MAN-PTS-GB, Revision 9, BSC, 15-FEB-2017 15/46

3 CONSTRUCTION AND OPERATION

The chamber is the main part of the PTS technology. The PTS filter is located in the upper part of

the chamber, between the body and the cover. The system consists of 4 valves which are

connected to a control system. The valve "product inlet" V1 and the valve "product outlet" V2

are directly mounted on the chamber. The valve connected to the vacuum and the valve

connected to a pressure source are either connected to the PTS cover by a flexible hose or

directly mounted on the PTS cover.

The valves open and close automatically according to a logical sequence in order to alternate

the filling and emptying cycles of the PTS chamber. The system, from its principle, can transfer

products dust-free without changing their homogeneity. It can, furthermore, fill closed vessels

without the introduction of oxygen.

The suction and emptying times and the frequency of the cycles can be easily adjusted

according to the process conditions. The figures below describe the different PTS steps in detail.

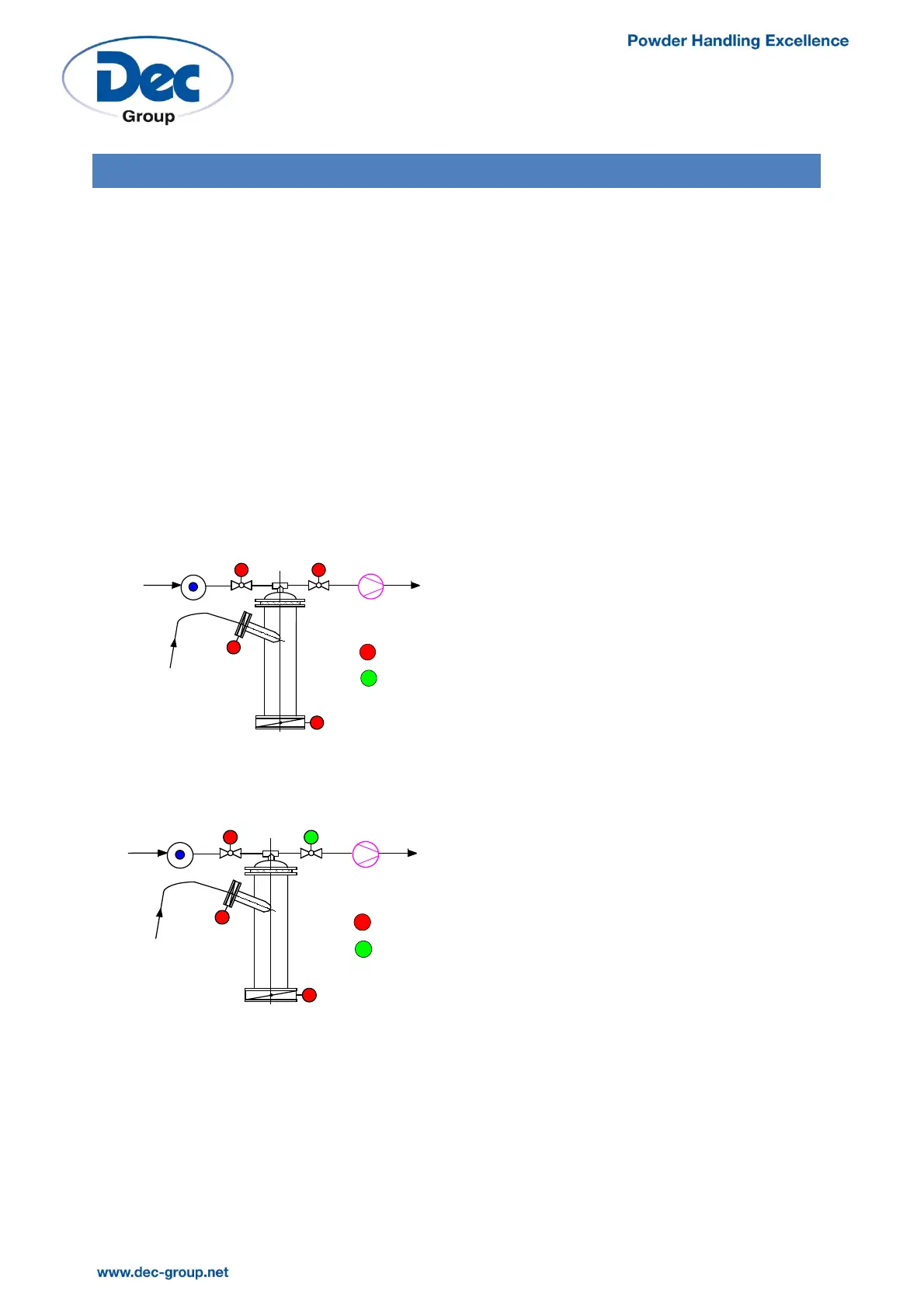

In the shutdown position, all the valves

are closed.

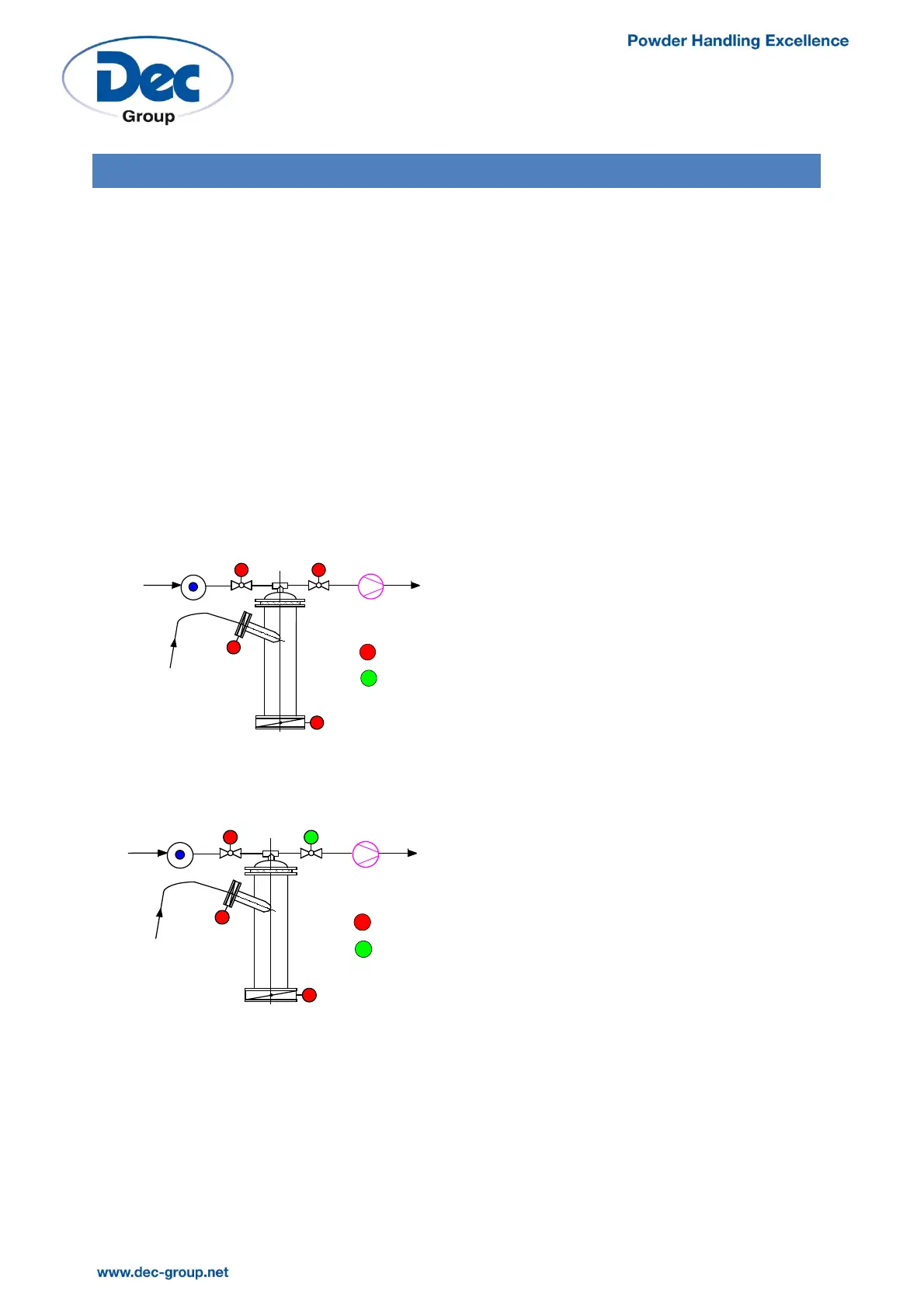

At the beginning of the suction phase,

the vacuum valve V3 opens. Vacuum is

created in the PTS chamber by the

vacuum pump connected to valve V3.

VACUUM

PUMP

PRESSURE

POWDER

V1

Valve closed

Valve open

V2

V3

V4

VACUUM

PUMP

PRESSURE

POWDER

V1

Valve closed

Valve open

V2

V3

V4

Loading...

Loading...