Delem

V1101, 9.30

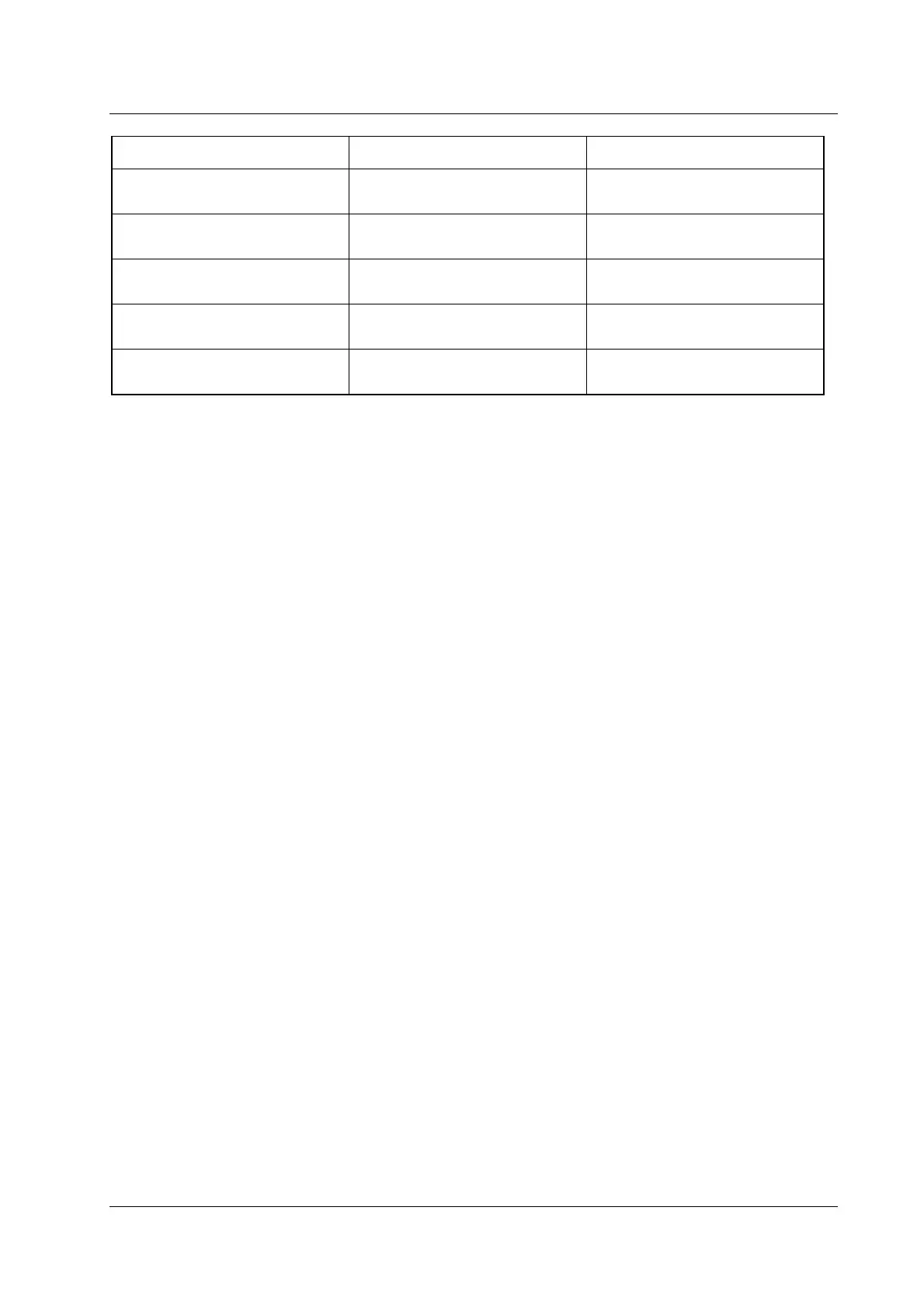

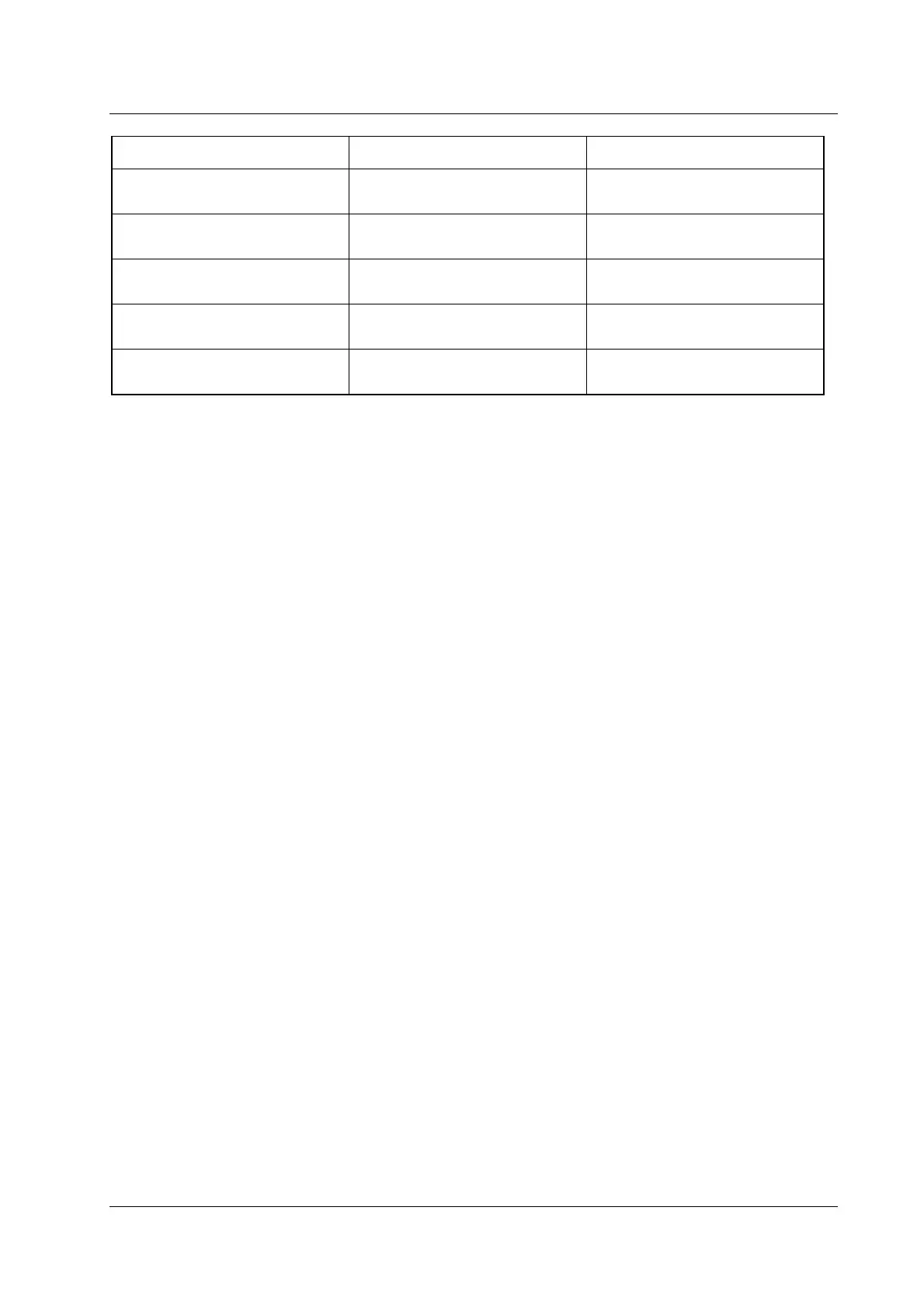

Potentiometer nr. Function Start position

RP1 offset feedback minimal = completely turned

to the right

RP2 gain feedback maximal = completely turned

to the left

RP4 gain braking on Y-brake minimal = completely turned

to the left

RP5 slip factor minimal = completely turned

to the left

RP6 gain differential minimal = completely turned

to the left

C The potentiometers RP3, RP7, RP8, RP9 and RP10 are factory set to optimal values.

Adjustment procedure part support

C Go to the diagnostic mode

C Select DM01 module that controls the part support.

C Move cursor to the speed output parameter ‘output0' with cursor key.

C Select 0 (= 0%).

C Start the machine and the hydraulic pump of the part support construction.

C Follow the next adjustment procedures:

** Adjustment of the feedback offset (see O1 in the blockdiagram of principle PID-

controller)

C Turn RP1 until the part support is in the horizontal position.

In case the part support can not be adjusted in an optimal way turn potentiometer RP6 a

couple of turns to the right.

** Adjustment of the feedback gain (see A1 in the blockdiagram of principle PID-

controller)

C Select 50% of ‘output0'. This corresponds with the value 127.

C Turn potentiometer RP2 until the part support brackets are exactly halfway the maximum

required angle.

** Adjustment of the differential gain (see A3 in the blockdiagram of principle PID-

controller)

C Leave the diagnostic program.

C Program the part support machine parameters before continuing this procedure. See

section 9.3.

C Select the manual mode.

C Program the manual mode parameters and program the pressing speed not too high, e.g. 2

mm/s.

C Make some pressing movements and turn potentiometer RP6 during the pressing phase

so, that the part support is not oscillating and following the pressing movement fluently.

** Adjustment of the slipfactor (differentiating gain D in the blockdiagram of principle PID-

controller)

Loading...

Loading...