Heating and Air Conditioning

N:05:01

J

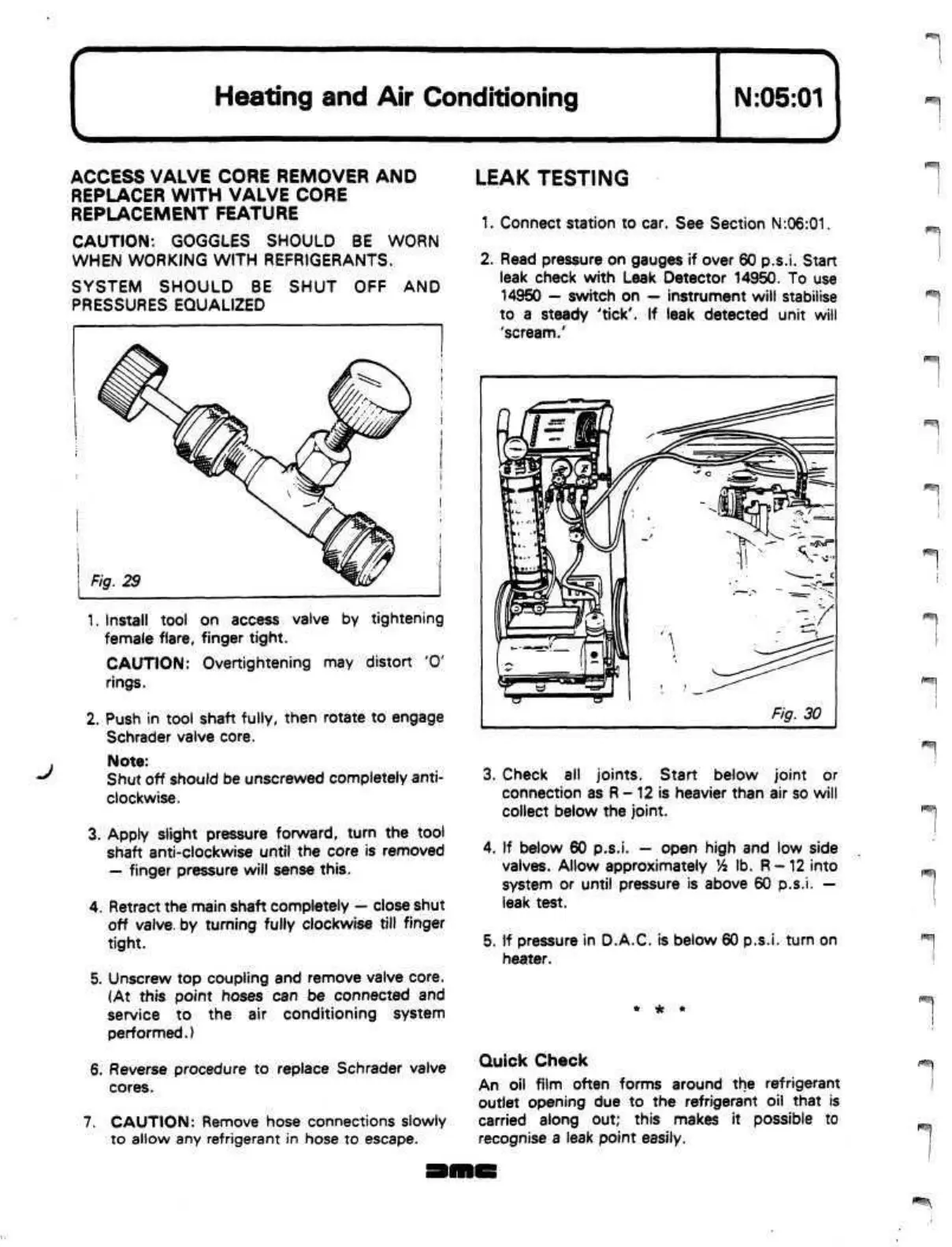

ACCESS VALVE CORE REMOVER AND

REPLACER WITH VALVE CORE

REPLACEMENT FEATURE

CAUTION:

GOGGLES SHOULD BE WORN

WHEN WORKING WITH REFRIGERANTS.

SYSTEM SHOULD BE SHUT OFF AND

PRESSURES EQUALIZED

Fig.

29

1.

Install tool on access valve by tightening

female flare, finger tight.

CAUTION:

Overtightening may distort '0'

rings.

2.

Push in tool shaft fully, then rotate to engage

Schrader valve core.

Note:

Shut off should be unscrewed completely

anti-

clockwise.

3. Apply slight pressure forward, turn the tool

shaft anti-clockwise until the core is removed

— finger pressure will sense this.

4.

Retract the main shaft completely — close shut

off

valve,

by turning fully clockwise till finger

tight.

5. Unscrew top coupling and remove valve core.

(At this point hoses can be connected and

service to the air conditioning system

performed.)

6. Reverse procedure to replace Schrader valve

cores.

7. CAUTION: Remove hose connections slowly

to allow any refrigerant in hose to escape.

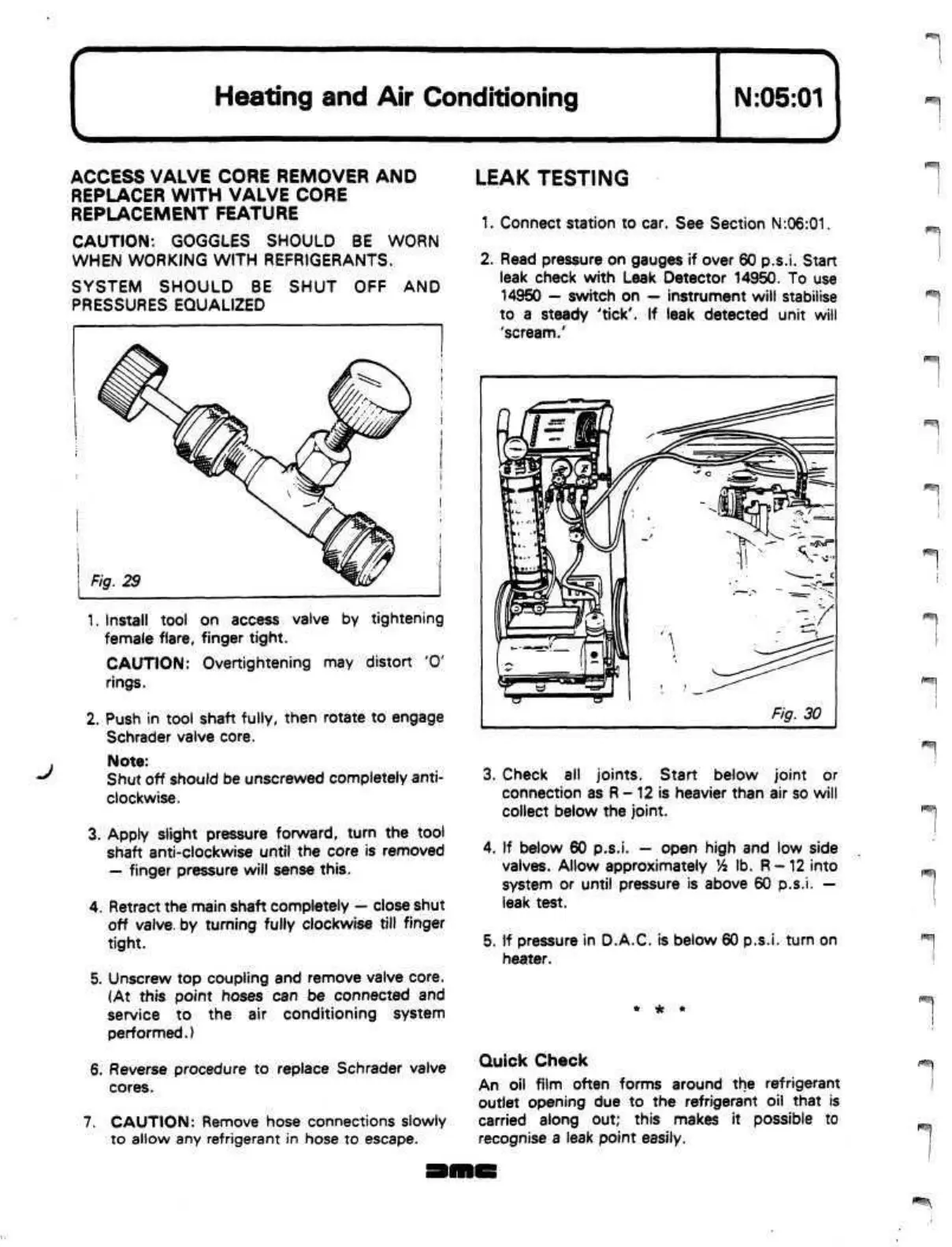

LEAK TESTING

1.

Connect station to car. See Section

N:06:01.

2.

Read pressure on gauges if over 60 p.s.i. Start

leak check with Leak Detector 14950. To use

14950 — switch on — instrument will stabilise

to a steady 'tick'. If leak detected unit will

'scream.'

3. Check all joints. Start below joint or

connection as

R -12

is heavier than air so will

collect below the joint.

4.

If

below 60 p.s.i.

—

open high and low side

valves. Allow approximately

!4

lb.

R

- 12 into

system or until pressure is above 60 p.s.i. —

leak test.

5.

If

pressure in D.A.C. is below 60 p.s.i. turn on

heater.

Quick Check

An oil film often forms around the refrigerant

outlet opening due to the refrigerant oil that is

carried along out; this makes it possible to

recognise a leak point easily.

Loading...

Loading...