r

r

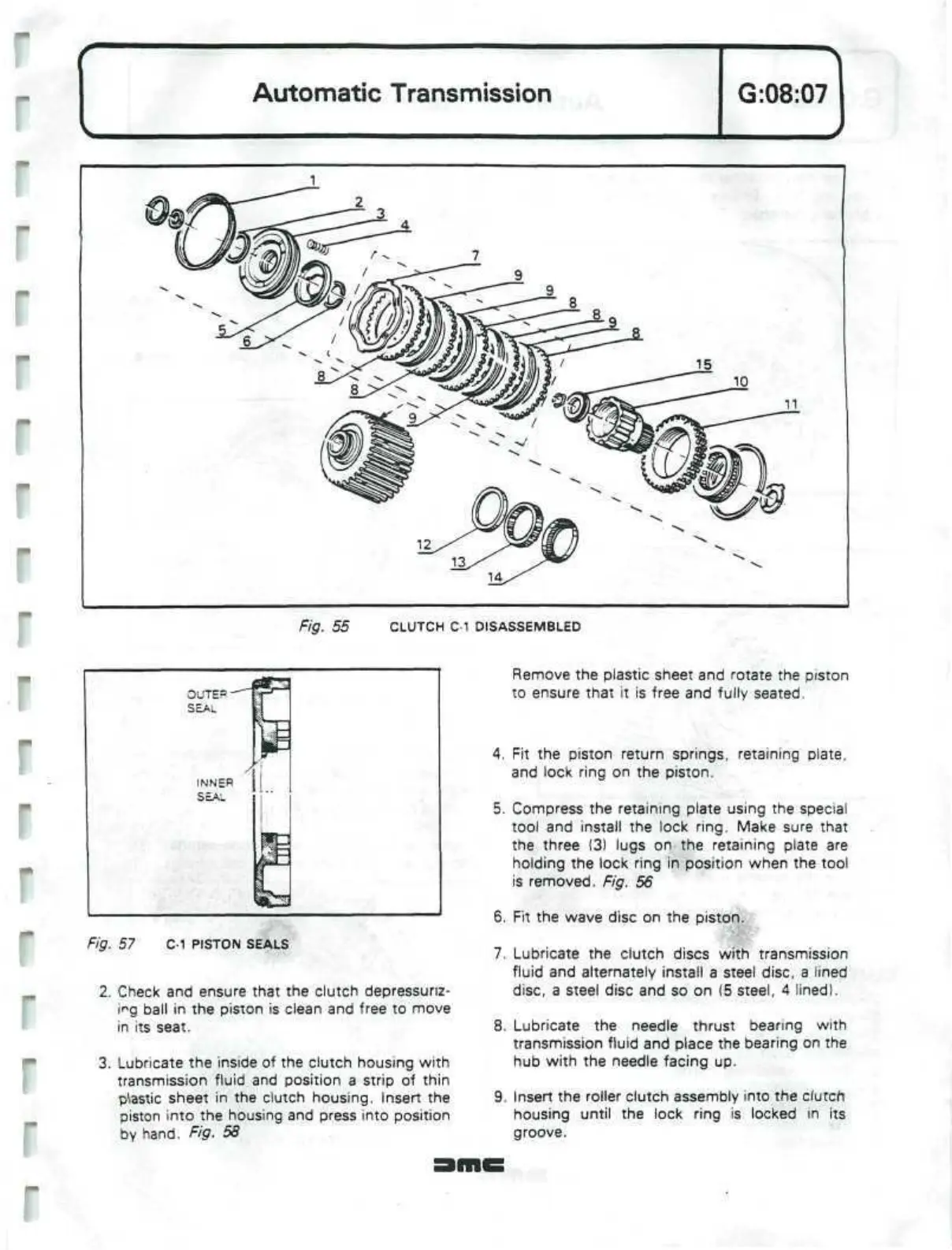

Fig. 55

CLUTCH

C-1

DISASSEMBLED

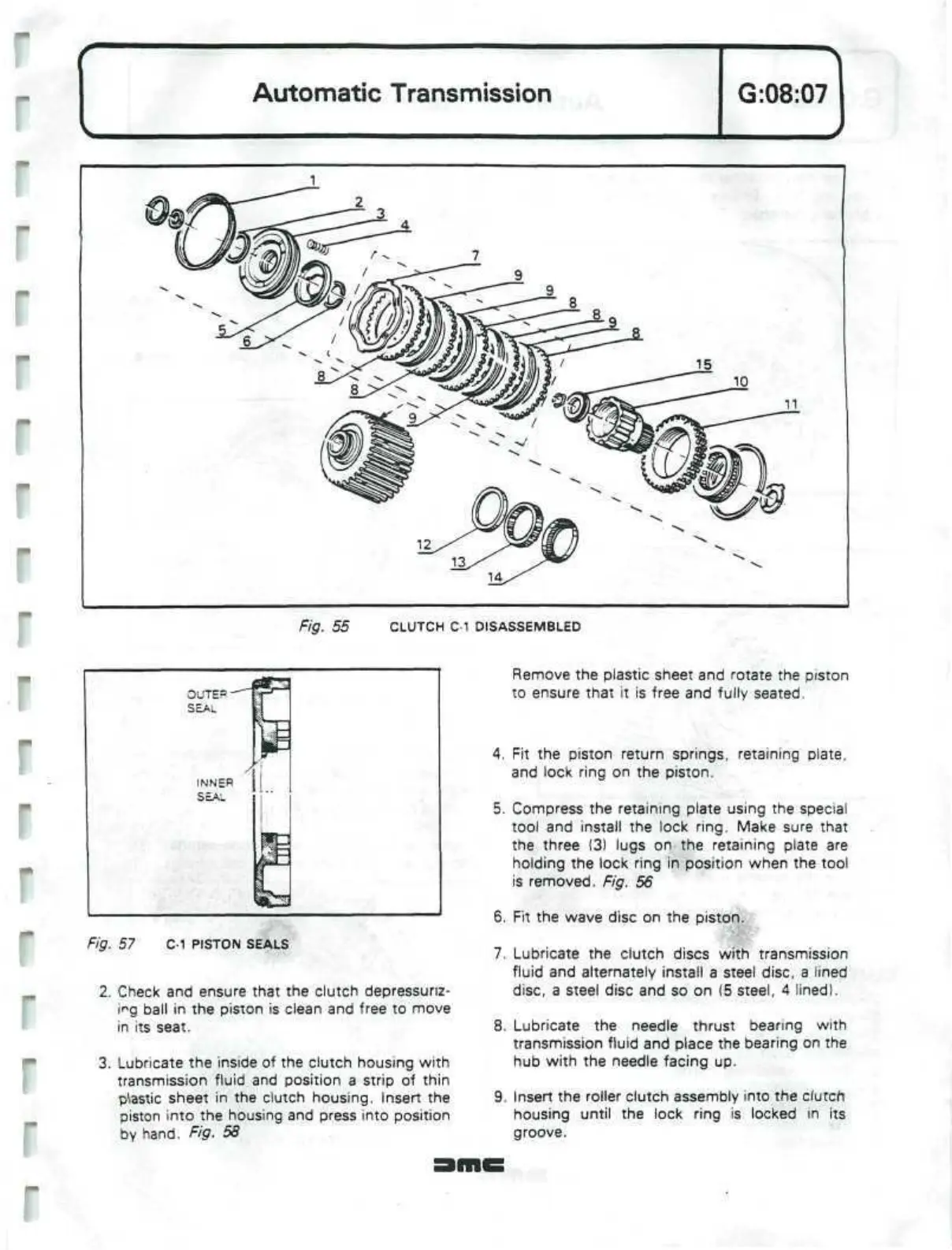

Fig. 57 C-1 PISTON SEALS

2.

Check and ensure that the clutch depressunz-

i^g

ball in the piston is clean and free to move

in its seat.

3. Lubricate the inside of the clutch housing with

transmission fluid and position a strip of thin

plastic

sheet in the clutch housing. Insert the

piston into the housing and press into position

by hand. Fig. 58

Remove the plastic sheet and rotate the piston

to ensure that it is free and fully seated.

4.

Fit the piston return springs, retaining plate,

and lock ring on the piston.

5. Compress the retaining plate using the special

tool and install the lock

ring.

Make sure that

the three (3) lugs on the retaining plate are

holding the lock ring in position when the tool

is removed. Fig. 56

6. Fit the wave disc on the piston.

7. Lubricate the clutch discs with transmission

fluid and alternately install a steel disc, a lined

disc, a steel disc and so on (5 steel, 4 lined).

8. Lubricate the needle thrust bearing with

transmission fluid and place the bearing on the

hub with the needle facing up.

9. Insert the roller clutch assembly into the clutch

housing until the lock ring is locked in its

groove.

Loading...

Loading...