Automatic Transmission

G:09:07

J-28866

Fig.

78

SIDE GEAR TOOL

J

Reassembly

Clean and inspect all parts for damage or scoring.

1.

Lubricate the thrust washer with gear oil and

place on the side gear with the lubricating

groove in the washer facing the gear.

2.

Install the side gear with the thrust washer

in

the carrier.

3. Lubricate the concave washers and place the

washers and spider gears in the carrier.

4.

Lubricate the spider gear shaft and insert in the

carrier aligning the pin hole in the shaft with

the hole in the carrier.

12.

Lubricate the seals and screw the adjusting

nuts into the half-cases until they contact the

bearing races.

Notice:

Carrier adjustments will be performed in the FINAL

DRIVE REASSEMBLY section.

FINAL DRIVE REASSEMBLY

Notice:

If the planetary gear carrier was disassembled for

repair, ensure that the bearing pre-load ana carrier

height adjustments are performed before re-

assembly of the final drive. See FINAL DRIVE

COMPONENT REPAIR section for adjustment

procedures.

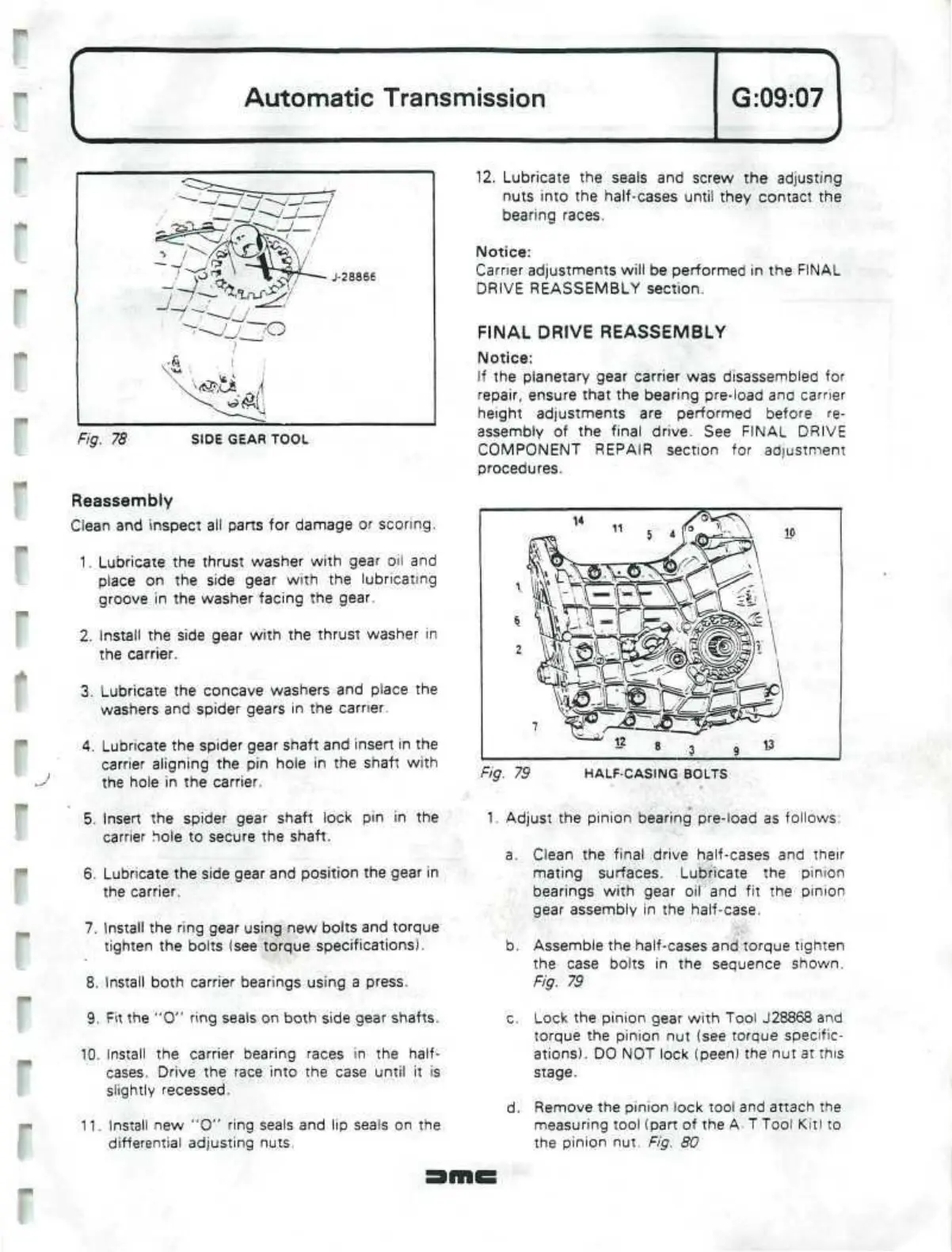

14

£*<

\

,f^£S9

13

Fig. 79 HALF-CASING BOLTS

5. Insert the spider gear shaft lock pin in the

carrier hole to secure the shaft.

6. Lubricate the side gear and position the gear in

the carrier.

7. Install the ring gear using new bolts and torque

tighten the bolts (see torque specifications).

8. Install both carrier bearings using a press.

9. Fit the "0" ring seals on both side gear shafts.

10.

Install the carrier bearing races in the half-

cases. Drive the race into the case until it is

slightly recessed.

11.

Install new "0" ring seals and lip seals on the

differential adjusting nuts.

1.

Adjust the pinion bearing pre-load as follows:

a. Clean the final drive half-cases and their

mating surfaces. Lubricate the pinion

bearings with gear oil and fit the pinion

gear assembly in the half-case.

b. Assemble the half-cases and torque tighten

the case bolts in the sequence shown.

Fig. 79

c. Lock the pinion gear with Tool J28868 and

torque the pinion nut (see torque specific-

ations). DO NOT lock (peen) the nut at

this

stage.

d.

Remove the pinion lock tool and attach the

measuring tool (part of the

A

T Tool Kit) to

the pinion nut. Fig. 80

Loading...

Loading...