure in the pressure vessel. As the charging pressure and the

evaporating pressure p

0

follow each other, a changed charging

pressure will produce the effect that the valve’s opening degree is

also changed. The ICS/PM with CVQ system maintains the pressure

in the evaporator whatever pressure changes there may be on the

suction side (on the ICS/PM valve’s outlet).

Evaporating pressure limitation (p

0

limitation)

The inner control loop mentioned above also causes the evapora-

ting pressure to stay within a xed limit. In this way the system is

safeguarded against a too low supply air temperature.

It oers the following advantages:

- High-temperature systems can be connected to low-tempera ture

compressor units

- Protection against icing on evaporator

- Frost protection of liquid coolers

Regulation with ICM

When using ICM as selected valve the system will still control ICM

in order to maintain S

air

according to entered setpoint.

This system does not inlude any inner control loop.

It is a direct operating and pressure independent valve for control-

ling media temperatur. (S

air

).

The allowed temperature in the actuator determines the evapora ting pressure

Actuator temperature

Loading...

Loading...