3. Wash the foam element in liquid detergent and water. Squeeze dry the foam element in a clean cloth.

4. Saturate the foam element with clean engine oil. To remove the excess engine oil, squeeze the foam

element in a clean cloth.

5. Install the foam element into the air cleaner case

6. Close the air cleaner cover and tighten the two wing bolts securely.

9.8 SPARK PLUG

Recommended Spark Plug: F7RTC(TORCH).

The recommended spark plug is the correct heat range for normal engine operating temperatures.

WARNING: Incorrect spark plugs can cause engine damage.

For good performance, the spark plug must be properly gapped and free of deposits.

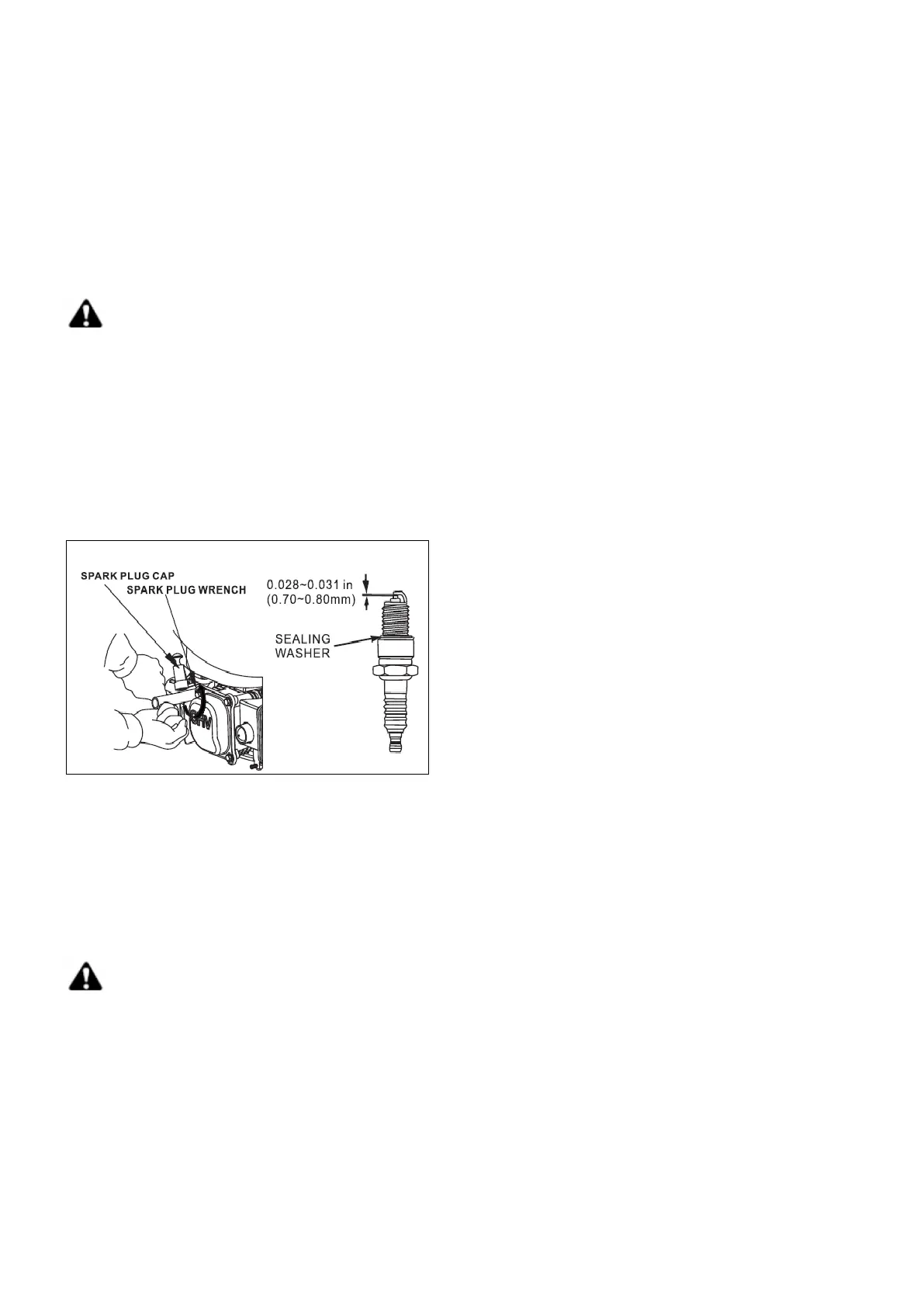

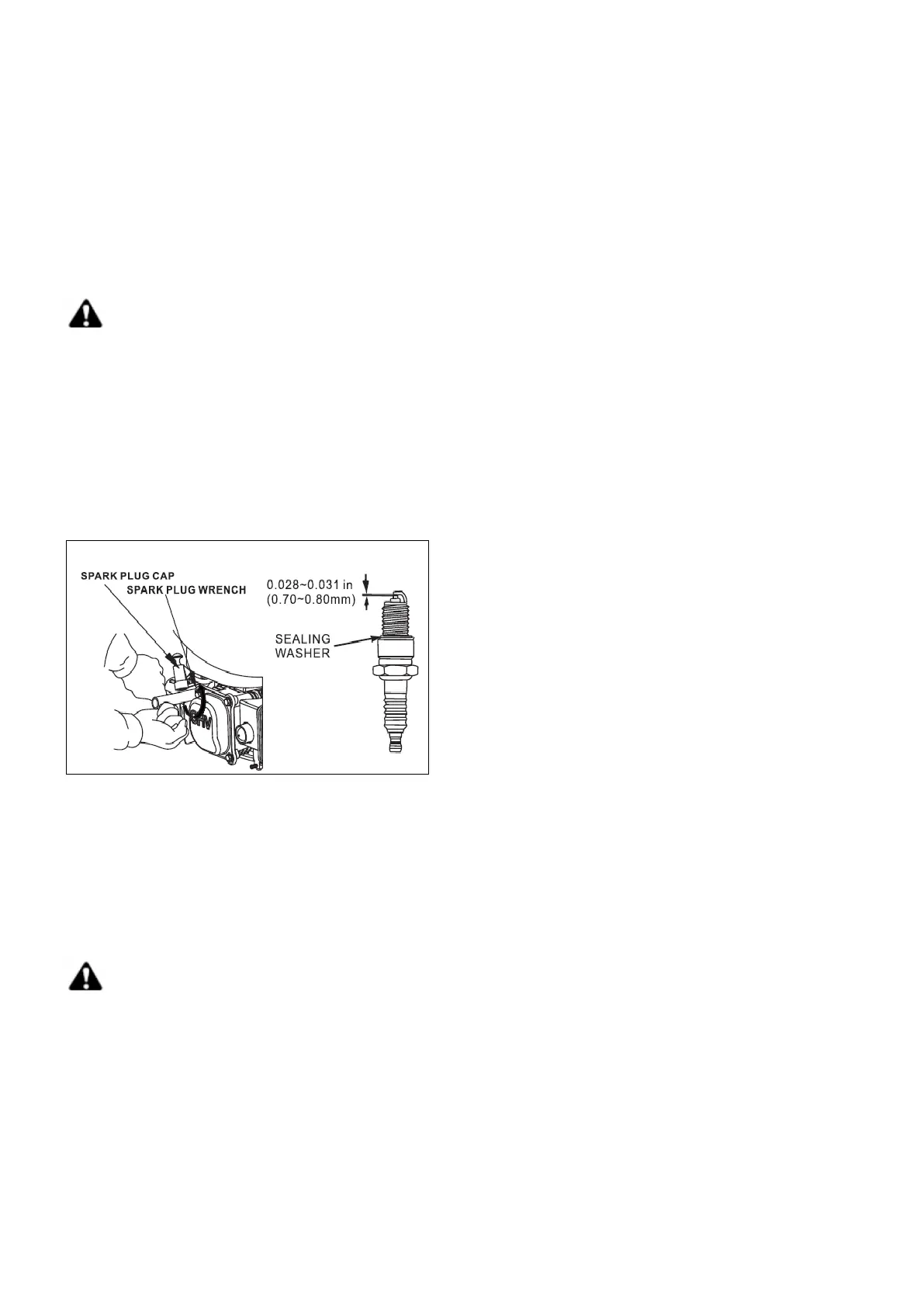

1. Disconnect the cap from the spark plug, and remove any dirt from the spark plug area.

2. Use the proper size spark plug wrench to remove the spark plug.

3. Inspect the spark plug. Replace it if damaged, badly fouled, if the sealing washer is in poor condition, or if the

electrode is worn.

4. Measure the electrode gap with a suitable gauge. The correct gap is 0.028 - 0.031 in (0.70-0.80 mm). If

adjustment is needed, correct the gap by carefully bending the side electrode. (See Fig. 11)

Fig. 11

5. Install the spark plug carefully, by hand, to avoid cross-threading.

6. After the spark plug is seated, tighten with the proper size spark plug wrench to compress the washer.

7. When installing a new spark plug, tighten 1/2 turn after the spark plug seats to compress the washer.

8. When reinstalling the original spark plug, tighten 1/8-1/4 turn after the spark plug seats to compress the

washer.

WARNING: A loose spark plug can become very hot and can damage the engine. Over tightening the

spark plug can damage the threads in the cylinder head.

9. Attach the spark plug cap to the spark plug.

9.9 FLYWHEEL BRAKE INSPECTION

1. Check to see if the inspection screw is contacting the brake bracket.

2. If the inspection screw is contacting the brake bracket, take the engine to an authorized engine servicing

dealer for flywheel brake pad inspection.

3. Release the tarter control handle (located on equipment) and verify that there is a strong resistance when

Loading...

Loading...