STEP ONE: ISOLATING THE PR

OBLEM

NOTE: Before addressing any specific

problem the unit may have, it is advisable to help

isolate the nature of the problem by running a

general check of the 1) Gas Supply and 2)

Electrical Supply. The following procedure will

narrow the possibilities and help direct you to

the source of the problem. A detailed

Troubleshooting section with specific symptoms

and likely corrective courses of action follows

each sub-assembly Partlist section.

CHECK GAS SUPPLY

First, check to see if the gas has been tur ned on.

Next, gain access to the regulator by remov-

ing the grates over the cooktop burners on the far

left hand side of the cooktop. Beneath the grates,

to wards the rear of the burner box, the regulator is

loca ted between the manifold and rear incoming gas

line. Check the top of the regulator to see that it is set

up for the type of gas supplied to the unit. The cap

on top of the regulator indicates whether the unit is

set up for NATURAL or L.P. gas.

When the gas supply is on, check the gas

pr essur e with a manometer. The front main open top

burner orifice is the most convenient place to check

gas pressure. T o access the main burner orifice,

remove the four (4) screws that hold the bur ner

hanger do wn and A) move aside the bur ner assembly

or B) disconnect the igniter wires and remove the

entire burner / hanger assemb ly. Hook up a flexible

line to the main burner orifice, turn that burner on...

the pressur e should read 5.0" W.C. for Natural Gas,

and 10.0" W.C. for L.P. Gas. Turn on other bur ners

and check f or an excessive drop in pressur e. A large

dr op in pr essur e indicates a gas supply pr ob lem relat-

ed to installation, not covered by service warranty.

CHECK ELECTRICAL SUPPLY

First, check to see if the electricity has been turned on.

Next, check power to the cord in the back of

the rang e and at the wall r eceptacle. If power is OK

ther e, the next area to check will be at the service dis-

connect located behind the valve panel. The Valve

Panel can be removed by removing the five (5) scr ews

that hold it in place. Two (2) scr ews ar e located at

each end of the panel, while one (1) screw (painted

Red) behind a Burner Control knob must also be

removed before the valve panel can be removed.

Once the Valve Panel has been removed, unplug and

check for power to the female side of the plug.

Between 110 & 120 volts should be present, if not,

ther e is a prob lem with the cord.

Check for power at the Terminal Blocks,

(Black= Live, White = Neutral)

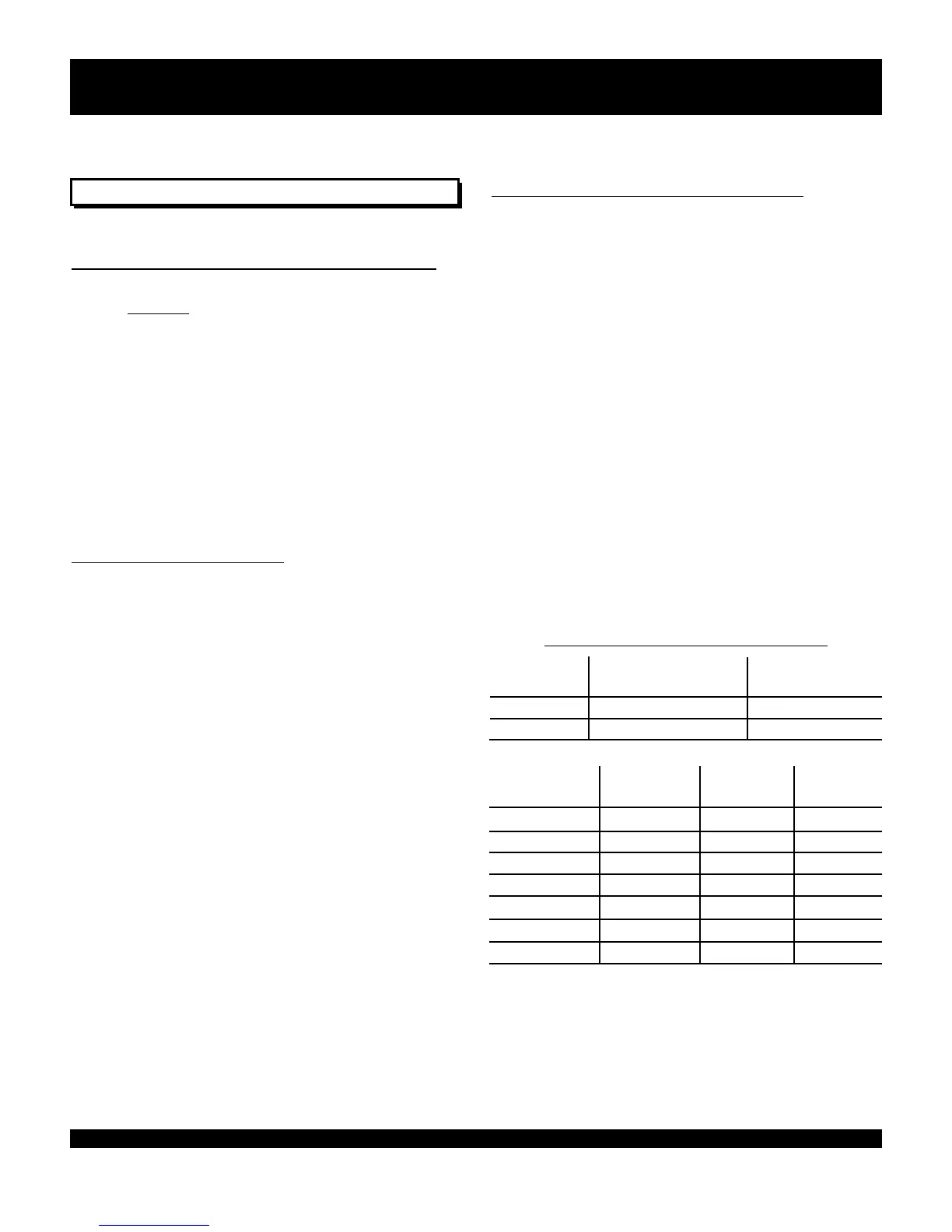

ORIFICE or PIN SIZE R

eferences:

Gas Type Incoming Pressure Pressur e Regulator

to Regulator Supplies

NATURAL 7.0" to 9.0" W.C. 5.0" W.C.

L.P. 11" to 14.0" W.C. 10.0" W.C.

Orifice Size Pin Size Orifice

Size Nat. (DMS) LP (DMS) LP (DMS)

Open Top 51 57 50

Center Simmer 78 87 80

Grill 48 55 55

Griddle 48 55 55

Infra Red Broiler 47 55 55

Small Oven 48 55 55

Large Oven 38 52 52

*NOTE: Ensure the Air Shutter is installed when converting

an I/R Broiler to L.P,. See Gas Hookup Section, Range

Installation Manual.

GENERAL INSTRUCTIONS:

3

INTRODUCTION

Loading...

Loading...