Delem

V1101, 4.19

4.7 The spindle correction table

With this feature an axis position can be corrected for deviations in the spindle. The spindle

deviations can be programmed in a table. The correction at every other position of the spindle is

computed by means of linear interpolation.

A method to determine the contents of this table can be the following:

• First adjust the reference position of the axis.

• Program a value for the axis position in Manual mode and press start. Measure the actual

backgauge position.

• Repeat this procedure several times.

• Compute the deviation of each measured point according to the following definition:

)(Delta) = measured value - programmed value

Note

The number of points which must be measured depends on the specification of the spindle.

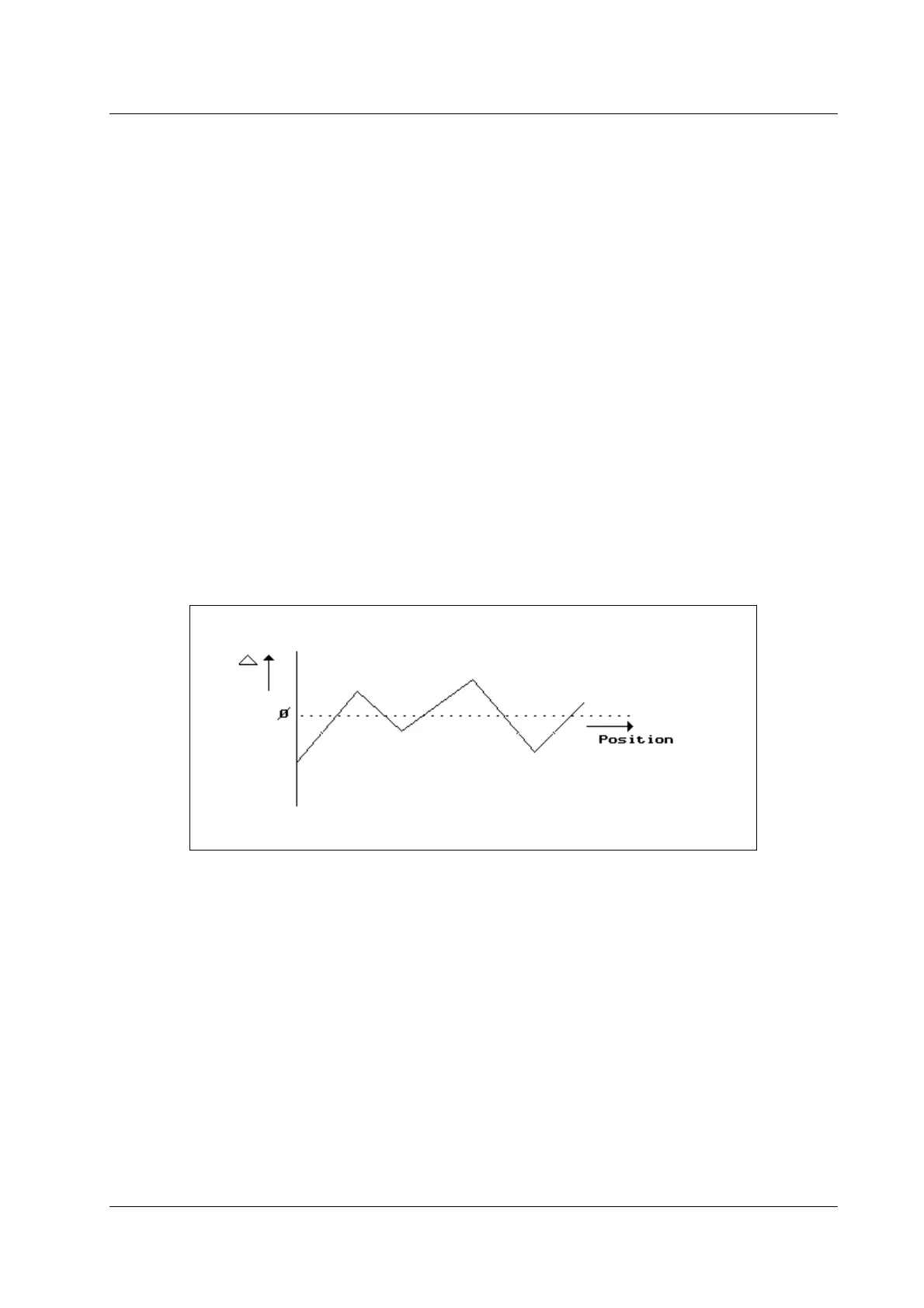

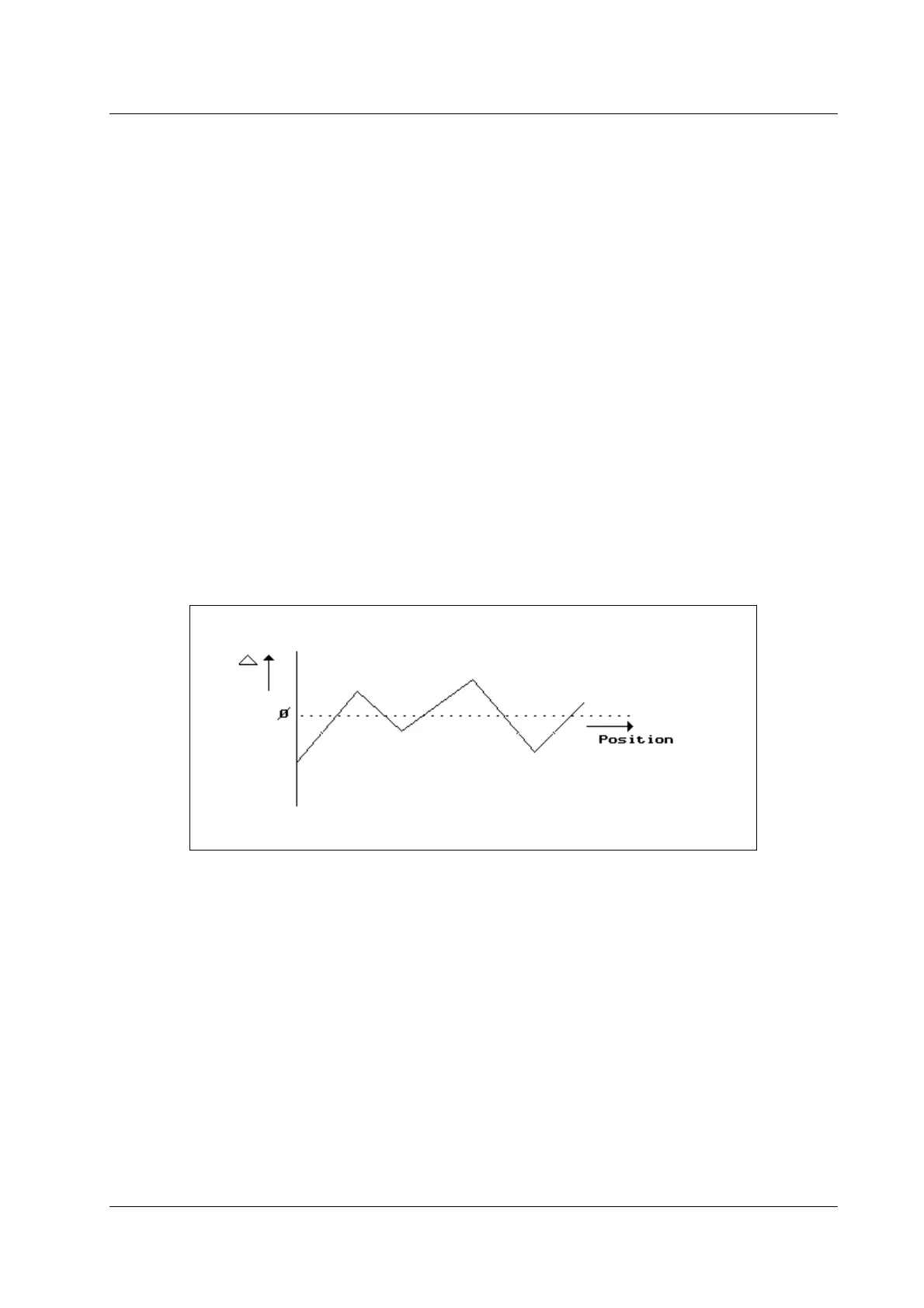

• Now make a graph of these results.

Figure 4.7.a

Select up to the maximal number of points from this graph which will give the best

approximation of the original curve. These points must be programmed in the table.

The resolution of the axis values in the correction table is 1mm. The resolution of the deviation

(delta) is 10 times the axis resolution. E.g. axis resolution is 0.1 mm, then the resolution of the

deviation is 0.01mm. The points must be programmed in an increasing order of the axis

positions. The length of the intervals between the points may vary. An entry with the axis

position not programmed (____) or programmed with a lower value as its predecessor will be

considered as the end of the table.

Loading...

Loading...