4

INSTALLATION & OPERATION MANUAL

SONAC/120 LIQUID LEVEL SWITCH

DECEMBER 2008 REV 1.0

1.0 INTRODUCTION

1.1 Description

This device is a single point, electronic switch for ON-

OFF level control of liquids, at temperatures from -65ºF

(-54ºC) to 400ºF (204ºC) and pressures to 4000 psi.

Typical applications include, crude and rened petroleum,

hot asphalt, solvents, chemicals, liqueed air fractions, LPG,

LNG, and most other liquids

1.2 Principle of Operation

The SONAC/120 Switch is comprised of a sensor,

interconnecting cable and electronic control unit.

The sensor is a magnetostrictive device consisting of a

diaphragm, nickel drive tube, bias magnet, drive coil and

pickup coil. The sensor diaphragm is electronically driven

to oscillate at its resonant frequency with a high-velocity, low

amplitude motion. When the product level covers the sensor,

the diaphragm is dampened. This produces a change in the

output signal level from the sensor’s pickup coil. The control

amplier, which is in a regenerative feedback loop circuit

with the sensor, processes the signal change, and actuates

the output relay for the desired end function.

SELF-TESTING FEATURE: A logic network is included

in the feedback loop to “prove” the mechanical and electrical

integrity of the sensing circuit. If an open or short circuit

occurs in the sensor connecting cable, or control amplier,

the relay immediately transfers to the alarm condition.

1.3 Specications

Supply Voltage Normal Absolute Limits

115 VAC 95-135 VAC

230 VAC 190-270 VAC

or 12-24 VAC

12-24 VDC

Frequency, AC Power 50-60 Hz 45 Hz Minimum

Time Delay Standard, 50 ms to

Adjustable 15 seconds

Failsafe Switch selectable, High

or Low Level

Environmental Rating NEMA 4X, IP55

Control Unit

Temperature Amplier -40 to 75ºC

Sensor Temperature, Temperature and pressure

Pressure Rating limits vary with sensor

model. Consult SONAC/120

data sheet for specication

information.

Sensor Mounting/ 1” NPTM

Process Connection

Distance-Sensor to Control 150 ft (45.7M with PVC

Unit, Maximum

Insulated Cable (BLUE)

100ft (30.5M) with TFE

Insulated (WHITE)

Indicators Two, light emitting diodes (LED).

RED - Illuminated when product is

present at sensor

YELLOW - Illuminated when relay is

energized

Output Relay, DPDT 2 Form C Contracts

5 A at 120 VAC Non-Inductive

3 A at 240 VAC Non-Inductive

3 A at 24 VDC Non-Inductive

Shipping Weight Control: 5 Pounds (2.5 Kilograms)

Sensor: 1.6 Pounds (.68) Kilograms

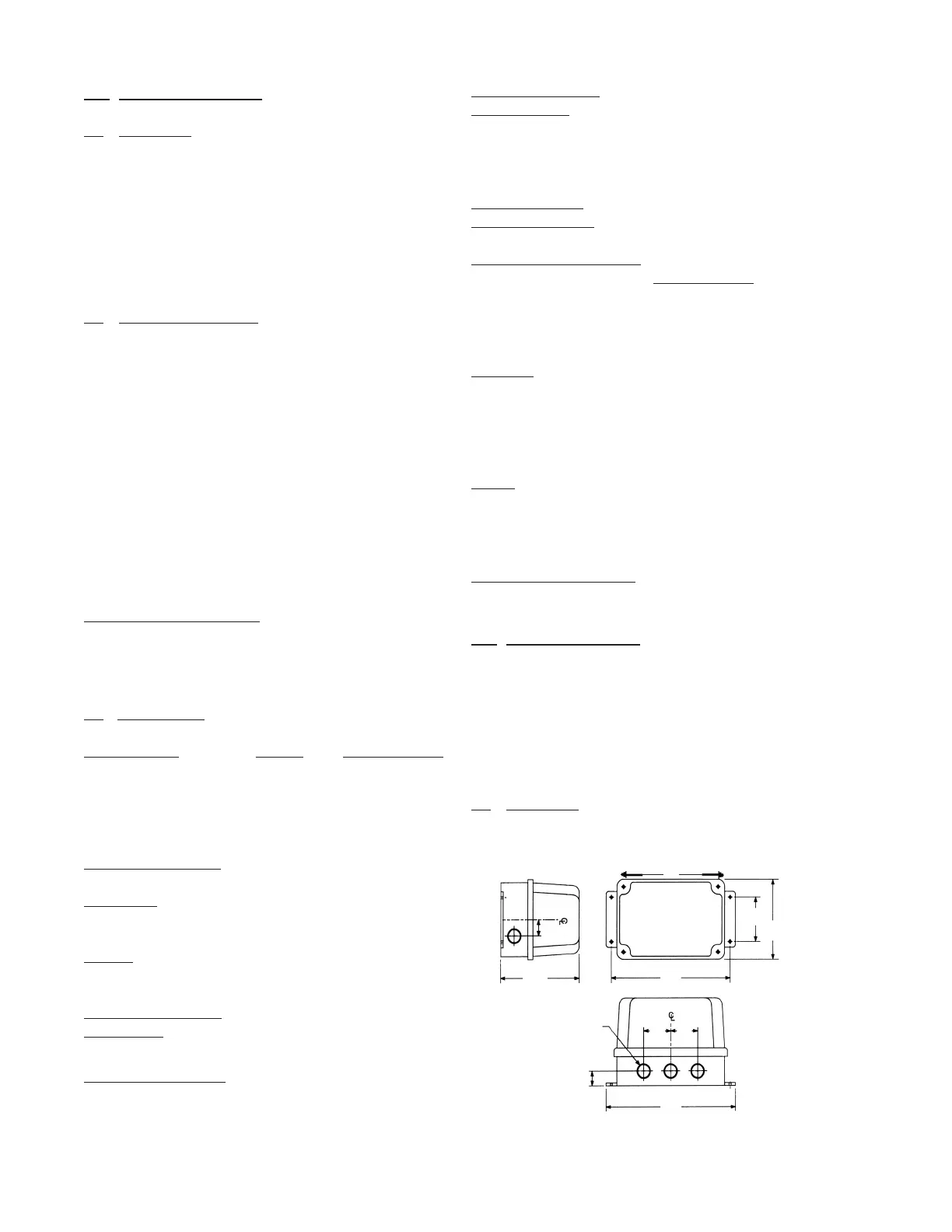

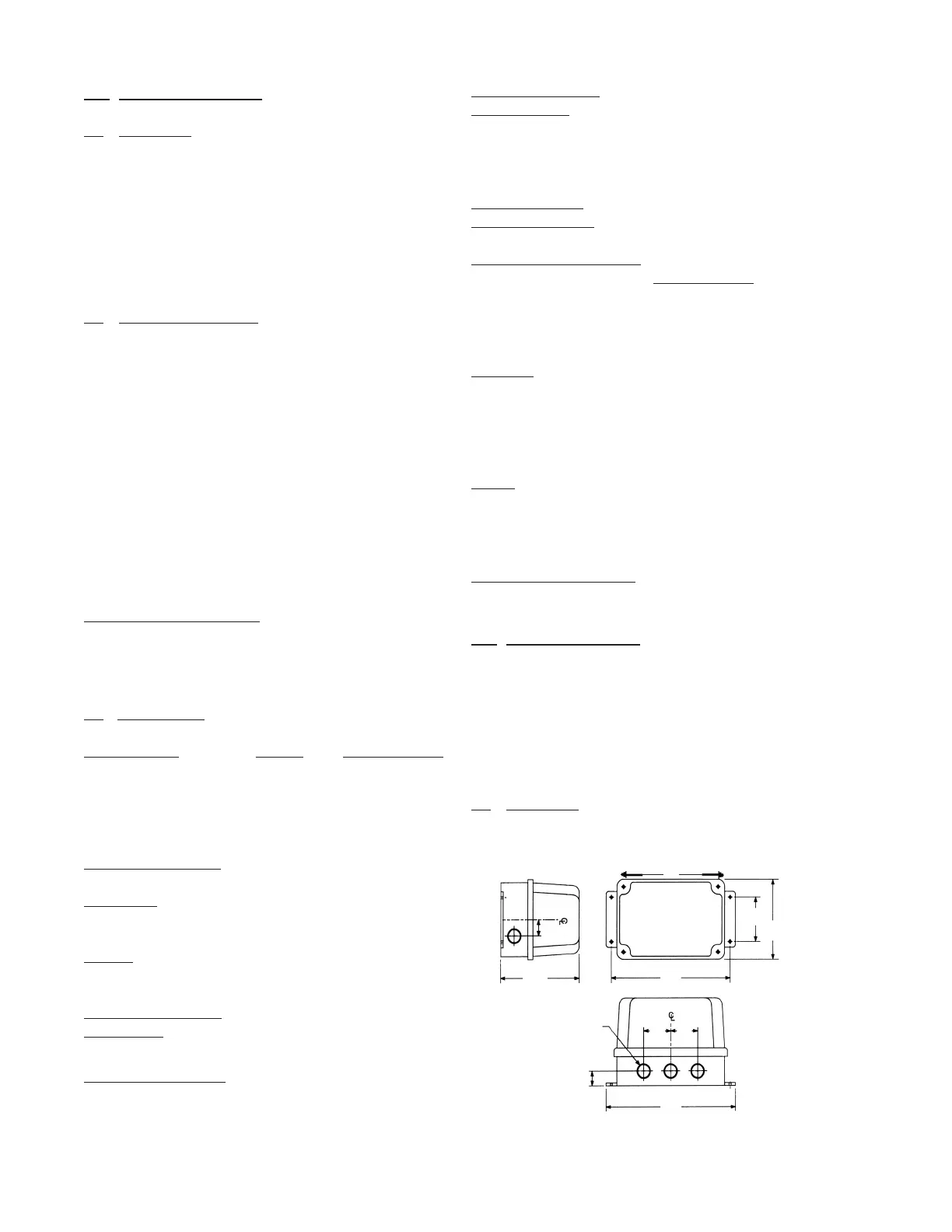

2.2 Mechanical

AMPLIFIER HOUSING

.875

(22.2)

2.00

(51)

6.000

(152.4)

1.062

(27)

8.625

(219)

2.00

(51)

3.00

(76.2)

9.375

(238)

1/2” Condult knockout

8.187

(208)

5.179

(131.5)

INSTALLATION DRAWING

NOTE: DIMENSIONS IN PARENTHESES DENOTE MILLIMETERS

2.0 INSTALLATION

2.1 Unpacking

Remove the system from the shipping carton and check the

nameplate model number against the packing list before

destroying any packing material. Remove plastic protective

closures from sensor

Loading...

Loading...