Do you have a question about the Delta Elektronika SM 400-AR-4 and is the answer not in the manual?

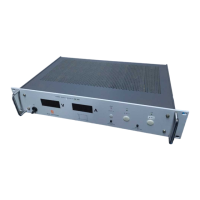

| Brand | Delta Elektronika |

|---|---|

| Model | SM 400-AR-4 |

| Category | Power Supply |

| Language | English |

Combines caution, fuse replacement, live circuits, and parts substitution rules.

Details on installation category and essential grounding requirements for safety.

Caution against exceeding specified input voltage and frequency ratings.

Guidance on correct disposal of Waste Electrical & Electronic Equipment in the EU.

Details on output modes, autoranging, and overload protection.

Information on input voltage range, current, and standby power.

Covers efficiency, CV/CC regulation, and output ripple & noise.

Methods for programming via analog, ISO AMP CARD, Ethernet, IEEE 488, RS232.

Using monitoring outputs and understanding status signals.

Description of relay outputs indicating fault conditions like DCF or ACF.

Configuration via SW1 switches and remote shutdown/interlock functions.

Programming speed, pulsating loads, and insulation safety.

Covers RFI suppression, operating temperature, and thermal shutdown.

Details on hold-up time, inrush current, and remote sensing.

Guidelines for connecting units in series for higher voltage.

Guidelines for connecting units in parallel for higher current.

Using units as building blocks in Master/Slave configurations.

How voltage and current limits protect the output and circuit.

Details on potentiometers and the internal cooling fan system.

Physical dimensions of the power supply unit.

Step-by-step guide for initial unit setup and operation.

How to activate and deactivate the Keylock feature.

Instructions for setting up analog programming via connector CON E.

Programming via ISO AMP CARD and digital interfaces.

Using monitoring outputs and understanding status signals.

Using remote sensing to maintain constant load voltage.

Using supplies as battery chargers and necessary protective measures.

Operating remote shutdown and interlock functions.

Connecting units in series using Master/Slave setup.

Connecting units in parallel using Master/Slave setup.

Considerations for parallel operation of fast programming versions.

Connecting units in mixed series/parallel configurations.

Optimal temperature and humidity ranges for operation and storage.

Precautions for using supplies in aggressive galvanic environments.

General maintenance advice, ensuring cooling is unobstructed.

Information on the cooling fan, dust, and thermal protection.

Guidance on contacting support and using the RMA form.

Troubleshooting steps for no output in manual control mode.

Troubleshooting programming issues and offsets.

Troubleshooting status output issues, including fuse checks.

Troubleshooting Master/Slave parallel problems and high output voltage.

Diagnosing issues based on OT, ACF, DCF, PSOL, and other LED indicators.

Advice for persistent issues and contacting support.

Information on factory calibration and when re-calibration is needed.

Procedure for calibrating digital meters using specific potentiometers.

Steps for calibrating current monitor offset and maximum current range.

Loading...

Loading...