r

Automatic Transmission

G:09:09

3. Fit the pinion gear assembly

in

the half-case

along with the differential carrier assembly.

Notice:

The carrier must be installed first and then the

pinion gear is placed in the case.

4.

Apply specified sealing compound to the half-

case mating surfaces and assemble the cases.

Torque tighten the case bolts in the proper

sequence. Fig. 79

Notice:

Apply specified sealing compound on the 10

diameter case bolts.

mm

5

Install Tool J28868 and torque tighten the

pinion shaft nut (see torque

specifications)

Lock the nut to the shaft by

peening

the end of the

nut. Remove the pinion gear locking

tool.

6. Fit the planetary gear carrier adjustment shims

m

the final drive case.

Notice:

Use the same shims that were removed

if

the

planetary gear carrier was not disassembled for

repair. If the carrier was repaired, use the shims

that were specified in the adjustment procedure in

the COMPONENT REPAIR section.

Install the bearing race using a brass drift. Ensure

that the race is fully seated in the case.

7.

Fit

a new gasket and install the planetary gear

carrier assembly in the case. Torque tighten

the mounting bolts (see torque specifications).

8. Perform the ring/pinion gear backlash adjust-

ment as follows:

Notice:

When performing the following adjustment,

the differential adjusting nuts must be adjusted

equally to maintain the proper carrier bearing

pre-load.

a. Remove excessive backlash between the

ring and pinion gears by loosening the

adjusting nut on the carrier bearing

opposite the ring gear, and tighten the

other adjusting nut an equal amount. Use

Tool J28866 to turn the adjusting nuts.

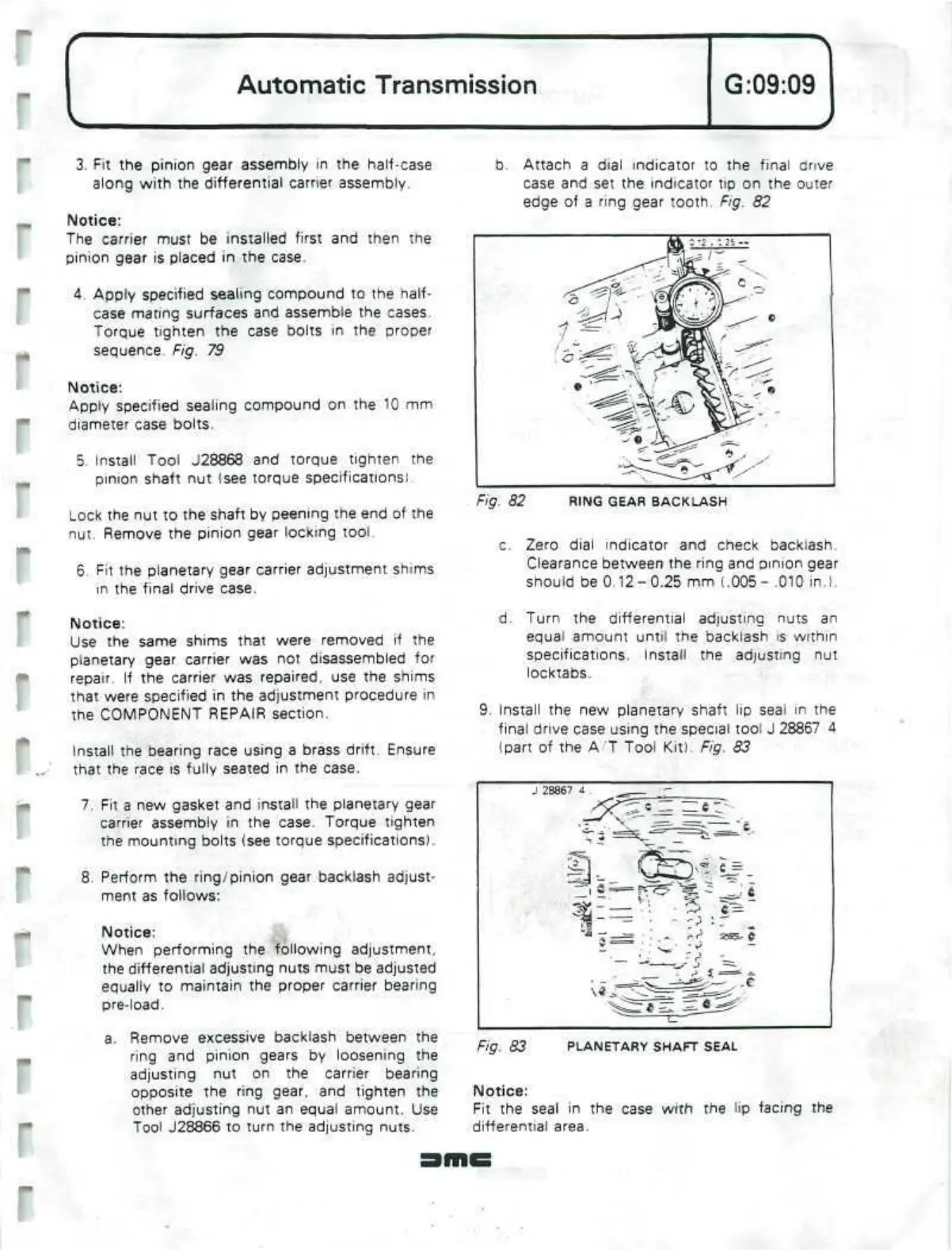

Attach a dial indicator to the final drive

case and set the indicator tip on the outer

edge of a

ring

gear tooth. Fig. 82

Fig. 82

RING GEAR BACKLASH

c. Zero dial indicator and check backlash.

Clearance between the ring and pinion gear

should be 0.12-0.25 mm (.005- .010 in.).

d.

Turn the differential adjusting nuts an

equal amount until the backlash

is

within

specifications. Install the adjusting nut

locktabs.

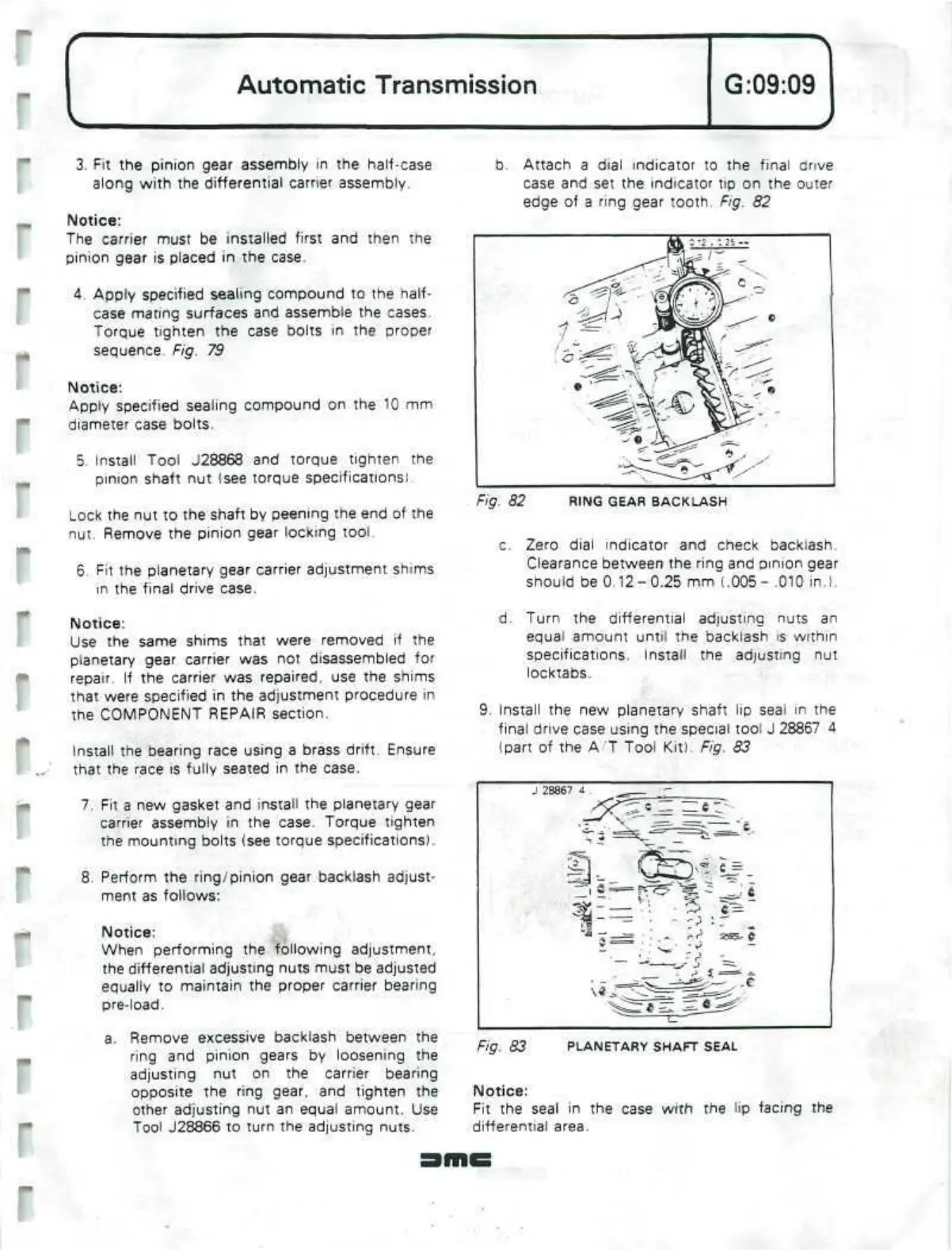

9. Install the new planetary shaft

lip

seal in the

final drive case using the special tool J 28867 4

(part of the

AT

Tool Kit). Fig. 83

J 28867 4

-*^5i

Fig. 83

PLANETARY SHAFT SEAL

Notice:

Fit the seal in the case with the lip facing the

differential area.

Loading...

Loading...