14

Pressured up pump operation

Key 1 + 7

To check that the pump is pressured up. (this is done to check for eventual leaks inside the machine)

Steam boiler electric current

Key 4 + 6

Check the electric current using an ammeter.

During the temperature rise approx. :

4.8 A (230 V);

9 A (120V);

11 A (100V)

Coffee boiler electric current

Key 2 + 6

Check the electric current using an ammeter.

Boiler temperature

Key 4 + 6 + 7

This function is used to check the current temperature of the coffee boiler

Contrast LCD Key 1 + 6 + 7

Back-light LCD Key 2 + 6 + 7

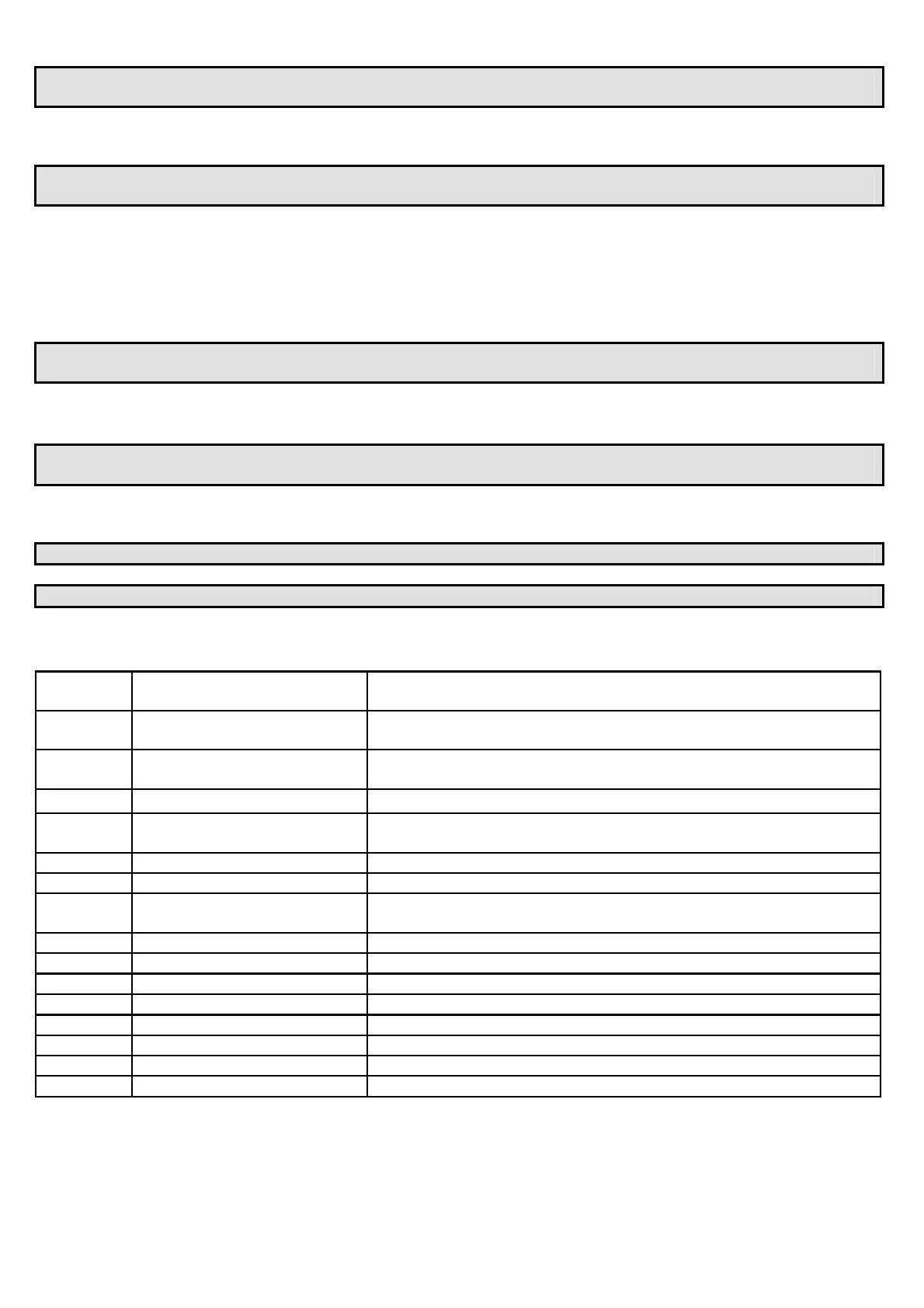

3.4 Checking micro-switches in Test Mode

Display

N°

Micro-switch Function

1

Geared motor in distribution

phase switch

It sets the stopping point of the group’s rise

2

Geared motor on standby

switch

It sets the stopping point of the group’s descent

3 Panel switch

5

Coffee ground tray and drip

tray switch

Detects the presence of the coffee grounds tray and the drip tray

6 Coffee group switch Detects the presence of the coffee group

7 Door switch Detects the correct shutting of the door

8

Turbine sensor Counts the turbine impulsions in order to define the quantity of water to

be used when making the coffee

9 Coffee grinder sensor Defines the number of revolutions depending on the dose of coffee

0 Water sensor Detects when there is insufficient water in the tank

A Water tank safety sensor Detects when the water tank is full

M No Coffee Detects when there is no more coffee in the coffee holder

R RTC control Detects correct function of the clock (it should blink)

K Facade detector Detects the presence of the facade

0-8 Coffe grinder setting Detects the coffee grinder settings in factory control phase

* Coffee grinder impulses Indicates whether the value on the previous line (0-8) was saved

Loading...

Loading...