Automatic Transmission

G:07:07

JW^i

!'••-'•

f

'^\

7*$5

wm,

^

r^f\

rwrst

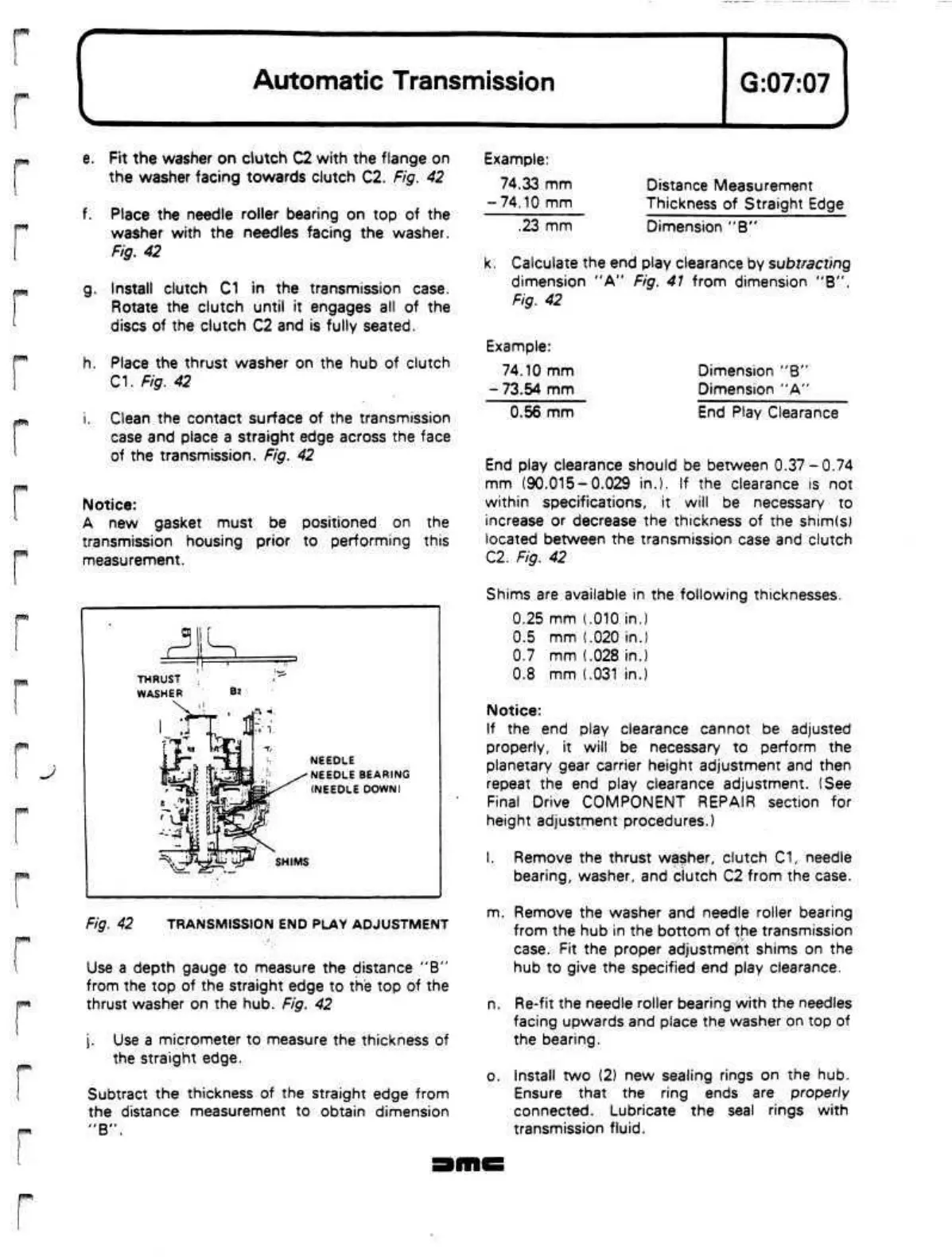

e. Fit the washer on clutch C2 with the flange on

the washer facing towards clutch C2. Fig. 42

f. Place the needle roller bearing on top of the

washer with the needles facing the washer.

Fig. 42

g.

Install clutch C1 in the transmission case.

Rotate the clutch until it engages all of the

discs of the clutch C2 and is fully seated.

h. Place the thrust washer on the hub of clutch

C1.

Fig. 42

i. Clean the contact surface of the transmission

case and place a straight edge across the face

of the transmission. Fig. 42

Notice:

A new gasket must be positioned on the

transmission housing prior to performing

this

measurement.

NEEDLE

NEEDLE BEARING

INEEDLE DOWN)

SHIMS

Fig. 42 TRANSMISSION END PLAY ADJUSTMENT

Use a depth gauge to measure the distance "B"

from the top of the straight edge to the top of the

thrust washer on the hub. Fig. 42

j.

Use a micrometer to measure the thickness of

the straight edge.

Subtract the thickness of the straight edge from

the distance measurement to obtain dimension

"B".

Example:

74.33 mm

-74.10 mm

.23 mm

Distance Measurement

Thickness of Straight Edge

Dimension "B"

Calculate the end play clearance by subtracting

dimension "A" Fig. 41 from dimension "B".

Fig. 42

Example:

74.10 mm

- 73.54 mm

0.56 mm

Dimension "B"

Dimension "A"

End Play Clearance

End play clearance should be between 0.37-0.74

mm (90.015-0.029 in.). If the clearance is not

within specifications, it will be necessary to

increase or decrease the thickness of the shim(s)

located between the transmission case and clutch

C2.

Fig. 42

Shims are available in the following thicknesses.

0.25 mm (.010 in.)

0.5 mm (.020 in.)

0.7 mm (.028 in.)

0.8 mm (.031 in.)

Notice:

If the end play clearance cannot be adjusted

properly, it will be necessary to perform the

planetary gear carrier height adjustment and then

repeat the end play clearance adjustment. (See

Final Drive COMPONENT REPAIR section for

height adjustment procedures.)

I.

Remove the thrust washer, clutch C1, needle

bearing,

washer, and clutch C2 from the case.

m. Remove the washer and needle roller bearing

from the hub in the bottom of the transmission

case.

Fit the proper adjustment shims on the

hub to give the specified end play clearance.

n. Re-fit the needle roller bearing with the needles

facing upwards and place the washer on top of

the bearing.

o. Install two (2) new sealing rings on the hub.

Ensure that the ring ends are properly

connected.

Lubricate the seal rings with

transmission

fluid.

Loading...

Loading...